Access Handle by mac low from usa

designer's own words:

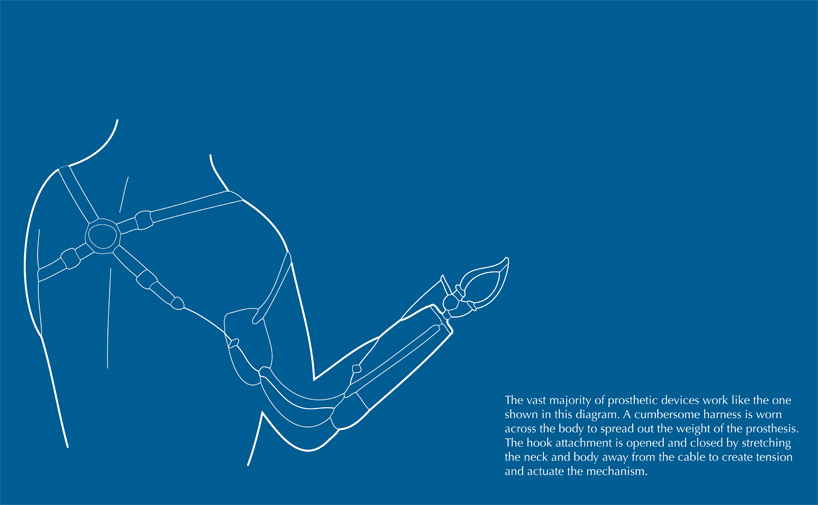

the access handle is designed to interface easily with both a normal hand as well as the most common type of prosthesis in use today. there are some truly amazing developments happening in the area of prosthetics. i have no doubt that one day everyone person who loses a limb will be fitted with a high-tech cybernetic implant. unfortunately that day will not come for many many years. the people we always see in the news testing these devices represent individual cases out of hundreds of thousands. the reality that nearly all 1.7 million americans who have lost an arm face - and millions more worldwide, is that they get up, strap on a cumbersome body harness and use a hook prothesis to meet their needs.

most people have seen this prosthesis at some point in their lives. but what most people don't know is that the hook is not opened and closed with the stump of the arm at all. when i started this project i thought that by flexing the muscles in the stump the hook opened and closed, when actually it is much more crude. a cable runs from the hook to a neck strap in the body harness that has to be tugged away from the hook to open it, and relaxed to close it. to get a feeling for how awkward this is, tape a dowel to your arm and tie a sharpie to the end of the dowel. now try and write your name. it's almost impossible.

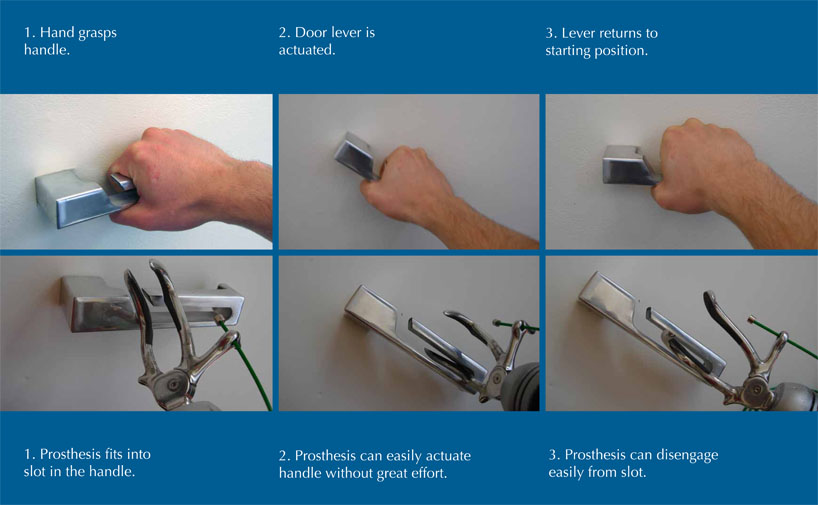

the slot cut into my door handle means that a hook prosthetic only needs to be opened a fraction of the distance to grip it, so the user does not have to strain as hard to open the hook. the handle is polished on the outer surfaces for the comfort of a normal hand, but is finished with a rough sandblast on the inside of the slot to provide more traction for a prosthetic - as well as a degree of auditory and tactile feedback from vibration when the prosthesis moves over it.

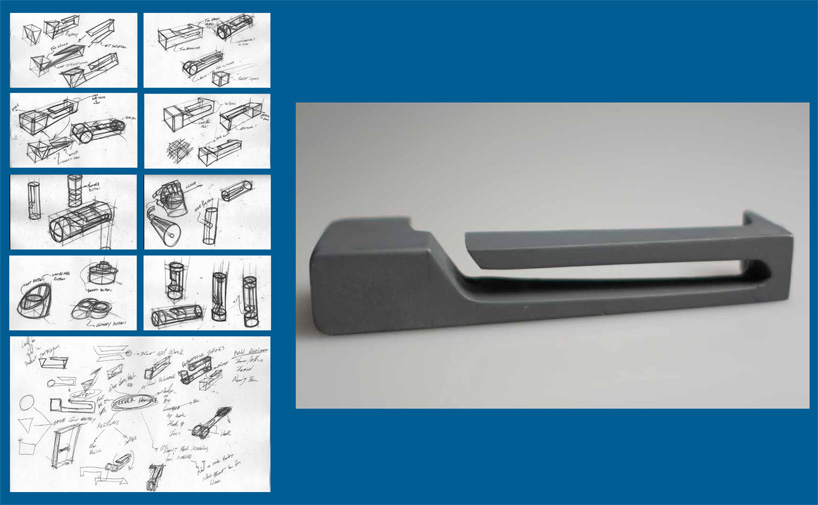

i created the form to be suitable for use both in a home or business and to fit with standard internal mechanisms. the handle shown was machined by hand on a good ol' bridgeport mill from a solid block of 5051 aluminum. it was polished by hand. in production it is designed to be either sand casted or injection molded.

the handle mounted

showing dual use

showing dual use

some images of inspiration

some images of inspiration

process of creation

process of creation

different views and angles

different views and angles

diagram of a normal prosthetic

diagram of a normal prosthetic