Solar Extruder by studio swine from uk

designer's own words:

Solar Extruder

Driven by a curiosity about the Sea and it’s potential for future manufacturing we have designed a device to melt plastic collected onboard a boat in a completely self-sustaining system. The device could be installed on boats to make or repair new items at sea from plastic waste without the need to carry fuel. It could also be used at the beach or inland to locally recycle waste.

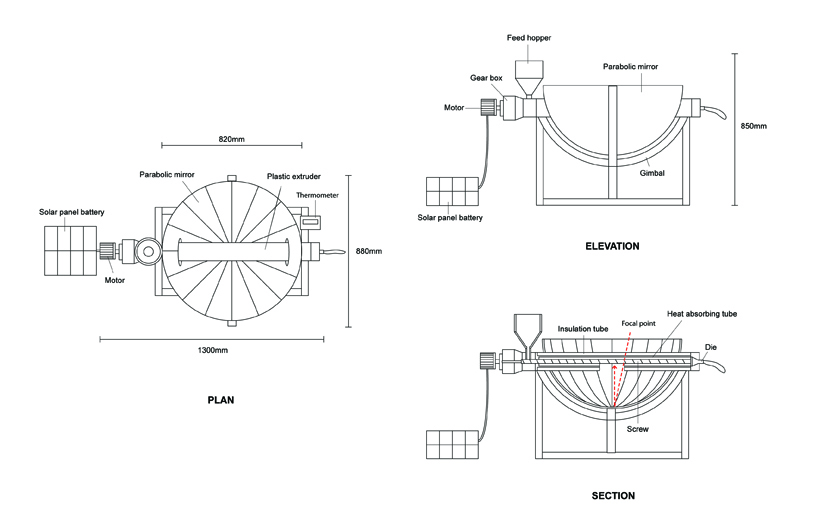

The Solar Extruder consists of an extrusion machine heated by solar oven. The oven melts the plastic at approximately 200°C. A steel tube absorbs the heat at the focal point and conducts it along the barrel with an outer insulation to maintain a steady temperature. The whole device is weighted low and gimbaled to keep it steady at Sea.

For Lexus we will make the Solar Extruder in Shanghai where our studio is currently based, we will install the Solar Extruder on a fishing boat and create and some objects at Sea. The Milan exhibition would consist of the Solar Extruder and accompanying objects and documentation of the device in action.

The culmination of 2 years researching sea plastic and making devices for its collection and processing has led to the solar extruder. Existing technologies are synthesized in a completely new way for a new purpose. The conversion of energy from a solar oven runs at an efficiency of around 80% as opposed to solar panels that run at an efficiency of around 15%. This enables the sun to be harnessed for melting plastics fished from the Sea. A Solar panel is used to charge the large battery that drives the extruder screw- the intervals between extrusion for collecting and preparing plastic being long enough to ensure time to charge. A hand crank can substitute the motor if required.

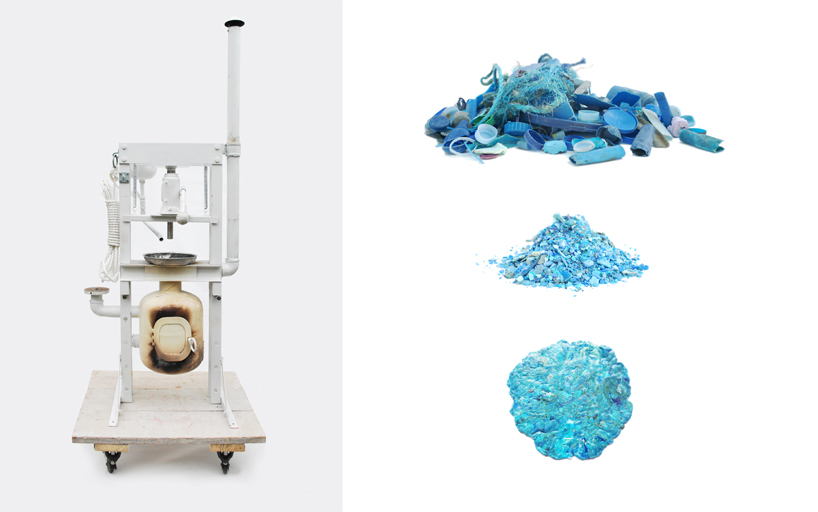

Sluice device for separating plastic from organic material

Press and Furnace for melting plastic

[jwplayer config=”mplayer” width=”818px” height=”600px” file=”https://static.designboom.com/wp-content/compsub/333932/2013-10-06/video_1_1381043239_6d090e8427ade57a9570a54a9a17a103.mp4″ html5_file=”https://static.designboom.com/wp-content/compsub/333932/2013-10-06/video_1_1381043239_6d090e8427ade57a9570a54a9a17a103.mp4″ download_file=”https://static.designboom.com/wp-content/compsub/333932/2013-10-06/video_1_1381043239_6d090e8427ade57a9570a54a9a17a103.mp4″]

video

Filling mould with plastic

Sea Chair

Rendering of Solar Extruder

[jwplayer config=”mplayer” width=”818px” height=”600px” file=”https://static.designboom.com/wp-content/compsub/333932/2013-10-06/video_2_1381043239_e8dfa001045b9e0d37513fb4bea8f8df.flv” html5_file=”https://static.designboom.com/wp-content/compsub/333932/2013-10-06/video_2_1381043239_e8dfa001045b9e0d37513fb4bea8f8df.flv” download_file=”https://static.designboom.com/wp-content/compsub/333932/2013-10-06/video_2_1381043239_e8dfa001045b9e0d37513fb4bea8f8df.flv”]

video

Solar Extruder in Plan, Section, Elevation