design of low cost solar lantern for farmers in rural india by rohit from india

designer's own words:

Project description:

Aim of the project is to design and develop a solar lantern which gives maximum light output with more power back-up as compared to other competitor’s product in the market. Some of the considerations about the project were how to make this lantern more light weight and Eco-friendly. As per the preliminary research done, it was found that in India more than 60% percent of villages are facing power failure and lack of power supplies. Thus this project has got a great potential as it uses solar energy for its power generation. The project study mainly focused on light emission, battery selection, light source, form and function, aesthetic and ergonomics of the product.

Work background:

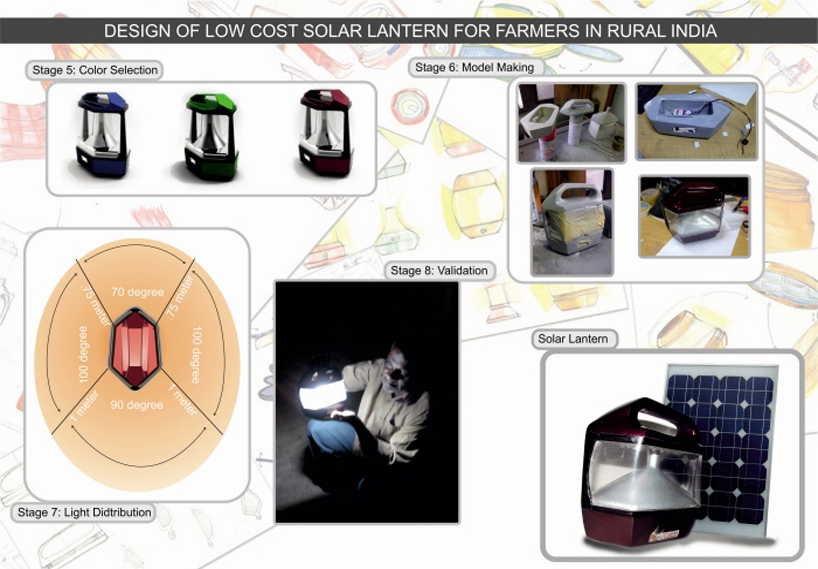

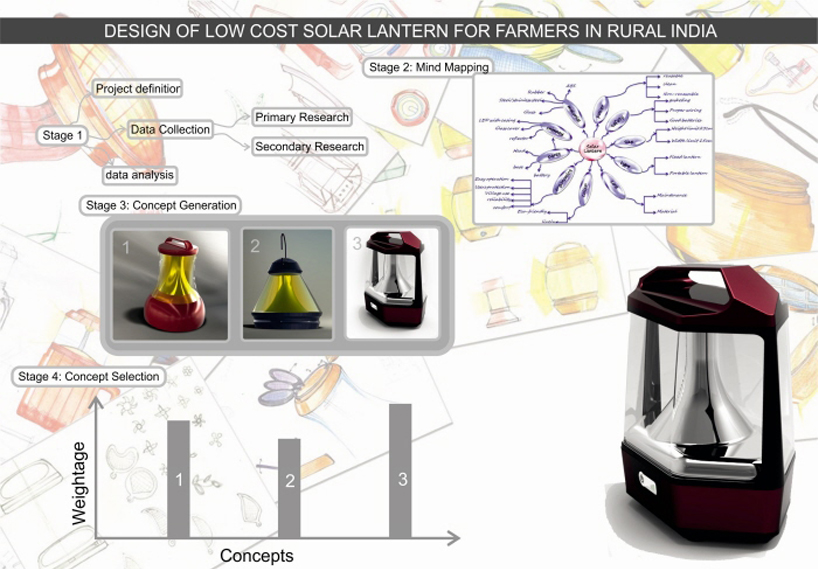

Based on the output developed from QFD, concepts were developed with major importance given to light distribution, ergonomics and aesthetics. Using weighted ranking method one of the concepts got selected. Major innovation happened in the design development of reflector and led placement which was important to generate maximum light output. Reverse engineering and material study of present lanterns helped in deciding the appropriate material for the lantern parts. A prototype was made test for proof of concept. This prototype was tested with farmers for validation. This validation points guided for further development of the product.

Key parts in the lantern are handle,base,chimney with frame, led panel and reflector. Among this components major innovation happened in design of reflector. Basic idea was that the shape of the reflector should be the factor which will decide the light distribution. As per proof of concept, the shape of reflector is finalized as a form transition of circle to hexagon. The light given out from led will hit the side of the curve reaching the hexagonal base. Front of the lantern will have a wider angle, thus it distribute maximum light angle. While the back end of the reflector is narrowed and it gives less light distribution(light distribution study mentioned in the second image will explain this point).

Manufacturing process and material selection:

Material for handle, base and the chimney frame is selected as ABS plastic and it can be manufactured by injection molding process. Reflector is also made of ABS with same manufacturing technique but it has to be electroplated to create a reflecting surface. Chimney is a clear glass material which can be recycled glass material. Battery used is lithium battery which gives 10 hours backup and can be easily charged. This battery us available in market.

Working:

LED is fixed under the handle of the lantern using LED panel support. Light from the LED will hit the reflector and gets distributed outwards. The main advantage of placing the LED hidden under the handle is because the light emitted will not create any disturbance to the users eye. An ergonomically designed control system holds an On/0ff key, battery charge indicator and a universal knob to connect mobile phone, radio etc for charging.

Advantages of the design:

- The shape of the lantern controls the light distribution, which gives correct path guidance to the user.

- Lithium battery is used which gives 10 hours backup.

- Material selected makes the lantern less in weight.

- Manufacturing cost for this lantern will 1200INR. Thus the customer can get this lantern in much lower margin than other competitive lantern in the market.

product study, preresearch and indepth research of the product, ideation and concept development, proof of concept and concept selection