the first production run starts by repurposing used wimbledon championship 2016 tennis balls into high performance speakers. hearO has built a production lab located in UK with a tailor-made hydraulic press. cutting specialists in northampton have helped develop tools using techniques from fashion, automotive and aviation industries, with custom 3D printed guides.

hearO’s speaker comes packaged in an upcycled tin case reminiscing the classical tennis ball tubes

hearO prepares, assembles, tests and packages the speakers in their studio located in london. the speaker’s high performance was achieved by optimising the battery life, volume, sound quality, and other properties developed alongside the innov8 group in paris. the rubber of the tennis ball absorbs vibration and enhances audio clarity, while the fibonacci spiral speaker grill pattern enables optimal sound projection. the hearO speaker rests independently on a charging cradle with a 360-degree magnetic connection and comes packaged in an upcycled tin case.

the one button connectivity makes it the perfect portable speaker companion

true to the nature of the product, hearO’s desire is for the customer to keep the tin and find other uses for it. hearO reimagines what was once a throwaway object into a desirable product that has real value and purpose. the studio’s philosophy is to challenge and rethink consumption in a more sustainable way.

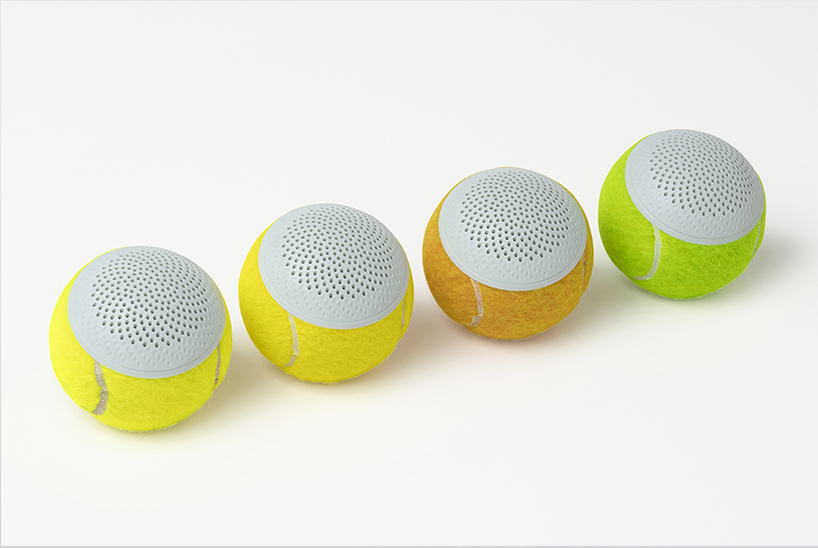

its organic fabric dye experiments adds character and tailor-made nature to each product

wimbledon championship 2016 repurposed balls in different weathered conditions

hearO unlocks the potential of leftover tennis balls, moving away from the throwaway habit

these household applications result as an interesting product of a creative reuse

a portable speaker housed in a functional piece of tennis history

developing customized tools for the hearO speakers

3D printing lead parts of the design process

cutting bed and 3D printed guides on the custom-built hydraulic press

hearO’s upcycled packaging tins take on multiple functions

balls are cut in Northampton and each speaker is assembled in the design team’s london studio

click on the button above to purchase the product on the designboom shop!

designboom has received this project from our ‘DIY submissions‘ feature, where we welcome our readers to submit their own work for publication. see more project submissions from our readers here.

edited by: apostolos costarangos | designboom