ZE123 x DesignBoom x Colombo by Ettore Ambrosio from italy

designer's own words:

Columbus Contest

The design effort, the collective of Industrial Design ZE123, to handle the new Columbus offers an easy realization by both the industrial point of view of cost and technically.

You tried it, through intuition, to minimize material waste and to double the production of the product through a single process.

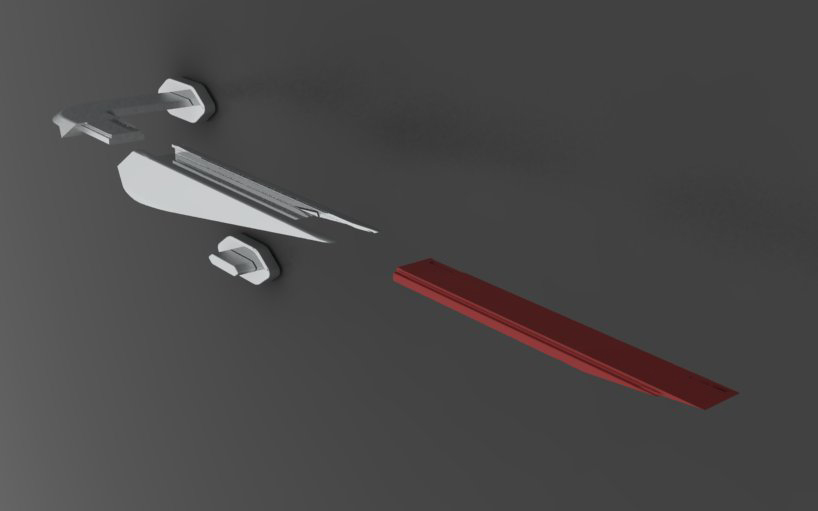

The intuition is indeed to try to get two handles from a single aluminum profile almost to zero by reducing the waste of material, thereby optimizing both costs of the times.

From this idea, he later moved on to handle the design phase of reaching a preliminary design, through which a section prepared by ad-hoc for the object through a cut that partitions the profile you have two handles.

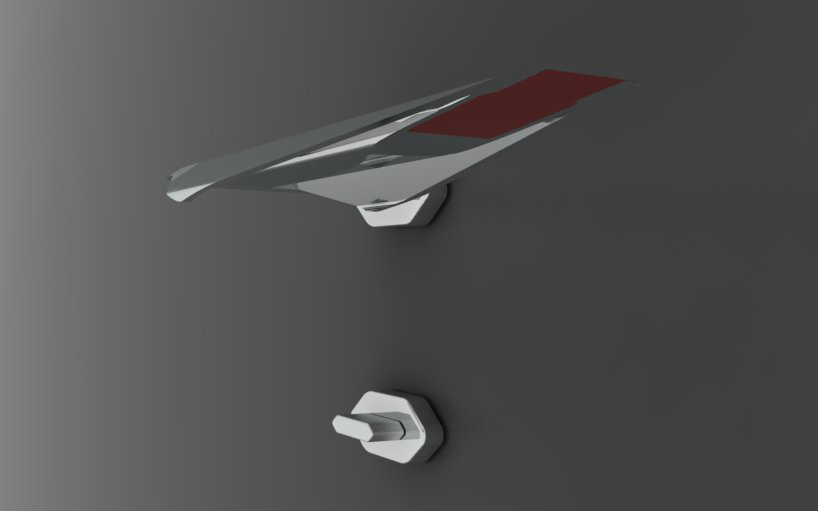

Looking at the result, it is then passed to a further evolution of the object, the present scenario of the market handles, displaying the subject independent of that will be then the door or window over which it is applied, unless, not Whether a uniquely designed handle for a particular door or window.

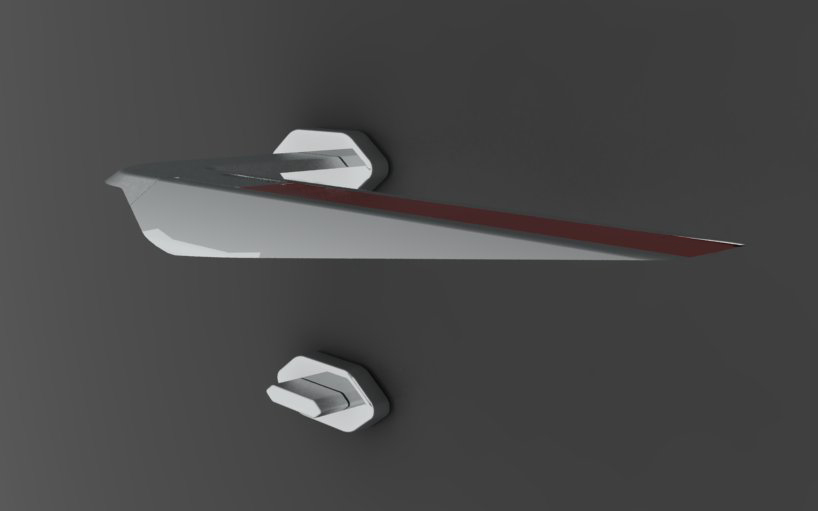

By observing this peculiarity has tried to create a handle that became universal, whatever the door or window on which we must then apply it, imagining the shape of the object capable of receiving an interlocking 'evidence to personify the handle according to the port or the window on which you decide to use it.

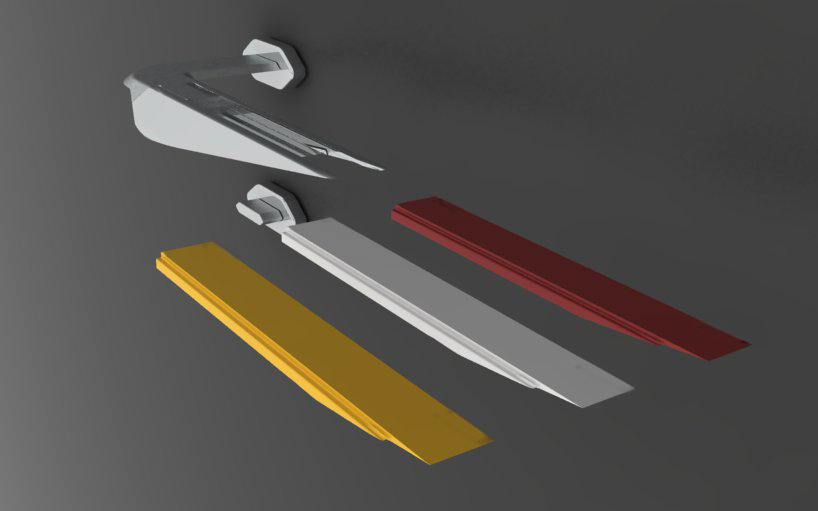

In our proposal the element to be embedded, must be able to have any type of finish or color you want by color or finish of the door, so that you can include a handle designed specifically for any type of door. If the port is in some type of wood, whether it is color, if it is glass and so on. etc.. we have the finished item to be collected the same type of wood or glass or the same color and so on.

From this other insight is then resulted in the final geometry of the aluminum profile without any additional process that already provides housing element to match the door or window.

The executive design, we then pushed the last intuition, to use the same accommodation for stationery to fit even the end of the handle, the technical side, the one where is the rotation that allows you to close or open a door or window. In doing so well the end part can be drawn in order to have more variations on further customization.

With our project proposal, the object handle is reworked and decomposed, becoming an object not more static but a living thing with which to interact and that the opportunity over time to be changed or customized without having to change it if you decide to change the type or finish of the door.

From the morphological point of view, we tried to draw a handle that would bind well with the new trends in contemporary interior design and furniture, where he places increasing emphasis on the shapes with sharp corners, clean lines and sensible.

By creating an attractive and symmetrical object at any angle you look at it, the exact sizing based on the ergonomics of the human hand.

Although it should be noted, as in this proposal, the morphology of the object, although important, has a valence less important than productive idea, because having to prepare the aluminum ad-hoc to produce the item, simply draw the section of the profile in a different way to get the different shapes, the important thing is the operation of the system.

1

2

2

3

3

4

4