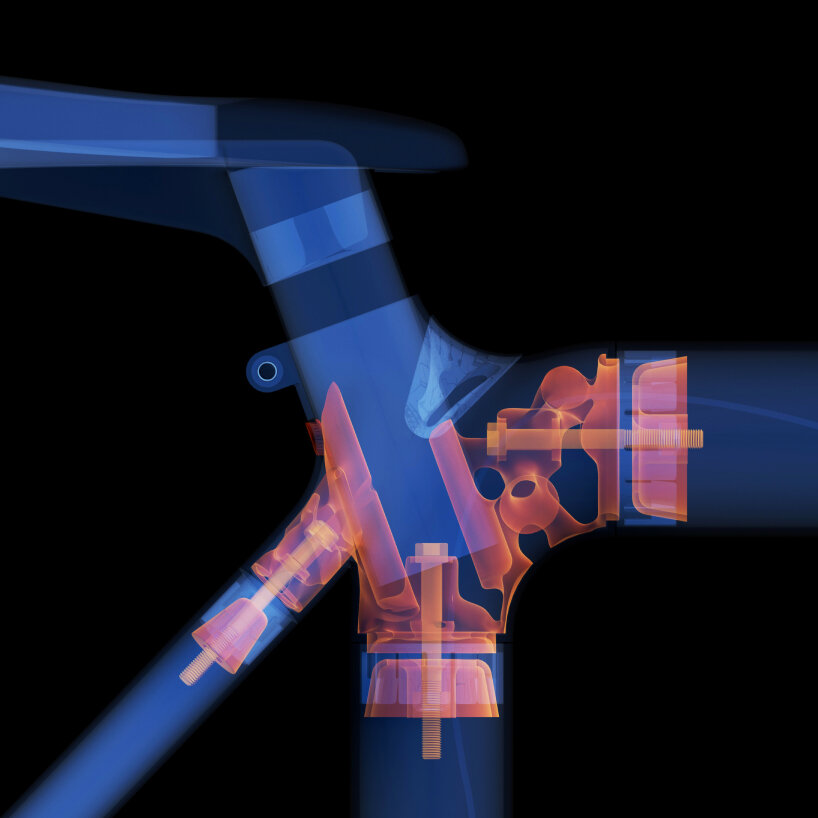

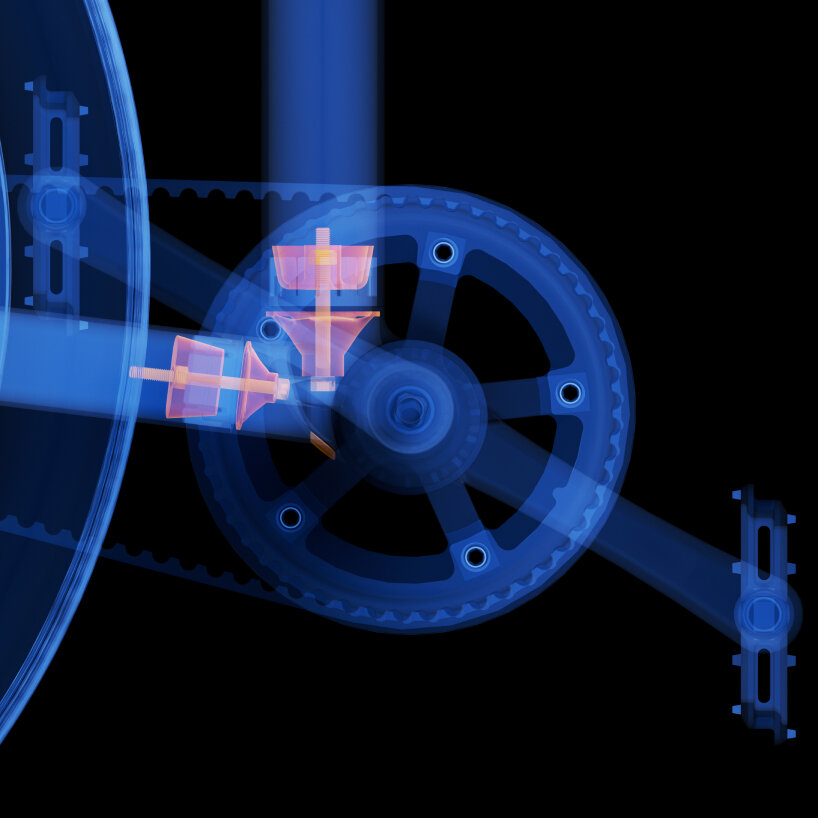

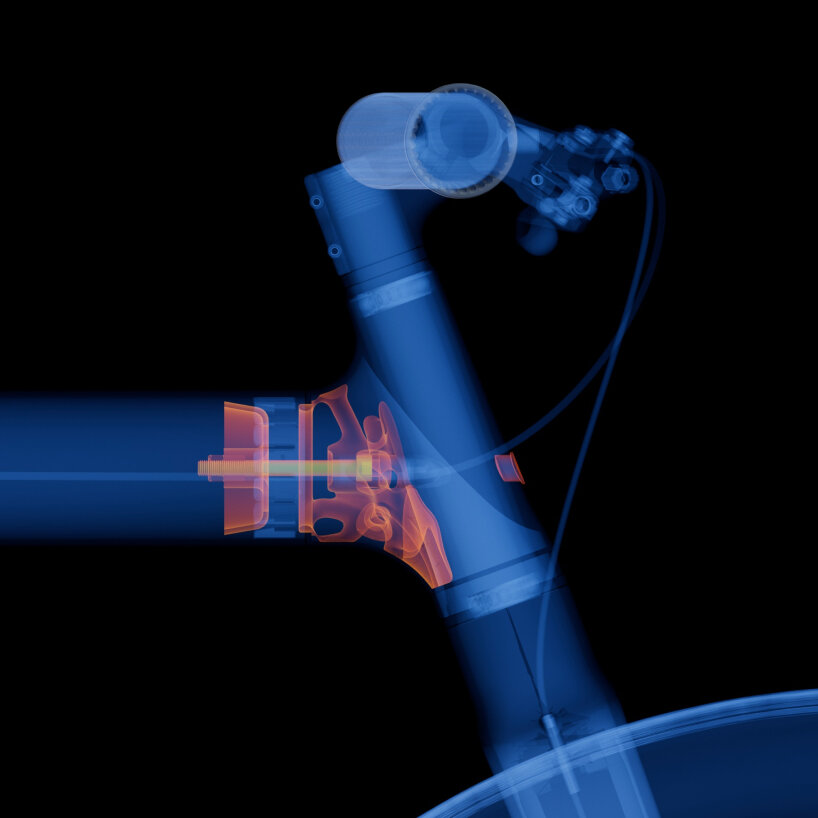

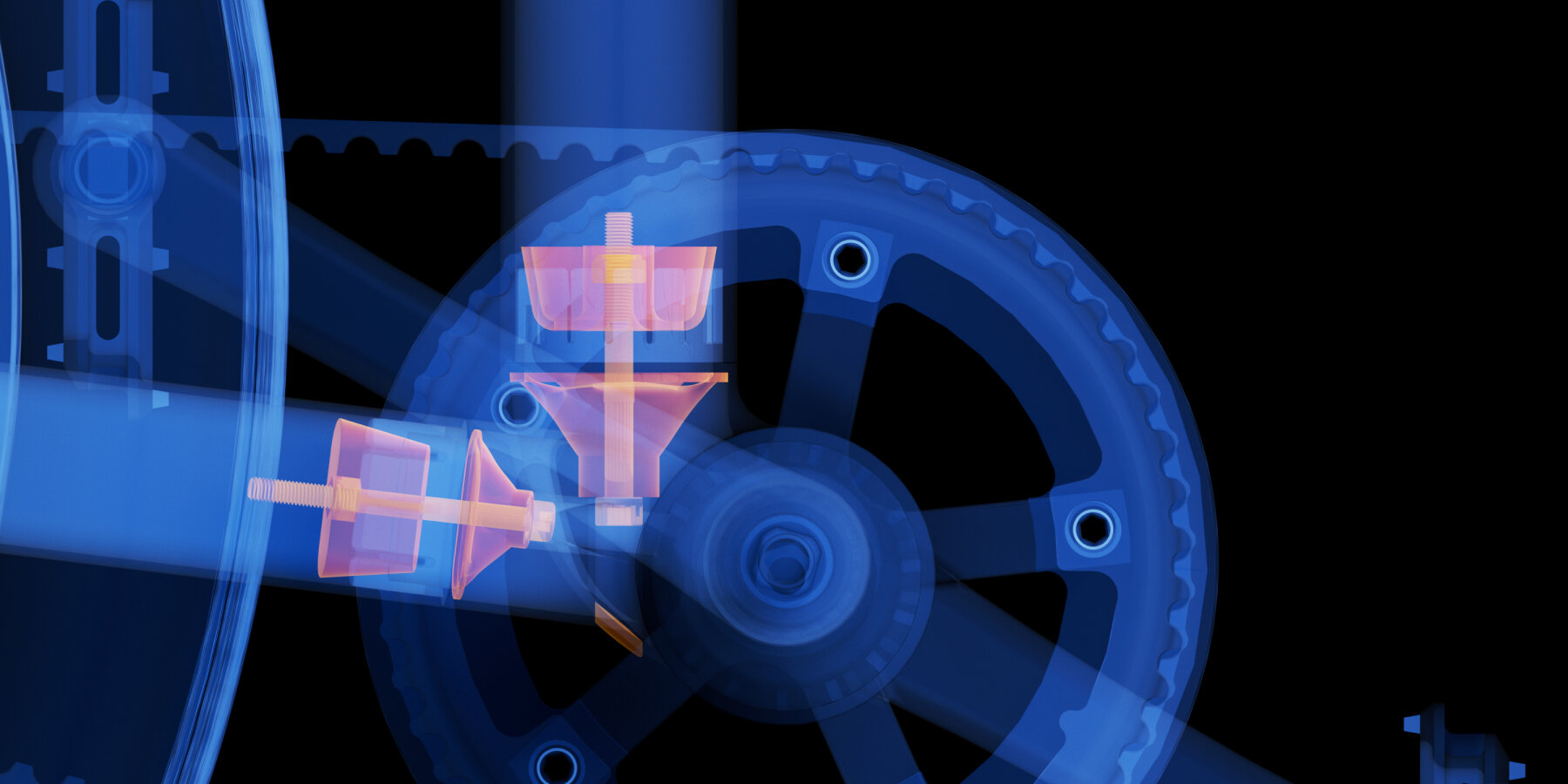

Alyx bike combines functional elegance with technological innovation in bicycle design

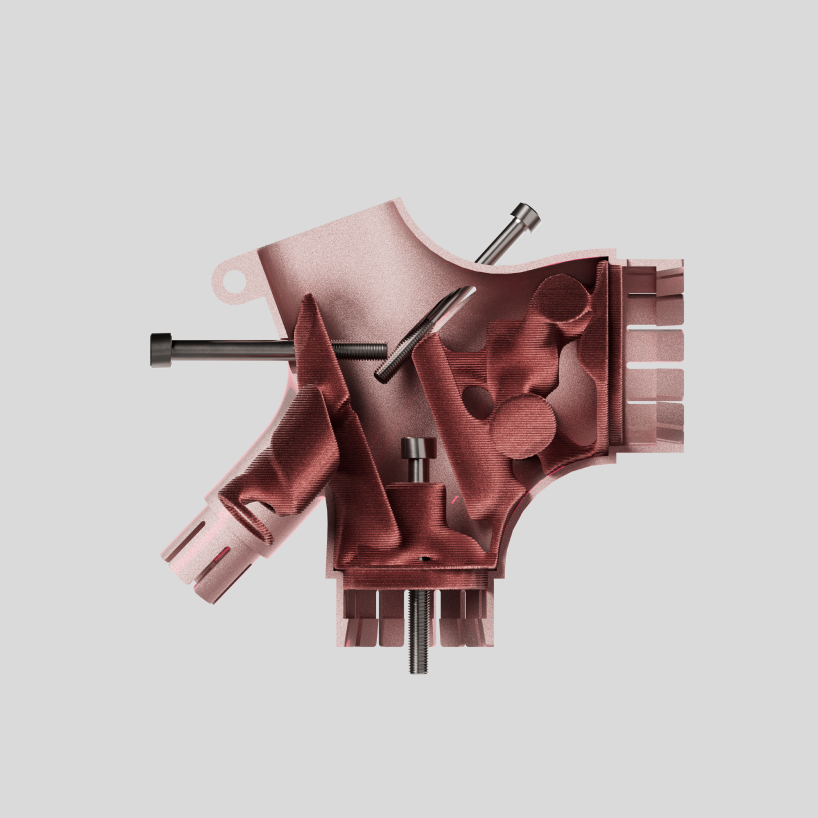

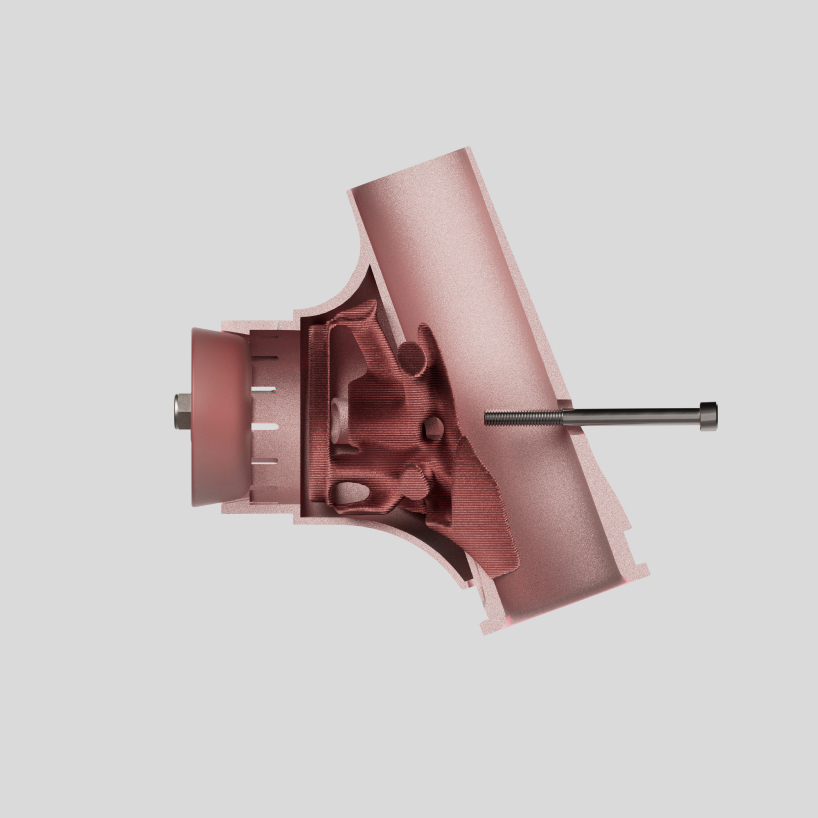

X-ray metal 3D printing

KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

happening now! thomas haarmann expands the curatio space at maison&objet 2026, presenting a unique showcase of collectible design.

each chair reflects an individual child’s input and imagination.

connections: +910

the spiral structure follows principles of fluid dynamics and thermodynamics to optimize heat distribution.

connections: 94

from 3D printed coral reefs to eggshell composite butterfly nests, designboom looks back at the top 10 social impact stories that defined 2025.

connections: 23

amid the rush of a hyper-accelerated world, the hue stands in for a blank canvas.

connections: 45