KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

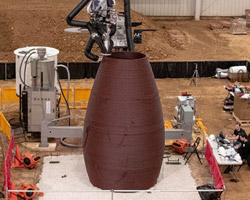

happening now! with sensiterre, florim and matteo thun explore the architectural potential of one of the oldest materials—clay—through a refined and tactile language.

developed by tomasz patan, the mastermind behind Jetson ONE, the personal hoverbike levitates and glides in the air with ease.

connections: +290

explore the series of high-tech toys and devices designed with modern features for adults.

its external body features abstract semi-circles in white and gray over a warm gray base, subtly evoking the ripples and waves of flowing water.

connections: +430

designboom interviews chief design officer gorden wagener to discuss the ‘frunk’, AI agents that detect the driver’s moods, and more.