chroma by alberto zamarron from spain

designer's own words:

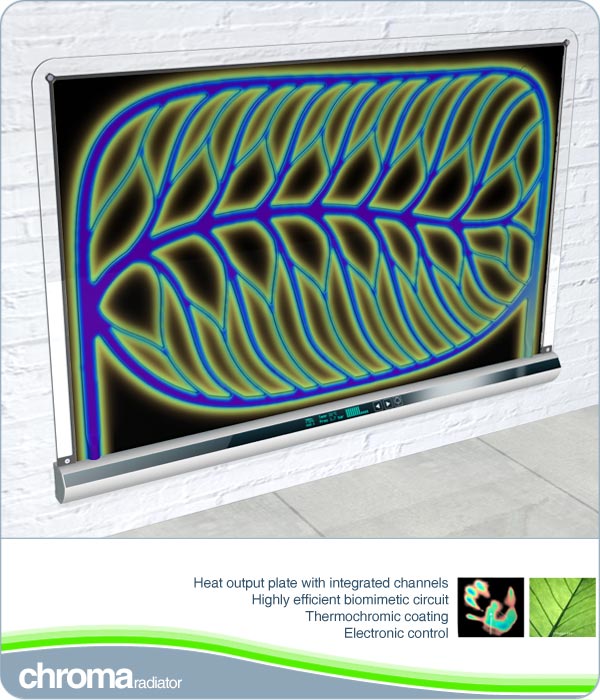

Chroma is a thin, light and bold radiator whose look evolves during its operation and applies existing technologies from other fields.

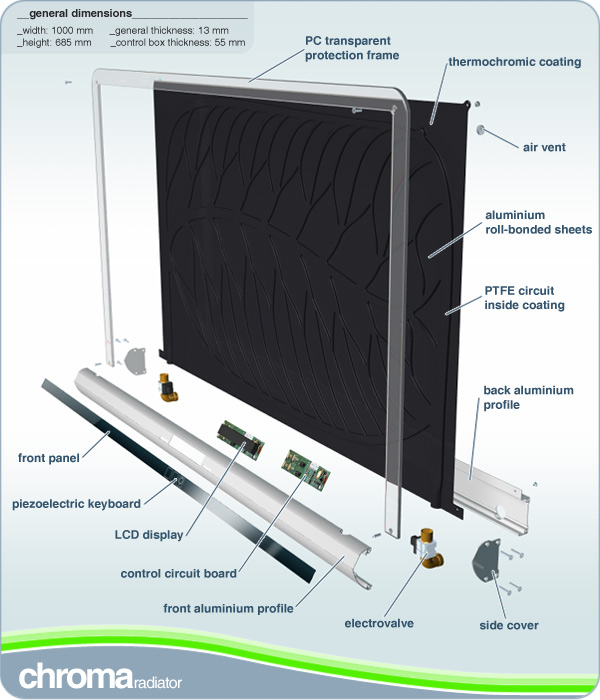

The radiator heat output plate is made of two aluminium sheets using Roll-Bond process, applied in products like solar panels or automotive heat exchangers. Basically, it consists on 3 phases: print circuit using antiadhesive ink on the lower sheet, heat and roll both sheets in order to weld them and, finally, inflate the internal circuit with pressurised air. This allows a great design freedom and variable section channels. A PTFE coating is applied internally in order to avoid corrosion.

Channels design is inspired by nature where, for example in leaves or bloodstreams, flow channels have to provide heat and mass transfer efficiently. Thus, circuit design is aimed at optimized thermal efficiency and minimized pressure drop.

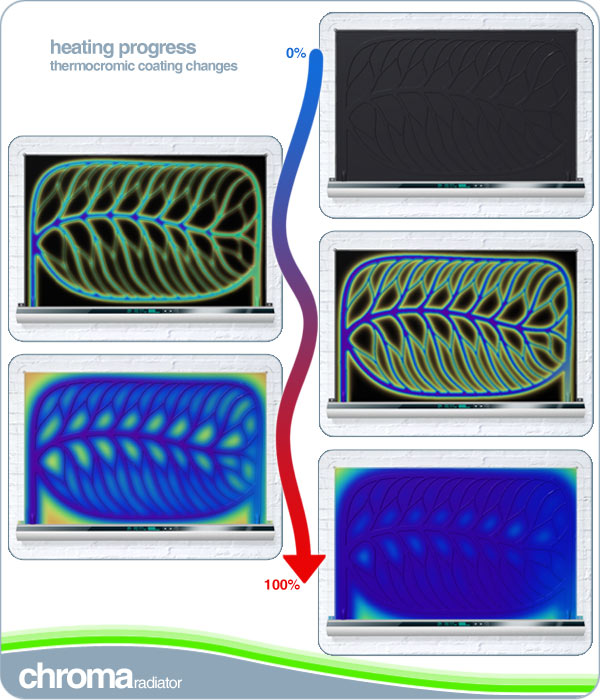

The functional surface has a thermocromic coating, used for example in safety, medical and retail applications. The radiator colour changes depending on the temperature, therefore, during heat process colour first emerges (the coating is black at room temperature), then it is changing according to a colour ramp, and finally the plate is mainly blue with slight hue variations. The colour ramp could be changed using other pigment.

Control and adjustment functions are performed by means of electrovalves, a thermocouple and a control circuit board that can be manage by an LCD display and a piezoelectric keyboard.

Chroma radiator

Heating progress

Heating progress

Explode view

Explode view