plastic chic with a rubber egde by rajvi mehta from india

designer's own words:

locally producible, recycled material, easy to wear, sturdy, comfortable, and different: are the keywords on which the shoe was made.

The target customer is a working woman for whom it is easier to walk in flat footwear, without any fastenings: zipper, buckle, or tie ups. Thus the slip-on type of a shoe is preferable.

Two things that create waste in any urban city are: bicycle tyres and plastic bags. These are also available in variety. Plastic bags of every colour and quality make a wonderful choice of raw material. Also the tyres come in varying patterns of the grip which provide the possibility of allowing the customer to chose and customise their own shoes!

construction:

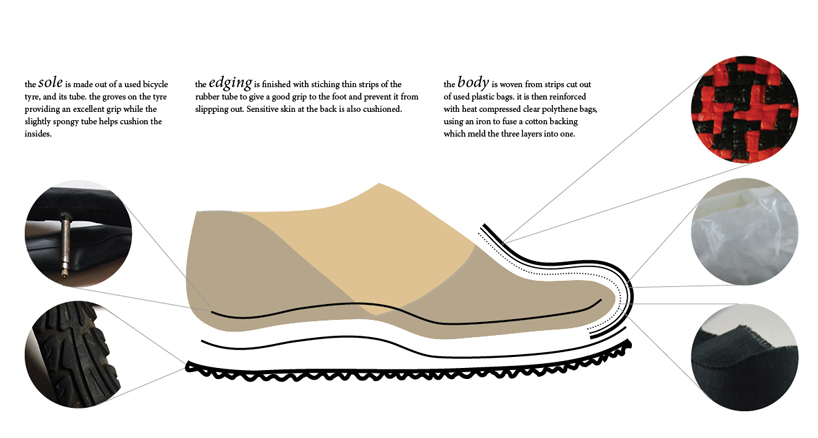

The base of the sole is made of a used bicycle tyre, the grooves in the centre form a grip. First, parts of the tyre are cut and stuck with ‘neoprin’. The shape of the sole is cut out of it. Then sole is flattened by heating and cooling under pressure. The inside area of the sole is made from the inner tube of the tyre, which is soft and has a grainy texture.

The body is made using strips of the thin plastic bags we get every day from departmental stores. The strips are then hand woven into any pattern like houndstooth, or twill. It does not need a professional loom, just a spiral bound edge of a notebook can be a perfect loom to work on! To make it sturdy, some clear bags are layered underneath it and fused to the woven pattern, with thick cotton fusing. Ironing these layers together melds them into one. Strips of the rubber tube are used for the edging.

Overall, it’s a very easy locally producible process that leaves room for customisation of colour, weave, pattern and also silhouette.

customised weaves the raw materials used

the raw materials used  details that make it interesting

details that make it interesting the result: comfortable upcycled everyday footwear

the result: comfortable upcycled everyday footwear