Volvo pavilion: Almond by disguincio&co from italy

designer's own words:

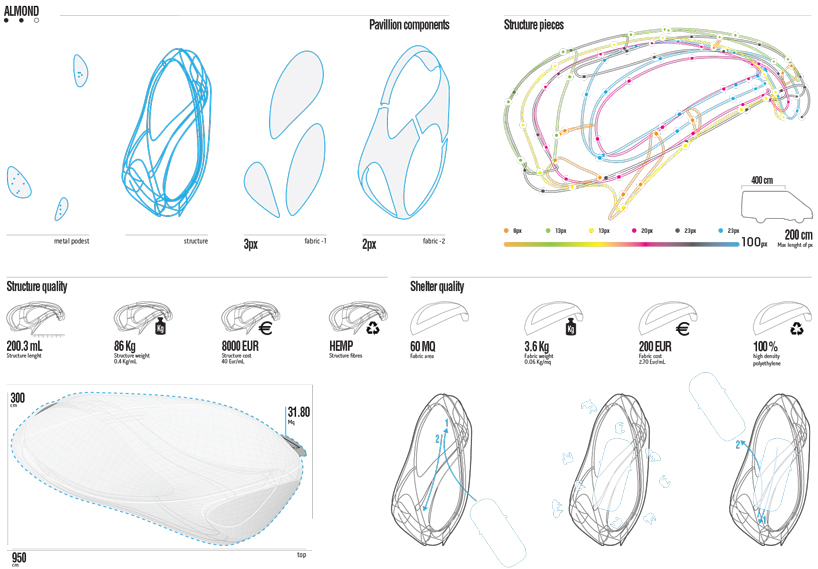

An ultralight fiber-composite structure that traces a tri-dimensional flow in space as a scenography for the new Volvo V60 plug-in Hybrid car.

The pavilion with its geometry and in a specific way with its apertures, wants to frame special views of the car. The same goal is reached using different opacities for the covering fabric, that create blur effects to attract the people to the core of the installation where the car waits to show its qualities. The car is on a street level, no obstacles, the public can enter into the shelter and walk around the car, that could be easily parked inside because of the large apertures on the main side of the pavilion.

The pavilion could be defined by 3 main components: the structure, the covering, and the electrical service:

Structure.

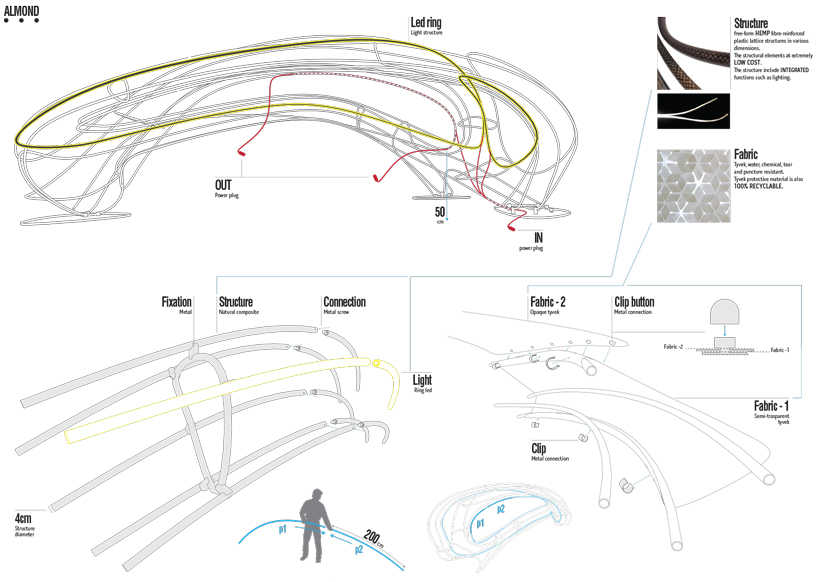

The structure is characterized by a series of fiber-composite pipe loops, a SuperTex(TM) technology that is allowed to be CNC manufactured. The pipes are made of hemp fibers and natural resins to guarantee sustainable performances to the structure in terms of recyclability, cost and weight (important for logistic reasons). Each loop is subdivided every 2 m to guarantee an efficient storage of the pieces. They are bond together thanks to specific steel joints. Three loops deve- lop the whole shape, then there are three more series to reinforce the system. They are bond together through the designed intersections where steel joints assure the fixations. The connection to the ground is guaranteed by three steel platforms, equipped with a series of connections to fix the pipes.

The pipe length of the whole system is about 200 m for an approximate weight of 86 kg, and cost of 8000 Euro.

The structure could be assembled by few people without danger because of the extreme lightness.

Covering.

A fabric layer is extended over the structure to protect and better define the interior of the shelter. The surface is parti- tioned in two areas with different opacity: three big opaque ellipsoids and the semi-transparent in-between parts that unveil the structure. The fabric proposed is Tyvek®, made from high-density polyethylene (HDPE) and it is 100% recyclable. It is lightweight and exceptionally breathable, strong, durable and long lasting. It Provides superior water resistance, while allowing moisture to escape, and It blocks 99.8% of the sun's damaging UV rays that can fade interior and exterior surfaces of the car.

The fabric is fixed to the structure by simple steel clips, in the same way the different typologies of fabrics are joined together through a series of clip buttons easy to handle during the assembly process. In total there are 60 sqm of fabric, easy to storage in few boxes (just less than 4 kg) for a cost of 200 Euro (just the material without shaping process and equipments).

This kind of surfaces give the possibility to project videos, images, texts on the pavilion, transforming it in a big tri-di- mentional screen. The projectors could be fixed inside, on the tubular structure and plugged to it (see electrical servi- ce).

Electrical Service.

The language of the pavilion is the language of floating wires: the structure is partially equipped with electrical cables that run into the pipes, literally inside. One single plug-in to manage (with a central unit) all the needs of the pavillion: lights, projectors and of course, the power supply for the car. In this way the pavilion itself is an expression of this technology, the system integrates all the parts. Even the lights are 2 loops that follow the the flows of the structure to better define the shape of the whole: two led rings directly connected to the power of the pavilion. The power plug to charge the car emerges directly from the structure, like an extention of it, giving the opportunity for a pure connection between the shelter and the car.

Almond View

Almond Prospect

Almond Structure

Almond System Detail