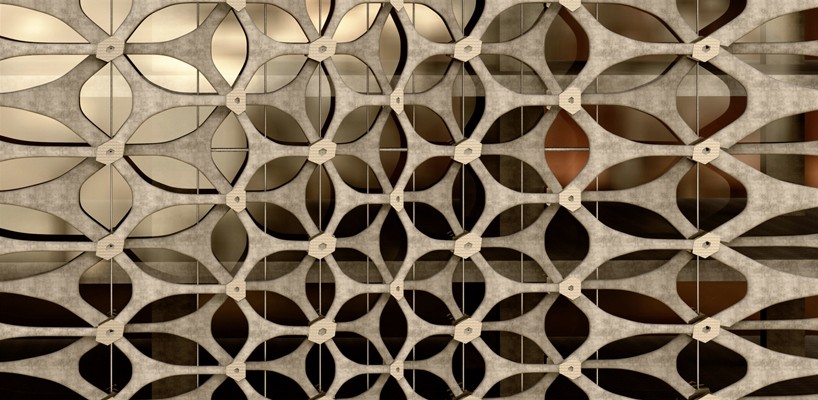

exploring the field of robotics, ron culver and joseph sarafian from form found design have developed a self-supporting façade shading system that removes the geometric repetition of traditional concrete casting. this method is derived from a parametric workflow that employs the precision of six-axis industrial robots and the flexibility of fabric to create more effective designs.

the final cast is a result of the precision of six-axis industrial robots and the flexibility of fabric

featured at the façade tectonics world congress in los angeles, and the now next future conference by the AIACC, form found design’s project is a means of achieving variation and effective labor in an otherwise repetitive façade industry. indeed, conventional use of concrete as a casting technique has proven to be arduous and inaccurate – making this material unsustainable and inefficient for façades with complex, organic geometries. therefore, such parametric design must be cost-effectively executed and reduced via a precise digital-physical workflow which ultimately meets the requirements of conventional techniques.

perspective view: the final cast resembles a wishbone-like pattern covering the entire façade

through this technique, robots position the fabric which acts as a mold for a concrete pour.reinforcing cables are then cast within the bone-like shapes of the façade to deliver tensile forces between members. construction is underway for the palm springs pavilion which is a self-supporting compression structure, built using the same process. this pavilion will debut in march 2017 and is led by sarafian and culver, alongside steve fuchs.

reinforcing cable are integrated within the fabric framework

view of the canopy

elevation – digital diagram

bolting detail drawing

designboom has received this project from our ‘DIY submissions‘ feature, where we welcome our readers to submit their own work for publication. see more project submissions from our readers here.

edited by: lea zeitoun | designboom