'Cascade' OLED Chandelier: Curved OLED Laminated Copper Elements by alexdelapole from uk

designer's own words:

Project Motives: Showcase unique potential of OLED technology.

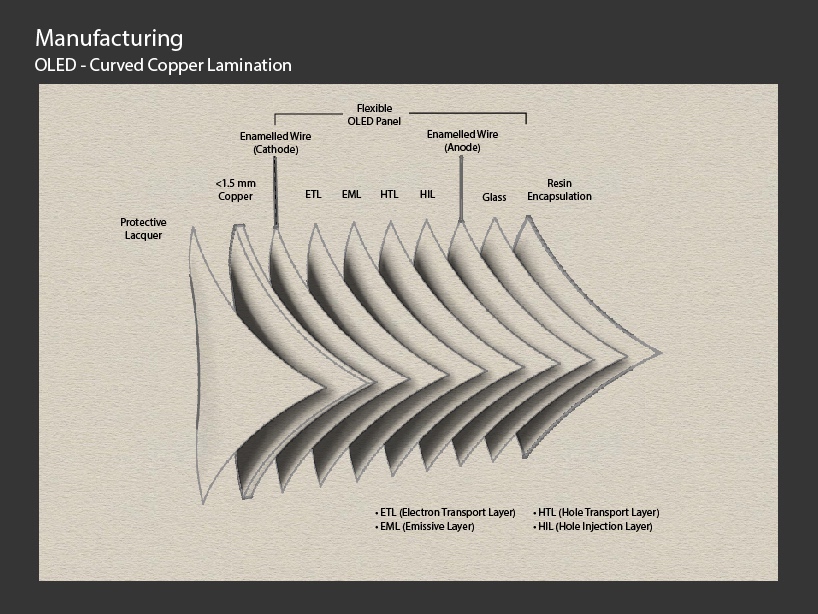

Only OLED technology makes this design possible. It relies on the flexible and thin emissive surface for lamination to curved copper plates.

Special Technical Notes:

- Enamelled wire is used for outer insulation whilst providing electrical conductivity to OLED panels. A clear coating retains aesthetic quality of the metallic surface. It is thin enough to enable rotational movement of curved panels.

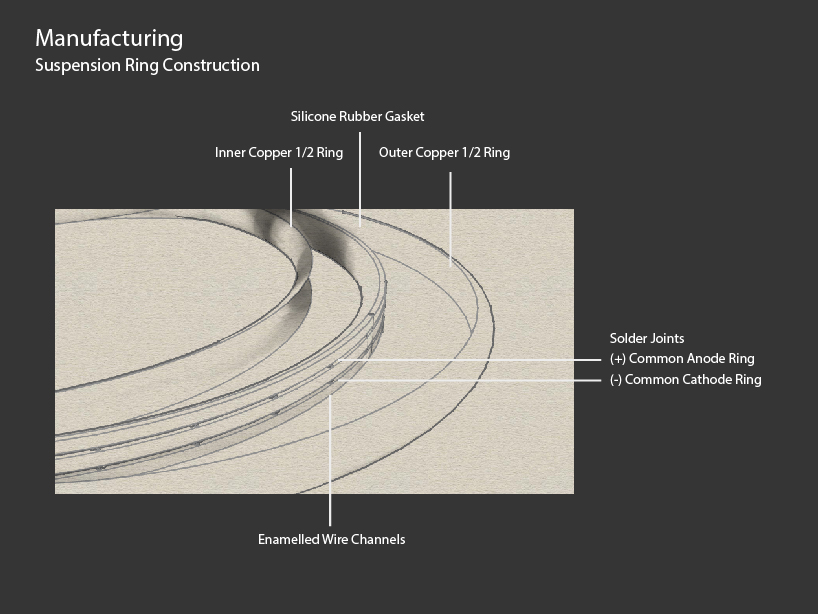

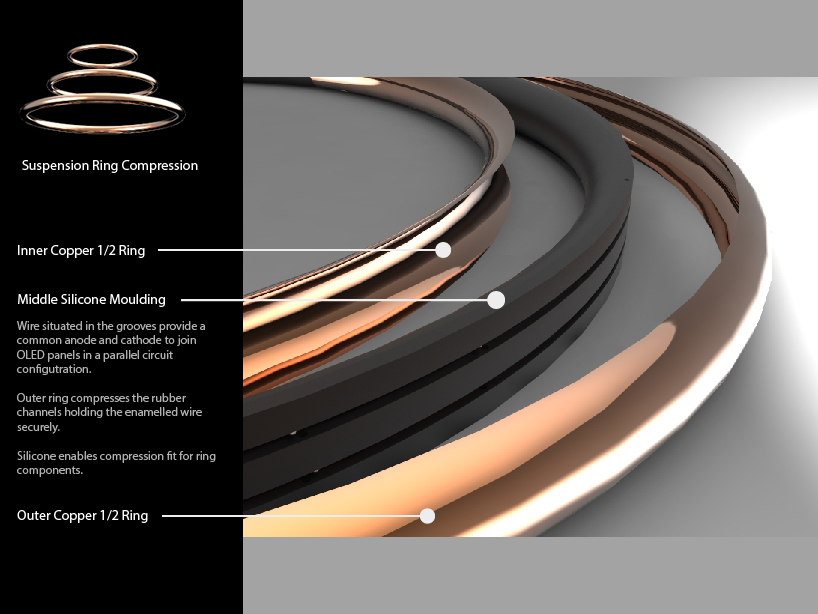

- Silicone rubber gasket: The flexibility of the silicone gasket enables the outer copper ring to push-fit securely in place. This reduces the requirement for additional fixings.

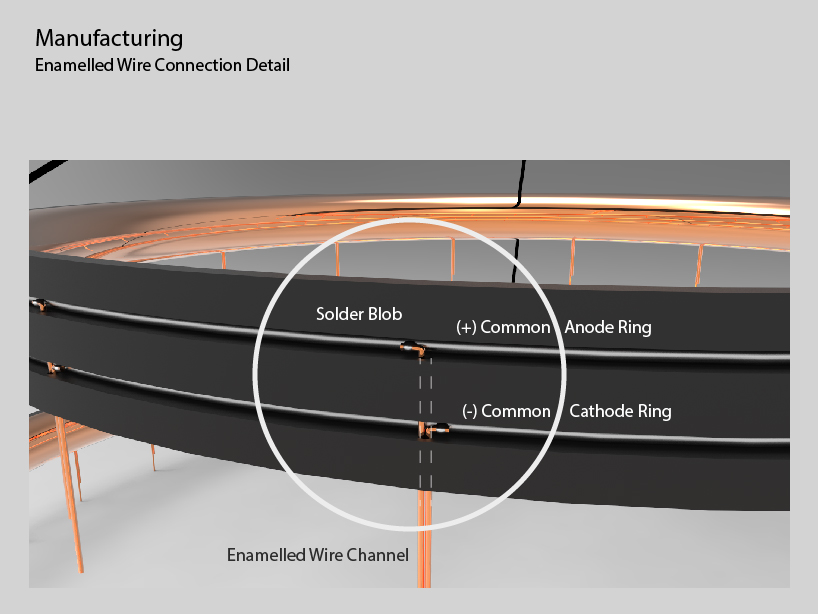

- Common anode and cathode rings join the OLED panels in a parallel circuit configuration.

- Assembled, the outer copper ring compresses the rubber channels where the enamelled wire is inserted.

The pendant-chandelier takes inspiration from North-American dreamcatchers - “You Dream, We Light”.

Manufacturing:

Automated pressing of copper sheet squares. Cutting enamelled wire to desired length. Soldering enamelled wire to anode and cathode contact points. Pushing outer copper suspension ring down to compress silicone rubber middle. Attaching (top) smallest ring contacts to mains DC transformer to be concealed inside ceiling.

Materials: Raw copper, polished for natural aesthetic beauty of material. Highly recyclable material for end-of-use nutrient cycle return.

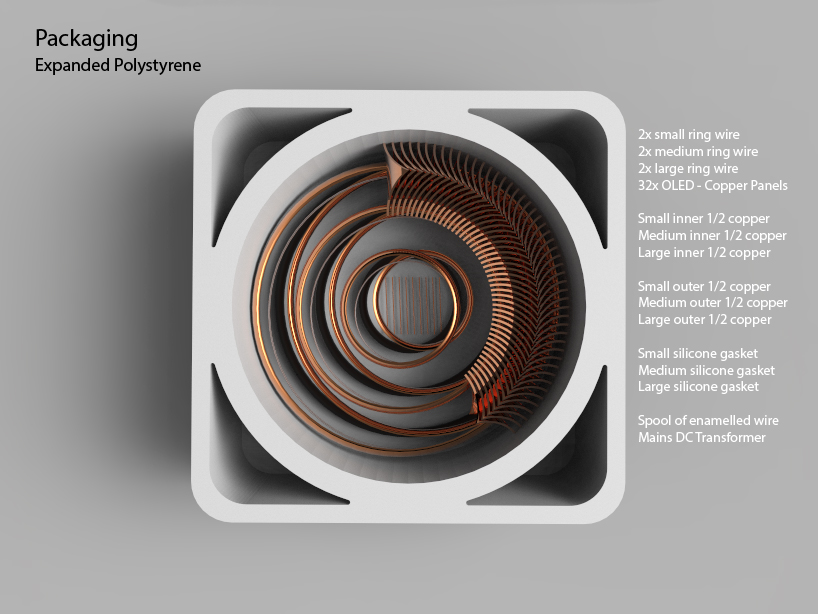

Expanded Polystyrene is suggested for safe packaging and transportation. The components are intended to be assembled in-house due to the delicate construction which may require a skilled worker.

Environment: Decorative light suitable for the home, bars, cafés, restaurants, office spaces, art galleries, reception areas.

Front cover render “You Dream, We Light”. Licensed image – Svetlana Vitkovskaya.

Suitable night or day. Licensed image – Nuttapol Yupothong.

Manufacturing Detail – Curved OLED copper lamination diagram.

Manufacturing Detail – Suspension Ring Construction.

Manufacturing Detail – Enamelled Wire Connections.

Assembly – Suspension Ring Compression.

Expanded Polystyrene Packaging.

Short description of the design’s unique selling points