alex stchekine assembling shinola bikes. each bike is assembled by hand, one at a time, in the detroit workshopimage © designboom

you don’t know shit from shinola.founded in 1907, shinola, has been the brand name of a popular shoe polish product from the first half of the 20th century.of course, shinola wasn’t the only shoe shine out there, but the brand name might be one of the most memorable for the saying ‘you don’t know shit from shinola’.(so the story goes, during WWII a disgruntled young private decided to shine his general’s shoes one day with shit rather than shinola. the rumor spread along the front lines, and when the war ended, the legacy was imprinted on the american vernacular. so while shinola may have been a popular product, its name lived on not only because of shiny shoes, but because of … some dog shit. )

shinolaheath carr, principal of dallas-based bedrock manufacturing, was looking for a brand name that would be associated with ‘america’ – and that was instantly recognizable and adopted — ‘shinola’. carr is committed to contribute to a renaissance of american manufacturing, with an emphasis on craftsmanship and well designed products. by manufacturing (assembling) all of its products in the U.S., shinola unlike most companies operate in an unique way: products are released when they are ready, they are not restricted to retail seasons. shinola will unveil its collection ranging from watches and bikes to leather and paper goods in spring 2013.

designboom had an opportunity to see first hand the shinola production facilities.

RUNWELL

RUNWELL

designer sky yaeger, who has previously worked at bianchi and swobo, came on board in early 2011 to develop the first three models of classic lugged steel, internal gear hub city bikes, called RUNWELL and BIXBY (previously shinola shoe shine product names).the prototype frames were brazed in portland, oregon, by custom builders ira ryan and tony pereira, but the production the lightweight, comfortable steel frames (using true temper tubing) and forks are made by waterford precision cycles, founded in 1993 in wisconsin.wheels are built by sta-tru with DT swiss spokes and nipples. small parts like addles, tires, handlebars, cranks, rims, spokes, grips, pedals, kickstands, basketsthe decals, the chainstay plate and head badge are also sourced from the U.S., while the rest of the components come from asia (when it’s not possible to acquire certain parts domestically, it is only then that the company sources its materials from elsewhere).the bikes are designed and built specifically for urban riding, with a focus on functionality, durability, and aesthetics. the design is translated from the enduring french style of ‘porteur’ bicycles, the runwell delivers a classic blend of urban style and practicality. virtually maintenance free, courtesy of the high-end shimano alfine 11-speed internal hub, daily riders will never need to worry about adjustment,maintenance or exposure to rain and snow.

the biplane fork crown, the headbadge is embossed with the bicycle model nameimage © designboom

the biplane fork crown, the headbadge is embossed with the bicycle model nameimage © designboom

the BIXBY

the BIXBY

the cruiser bike BIXBY riffs off the fun look of the curved top tube, but improves on the fit and function with nimble frame geometry and a shimano3-speed internal hub. offered in both a classic men’s and women’s frame design, with thoughtful touches like gender-specific saddle design and proportional geometry. the bicycle assembly, which includes a bicycle designer and one assembly worker, will produce 2,000 bikes annually.

the BIXBY’s female version

the BIXBY’s female version

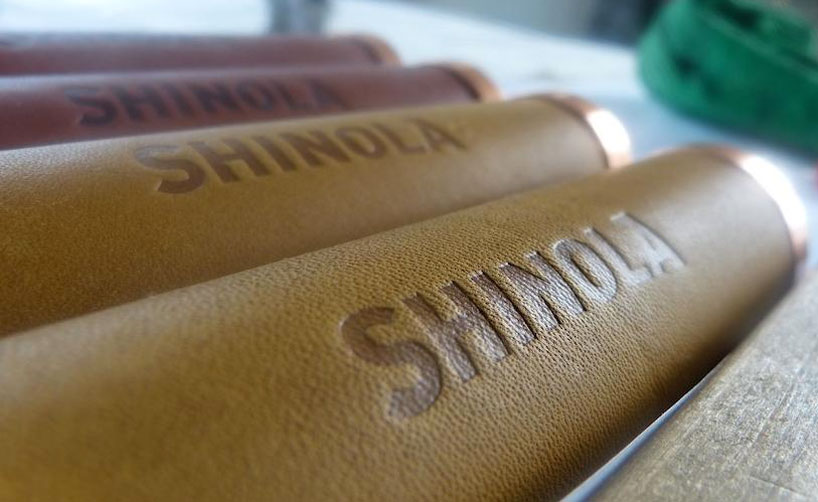

shinola leather grips

shinola leather grips

image © designboom

image © designboom

image © designboom

image © designboom

chainguards

chainguards

‘there are no factories dedicated to making complete bicycles in the USA. the well-known USA-based bicycle companies design their frames and components in the states, but virtually all their production has moved to asia. some of the eponymous, iconic names of the past live on, such as ‘schwinn’, ‘raleigh’ — all over 120 years old, but their frames are made in china and taiwan…’ creative director, daniel caudill explains to designboom.

the shinola headquartersimage © designboom

the shinola headquartersimage © designboom

the shinola headquarters is a cross between antiseptic intelligence agency and a post-industrial warehouse. the company has taken up residence inside the ‘argonite building’, built in 1928 across the street from the original GM headquarters, now operated by the college for creative studies. shinola is currently occupying half of the floor in the renamed ‘a. alfred taubman center for design education’. the 30,000 sq ft space is split between an office, bicycle assembly and watch factory.shinola’s engagement with CCS includes also educational projects involving student visions of a new bicycle design.

designboom’s editor-in-chief visiting shinola’s watch factory in a the pressurized room — to keep dust out.image © designboom

designboom’s editor-in-chief visiting shinola’s watch factory in a the pressurized room — to keep dust out.image © designboom

‘we knew we were always starting with watches and the other categories came pretty organically from there. the assortment will allow us to tell a better story at retail and online and the products all compliment each other. the whole idea is to create products that are somewhat evergreen, it’s really about stripping it down to its bare essentials and, whatever it is, making it with the best materials and the absolute best construction. this is the redefinition of luxury — a sensible realization that a brand name is worth nothing beyond the quality of the product it’s printed on, and a deep-seated belief that products should be built to last a lifetime, and they should be built right here in america.’ says daniel caudill of shinola.

distribution will be through specialty stores and online as well as shinola’s own shops (currently shinola is working on two stores in detroit and tribeca/manhattan.

the shinola argonite 1069

the shinola argonite 1069

this february 2013, the shinola argonite 1069 watches will be available for pre-order!

each movement is hand-assembled in a dust-free cleanroom-like environment, and tested throughout the process to ensure years of accurate performance. the factory is built with a manufacturing capacity of 500,000 watches a year. the watchmaking logistics were handled by ronda AG, a family operation that’s one of the last independent swiss movement manufacturers in the world. after a year of work, the movement factory lines are in place and the team is hand-assembling the movement — the argonite 1069. soon they will be assembling the entire watch here, using high-quality horween leather watchstraps produced by the renowned florida-based company, hadley-roma.

the watch assemblyimage © designboom

the watch assemblyimage © designboom

the watch assembly has 20 employees and will produce 45,000 watches this year. the detroit-based workers carefully assemble products by hand, one piece at a time: 46 custom-made pieces that comprise the watch movements.the completed movements, one roughly the size of a dime and the other a quarter, contain parts that are so small they are assembled using tweezers, vacuum styluses and micro screwdrivers.

te’nesha martin, line assembly specialistimage © designboom

te’nesha martin, line assembly specialistimage © designboom

the person putting the movement together must sit within inches of the machine and, at times, use an eye loupe to ensure that even the smallest parts are properly installed. there is also an electronic module, which contains the chip and the quartz crystal that drives the mechanical parts.

image © designboom

image © designboom

the coil, made of an ultra-thin copper wire wound around a magnetically conductive core, creates the magnetic field that drives the watch motor. one essential part of that motor is the ‘rotor’, a tiny magnet that reacts to the changes in magnetic field by spinning on its axle and engaging theother wheels all the way down to the ones that carry the hour, the minute, and the second hands of the watch.

image © designboom

image © designboom

image © designboom

image © designboom

the jewels on the gold-plated train wheel bridge have to be precisely oiled to ensure the least amount of friction between fixed and rotating parts. once added to the assembly, the electronic module has to be tested on a special computer, not only to ensure that the integration betweenelectrical and mechanical components is done correctly, but also for time accuracy. the calendar parts are then added and tested; a dummyhand is set to check for proper operation of the finished movements.

fifty movement pieces sit on a tray after being hand built by workers at shinolaimage © designboom

fifty movement pieces sit on a tray after being hand built by workers at shinolaimage © designboom

setting the dial and the hands, assembling the resulting ‘fit-up’ into the case, adding the crown, closing the case back or crystal, and then adding the straps also have exacting standards and are performed with a high degree of precision as well.

technician don schulzimage © designboom

technician don schulzimage © designboom

master watchmaker stefan mihocimage © designboom

master watchmaker stefan mihocimage © designboom

clean desks at end of the dayimage © designboom

clean desks at end of the dayimage © designboom

images from shinola’s collaboration with the CCS center of creative studiesimage © designboom

images from shinola’s collaboration with the CCS center of creative studiesimage © designboom

happening now! thomas haarmann expands the curatio space at maison&objet 2026, presenting a unique showcase of collectible design.