ARIADNI DOOR HANDLE by andreas kyranis from greece

designer's own words:

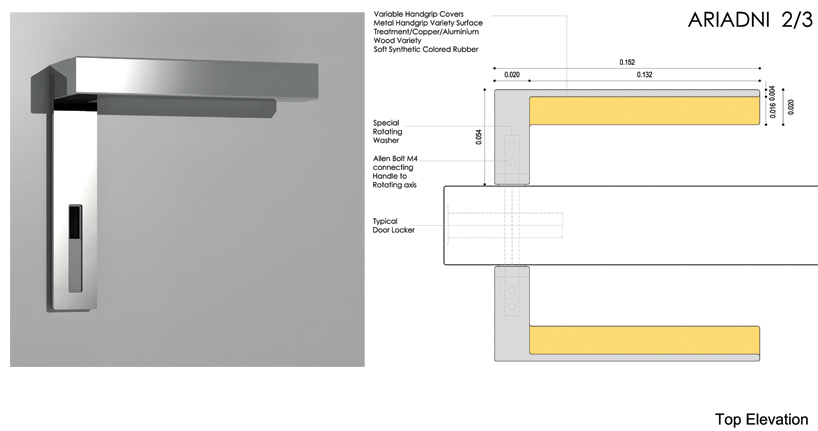

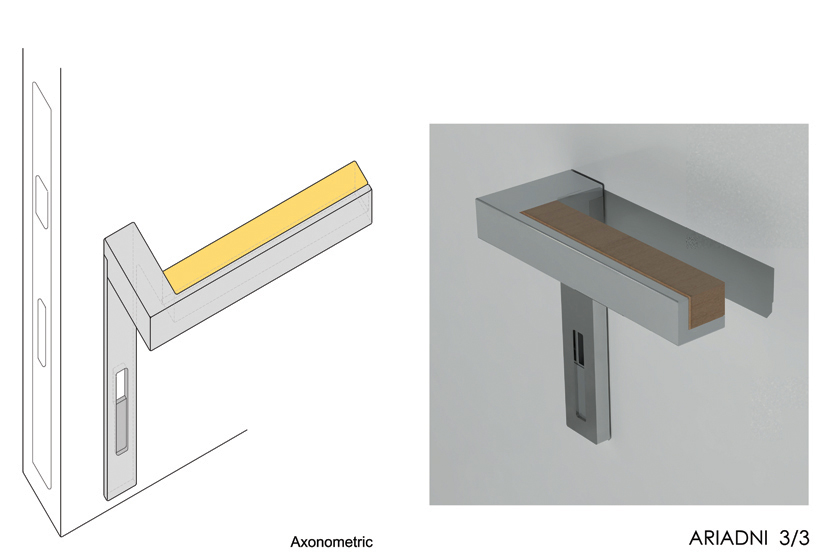

Similar logic to ETOLOS K, ARIADNI reveals the flexibility of developing a product system through the insertion of a different material surface. Possibility of developing multi-like transformations. The austirity of the design becomes playful with the coexistence of different materials, especially if products have different production technologies and philosophies. For example a combination of a glossy metal block with a coarse wood surface hand-made or artificially textured. The integration can also have the additional meaning of the alternative operator product iconography, which in turn may be industrial procedures, for example serigraphy with different painting gestures.

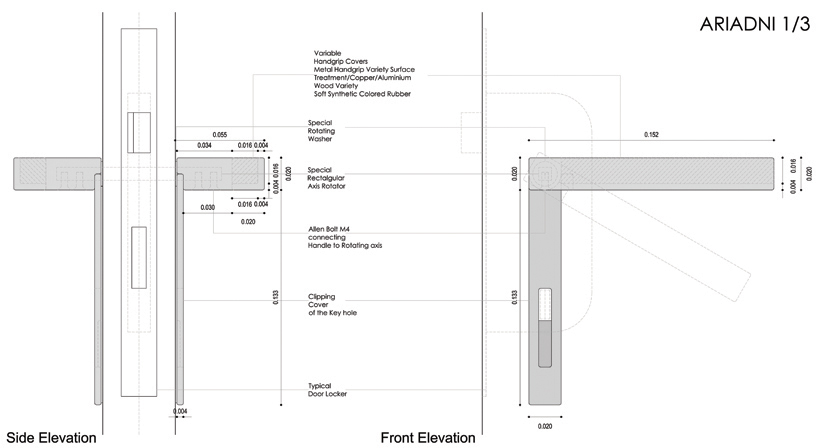

The designed product is a result of an unfolding that occurs in a rectangular net section sized 20x20 mm on the handle and a section 20x4mm on the clipped material. it is a proposal for a composition of a quorum of a door handle into a single abstract image. The rosette for the handle and a rossete for the lock disappears into the composition of the whole. The rotation movement axis and the key hole, result to a clean geometric distinctive sculptural interventions in the initial dominant geometry.

A door handle that has references to Early industrial production but to be produced requires Post industrial procedures.

Postindustrial utmost precision CNC machines

Simplicity /Purity /Frugality

The functional parts are trying to express themselves in a compositional totality

The whole product endowes gravity with far more than the minimum satisfactory

TECHNICAL DATA

Materials: stainless steel, aluminum, copper, zamak, inox, coarse wood, treated glass, synthetic materials

Texture: glossy or matte and different surface treatment

Finishes: edges with a radius of 0.5 to 1 mm, soft finishes that do not injure

Technology: the product could have been produced into the 19th century with mechanical engineering and handcrafted tools from a very good master of crafts with high cost

Production method: today probably the best way of producing the door handle it would be through the following stages:

Casting and molding of the basic quorum

Detailed machining on CNC milling

Polishing-finishing sander by robots

Final finishing procedures plating in succeeded bathrooms

It would be very interesting an inox version produced directly from machining processes

Treatment only in CNC milling machines and handmade mat polishing with only protection some very fine matte varnish

RESPECT WITH THE STANDARD ACCESSORIES MARKET

The products can be adapted to any common lock out in the market with the prefabrication of some special components:

Special square rotating pivot axis with the standard cross-section who will be able to host allen bolts and the possibility of related reduction and increase in response to the different door thicknesses. The apparent axis in the working parties will have the same surface treatment as the apparent remaining parts.

A special very thin rotation washer in connection with the door knob. If we are to function as spring-loaded handles on the market, it should be designed to fit into a recess within the thickness of the handle and be a part that is not available on the market according to our knowledge, ready at very small dimensions required by our design.

SIDE AND FRONT ELEVATION

TOP ELEVATION AND PHOTOREALISTIC VIEW

TOP ELEVATION AND PHOTOREALISTIC VIEW

AXONOMETRIC AND PHOTOREALISTIC VIEW

AXONOMETRIC AND PHOTOREALISTIC VIEW