designboom interviews designer of the exiii bionic arm tetsuya konishi

all images courtesy of exiii

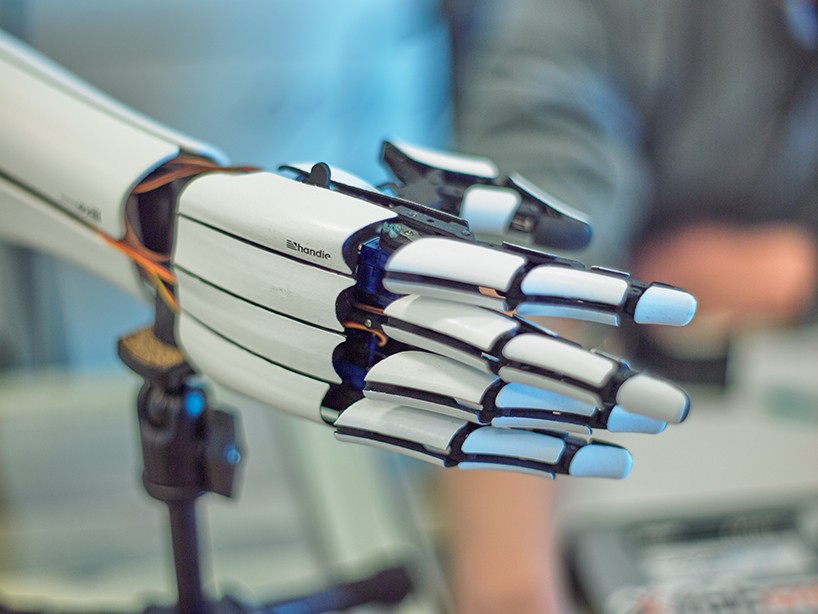

japan GOOD DESIGN award: exiii is 3D printing a new landscape of prosthetic arms in japan with their open sourced bionic hand ‘hackberry’. the modern prosthetic has advanced flexible wrists that enable for more variable movements, smaller palms to make it more appealing to women and an increased compatibility to an assortment of different batteries.

introduction to exiii bionic arm

video courtesy of exiii

the company is made of up three founders – software engineer genta kondo, mechanical engineer hiroshi yamaura and industrial designer tetsuya konishi. the team has greatly reduced the material cost by utilizing 3D printers, and also offering choices of design and function to various user preferences. together they’ve created a platform where developers and artificial arm users from all over the world build jointly the ultimate robotic prothetic arm. for such an intuitive design and adaptable software platform, the exiii ‘hackberry‘ bionic won the 2015 g-mark japan GOOD design gold award. the company has also open source all the hardware and software files on a github page, where anyone can find the 3D models and modify them.

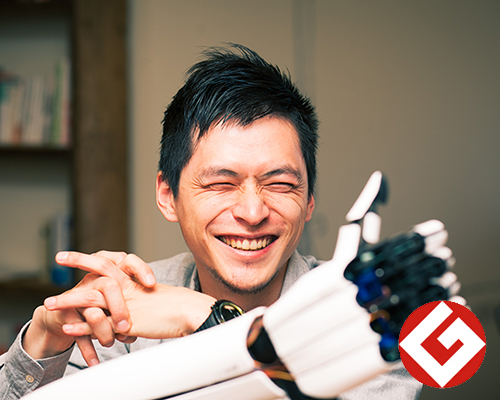

designboom sat down with with tetsuya konishi to discuss reasons for open sourcing the project, the future of 3D printing, and what’s next for exiii.

the founders tetsuya konishi, genta kondo and hiroshi yamaura

designboom: when did you start with the development of the ‘hackberry’ arm? and why?

tetsuya konishi (TK) : we have three members and two of them worked at panasonic and the other person worked at sony. when we started exiii in 2013, we were working for those companies. of course all three of us quit now, but back then we were working for all of them.

DB: how many variations did it take to get to the final model?

TK: I think the current one is the fifth version.

DB: what was the most difficult part of the development?

TK: well the first most difficult part was the legal issues because we were producing these prothetic arms using 3D printers. in Japan relevant law hasn’t been enacted yet, so we resolve the legal issues.

the team programming inputs into the arm

DB: in what sense? was it a durability issue?

TK: yes, one of the issues was durability. also, another issue was if we can legally sell this as a prosthetic arm or not. there’s requirement for personnel who measure people with disabilities for prosthetic arms to be licensed. those are some examples of the legal issues.

DB: so how have you resolved this problem?

TK: as you know, there is a dyson award and we created these prosthetic arm in order for us to apply for it. we won this award, and I believe we were the first japanese to do so. because of the award, we got know many people, which introduced us to even more people. this chain of references continued and made it easier for us to work. so now because of this, we are aloud to work with national government related agencies, to conduct our testing. this status allows us to work more effectively.

the exiii ‘hackberry’

DB: what it always a thought that 3D printing would play a major role, or was there a plan to manufacture two or three arms for everyone?

TK: well, from the beginning we decided to use 3D printers. in the past, producing hardware was difficult. it was easy to develop software, but when it came to hardware, you have to think about how to build a product. now, 3D printers are easily available, and by using them we can easily carry out different prototypes. when we created this prototype, the cost was cheaper then we had expected.

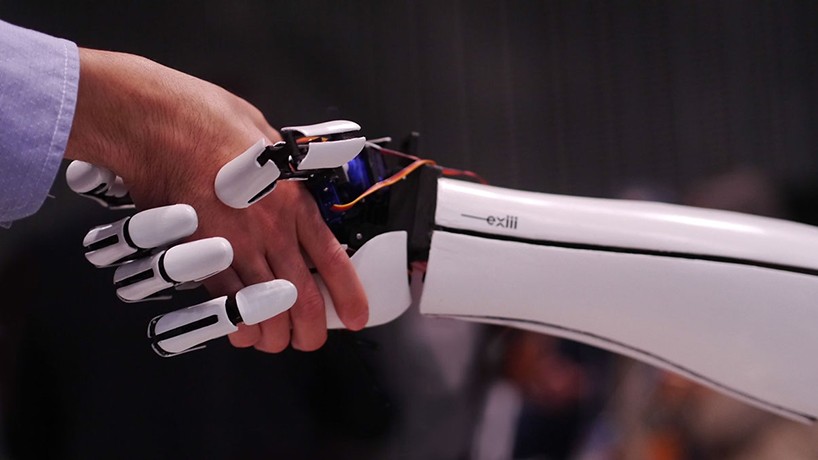

the prosthetic reacts to muscle triggers

DB: the personalization is the strongest aspect of 3D printing, taking measurements and make it on location.

TK: very true and if we choose to do so, we can make a 3D scan of the person with the disability, take the data from the scanning, and then create the prosthetic arm. but thats not what we are doing yet. we are producing more for general purposes, fit for many people with different sockets, so we don’t take measurements and mass produce. we chose to open source the arm. this combination of 3D printing and an open source platform creates higher possibilities. in the open source landscape, we are quite rare. usually, if you offer open source hardware you use an STL file which cannot be edited. in our case, we use formats open to editing. companies that are making hardware who want to make a profit don’t use these types of open formats. we want users and others to edit freely and modify as they see fit.

DB: you don’t want to make profits?

TK: we are not interested in profits by selling anything. at the moment we are still exploring possibilities, but for example android was developed by google, but had to invest billions of dollars to develop. then they decided to provide it open sourced.

the bionic arm has joints in every finger and wrist

DB: do you have any other investors behind the company?

TK: when we first established this company, there was no other outside investment. now google has given us a sizable investment fund to further the project and working capital. at the moment we are thinking how we can grow this business.

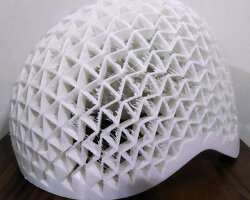

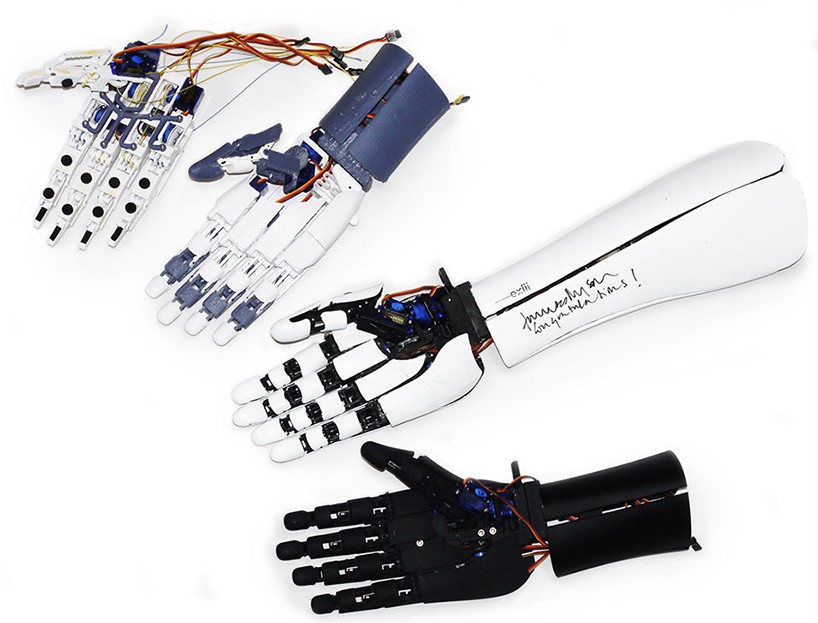

the varied prototypes

DB: what kind of return are you expecting? are you thinking of patenting something?

TK: that is one possibility. in the past, software was usually offered as open source, and then various business models were discovered. but when it comes to open source hardware, I think there are a only handful of examples where profits are actually being made. however, profit-making from open source hardware could become possible. we don’t want to be seen as pure charity because being one may not be sustainable.

DB: is there a difference in the software for various ages of people?

TK: because we are offering this as open source, many others have shrunken our product for children. we are just making a product just for adults. what we believe is that we can seed free viable roots in the soil. then in the world, there will be people that can take those seeds and grow it into something better.

DB: so where is the design aspect in this?

TK: everything. we have such a dynamic team, that if one of us exits, the project cannot continue. the simple aesthetic does not make this a meaningful product. if the interior mechanics aren’t good. the design isn’t good.

DB: have you designed something similar before this project?

TK: one of team members who is the software engineer was conducting research about prosthetic arms at the university of tokyo. he left because the project at the university wasn’t viable, and expensive. but we also noticed that university research is not looking at users. university research is trying to find a topic which a scientific paper is easily written. those projects didn’t include any design aspects for the users. one thing I must mention is that the market for prosthetic arms is very small. in all of japan, the market is less than 10,000 people. so mass production, doesn’t define any learning curve, or influence cost reduction. a new setting must be found in order for the users to gain access to these kinds of artificial arms and hands.

the ‘handii’, exiii’s first model

DB: are you continuing to develop this model or you moving on to something else?

TK: the target that we set is to increase the share of electric prosthetic arms from the current 1.7% in japan to 20%. that’s our target. I think that the european share of electric prosthetics is already high, and dominated by german companies, so we’ll be only focusing on japan.

made of lightweight plastics

DB: is your design work finished for this project?

TK: we are only designing and producing to this point only. then, we’ll start creating elbows, and shoulders.

DB: do you plan to recreate the whole body in the future?

TK: of course we hope to do that. if we provide a whole open source electric body system, it will attract more attention, and we definitely hope to do that. the most important asset that we have, is the people in the oncology system. we are now seriously thinking about what needs to be done to expand this ecosystem and community. we are thinking about the next step.

the different mechanical joints

DB: no one before you has done this?

TK: not exactly before, but about the same time when we started exiii, there was a company called open bionics which were producing electric prosthetic arms, and there’s an association called E-nable. this association distributes prothetic arms to children, but don’t include any motors.

DB: in a way, your team is truly unique idea in japan.

TK: we communicate with both, in a none competitive way because it’s such a small market.

DB: are you working on any other side projects right now?

TK: well, I work on some commissioned work. I like to focus on wearable devices. I’m working with other companies on many other wearable devices. in designing wearable devices, you need to think about many other things. I have to take into consideration many aspects, because what I’m designing are being worn by people everyday. that’s why I think the prosthetic wearable is the ultimate wearable.

DB: will winning the g-mark japan GOOD design award help further development of the ‘hackberry’ arm?

TK: I think so because recognition for the g-mark is so high, that if we can win that kind of prize, we can expect an immediate expansion of the prosthetic arm platform.

DB: where do you see 3D printing going to help future products?

TK: in my field, I think people in the future will be able to make anything they want exactly the way they want it. as of now, in order for someone to create a CAD design, they have to learn the software and acquire the basic skills to form it. but as software iterations continue to get better, and 3D printers become less and less expensive, more people will want to make their own products. but I think 3D printing is perfect for tiny markets like prosthetic arms because each user has specific requirements that need to be customized exactly.

the exii hackberry is a winner of the 2015 japan GOOD DESIGN gold award, presented during tokyo designers week 2015.

the GOOD DESIGN award was founded in 1957 by the japanese ministry of international trade and industry and is hosted by the japan institute for design promotion. the ‘g mark’ emblem reflects comprehensive design values and principles that aim to enrich lives, industries and society.

Save

Save