a few days ago, designboom visited NIKE‘S small and exclusive italian factory. the facility specializes solely in the production of the brand’s top-of-the-line, professional athletic boots and is located in montebelluna just forty minutes from the city of venice in the countryside for nike’s newest and lightest football boot, the NIKE GS (or green speed). we’re happy to offer our readers images and a video of the making process.

the materials which comprise each shoe made in the small factoryimage © designboom

the materials which comprise each shoe made in the small factoryimage © designboom

nike was founded in 1964 in beaverton, oregon, USA, under the name ‘blue ribbon sports’ by bill bowerman and phil knight as a sportsware and equipment manufacturing company. today nike, inc. is the world’s largest, most recognizable and most profitable organizations in the filed of sports business. though the corporations’ roots are in the united states, their factories and niketown stores are found all over the globe.

nike’s selection of this particular location for their manufacturing plant is no coincidence. the region is known for its rich history of artisan shoe construction in italy– a country world renowned for their skill in the production of artisan footwear. within this cozy italian factory, an innovation team, product development team and production group, comprised of 15 individuals with a collective experience of 350 years in footwear, were able to build the nike GS. our behind-the-scenes look at nike’s production facility pictures the efforts made by nike’s team of creatives to develop the lightest and most minimal shoe available form their brand, observing the construction of their sustainable soccer shoe from start to finish.

the traction plate of the boot is crafted from a mix of material including 50% castor beans and 50% plastic where the sock liner is made from 100% castor beans. the laces, tongue and lining of the nike gs, are formed from a minimum of 70% recycled materials while the collar and toeboard have a material makeup including least 15% recycled matter. the concept boot is not formed from 100% recycled matter and energy, yet it is the first wide-reaching production demonstration by nike of the potential for sustainable or low-impact design in the development of high-performance football boots.

segments of the shoe in varied states of constructionimage © designboom

segments of the shoe in varied states of constructionimage © designboom

individual components of the shoeimage © designboom

individual components of the shoeimage © designboom

designboom’s nike greenspeed factory visitvideo © designboom

moulding the upper over the toe boardimage © designboom

moulding the upper over the toe boardimage © designboom

pulling the toe and upper into formimage © designboom

pulling the toe and upper into formimage © designboom

resting for a moment as the form fits the shape of the mouldimage © designboom

resting for a moment as the form fits the shape of the mouldimage © designboom

the completed bootimage © designboom

the completed bootimage © designboom

each shoe is outfitted with the flag of the country that wears the bootimage © designboom

each shoe is outfitted with the flag of the country that wears the bootimage © designboom

the nike GSimage © designboom

the nike GSimage © designboom

the underside of nike’s newest bootimage © designboom

the underside of nike’s newest bootimage © designboom

the boot ready for packagingimage © designboom

the boot ready for packagingimage © designboom

graphic breakdown of the boot’s componentsimage © designboom

graphic breakdown of the boot’s componentsimage © designboom

‘green’ aspects of the nike GS green speed:-quarter/tongue – 95% recycled material-reinforcement – 20% renewable material-collar – 15% renewable + 32% recycled polyester-lining – 88% recycled polyester / 12% pu. solvent free-laces – 70% recycled polyester-foam – soy based, made of 15% palm oil, a renewable resource-toe board –17% recycled material and all waste is re-used to create a closed loop product-tongue- made of 95% recycled material

a view of the nike GS signage within the small factoryimage © designboom

a view of the nike GS signage within the small factoryimage © designboom

the station where rubber cement is applied to the bootimage © designboom

the station where rubber cement is applied to the bootimage © designboom

an additional view of the italian nike production facilityimage © designboom

an additional view of the italian nike production facilityimage © designboom

boot-shapers and half completed shoes wait on a shelving systemimage © designboom

boot-shapers and half completed shoes wait on a shelving systemimage © designboom

nike’s montebelluna factoryimage © designboom

nike’s montebelluna factoryimage © designboom

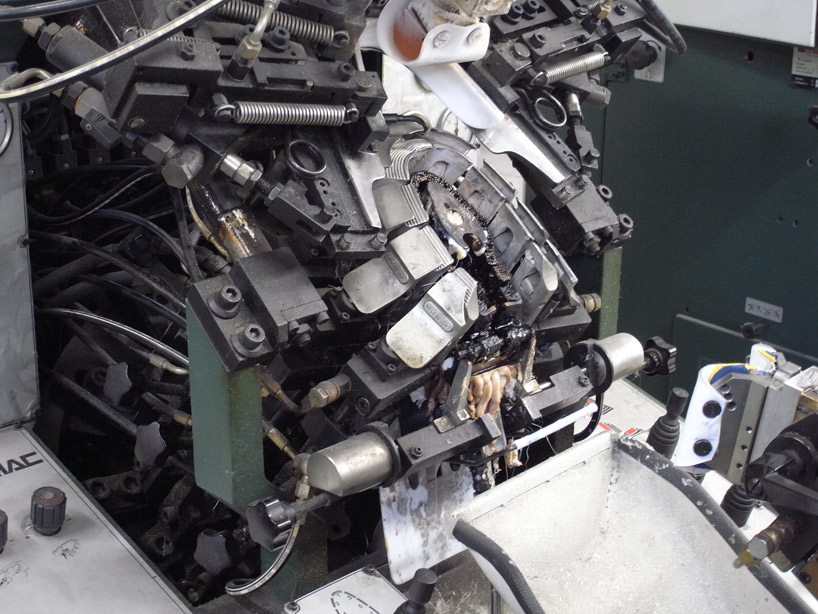

detailed perspective of a machine in the manufacturing line for the nike GS bootimage © designboom

detailed perspective of a machine in the manufacturing line for the nike GS bootimage © designboom

moulds for the soul of several nike football shoesimage © designboom

moulds for the soul of several nike football shoesimage © designboom

each of the baskets contain a collection of differing plastic components in which each shoe takes its size and general shapeimage © designboom

each of the baskets contain a collection of differing plastic components in which each shoe takes its size and general shapeimage © designboom

another perspective picturing the production facilityimage © designboom

another perspective picturing the production facilityimage © designboom

nike GS is produced in such a way that the design has considered both lowe nvironmental impact in combination with heightened performance engineering for what is UK-born, US-based designer andy caine and nike’s lightest, fastest, and lowest environmental impact production boot for the company to date. the specialized italian production facility employs renewable energy for the construction of the shoe which featuring recycled and renewable materials throughout its design.

industrial sewing machine which embroiders a custom logo, name and country flag onto each shoeimage © designboom

industrial sewing machine which embroiders a custom logo, name and country flag onto each shoeimage © designboom

boots packaged and labeled according to the player- display of the boots which nike has created image © designboom

boots packaged and labeled according to the player- display of the boots which nike has created image © designboom

several of the high-powered production pieces required to build each of nike’s football bootsimage © designboom

several of the high-powered production pieces required to build each of nike’s football bootsimage © designboom

the cozyplant features a level of personalization in the manufacturing line, as many of the machines are decorated with sport or nike related photographsimage © designboom

the cozyplant features a level of personalization in the manufacturing line, as many of the machines are decorated with sport or nike related photographsimage © designboom

image © designboom

image © designboom

image © designboom

image © designboom

image © designboom

image © designboom

a workstation for precise additions to each piece of footwearimage © designboom

a workstation for precise additions to each piece of footwearimage © designboom

workers who produce the top-quality boots by nike are incredibly attentive while directing these powerful pieces of equipment image © designboom

workers who produce the top-quality boots by nike are incredibly attentive while directing these powerful pieces of equipment image © designboom

showcase of boot’s nike produces in the factory’s lobbyimage © designboom

showcase of boot’s nike produces in the factory’s lobbyimage © designboom

the nike symbol stands as the only indication to the hidden artisan football boot factoryimage © designboom

the nike symbol stands as the only indication to the hidden artisan football boot factoryimage © designboom