LAUFEN factory visit: glazing, firing, and testing image © designboom

this june, designboom requested a manufacturing tour of LAUFEN ceramics factory. we had the opportunity to document the many steps and design considerations that go into the production of bathroom fittings, offering a better understanding of the different design criteria and production methods required for these everyday household pieces, as well as the way in which such an ancient material as ceramic is being utilized in high-tech and industrial applications in the present day.

in our last article, we took you to the production floor of the factory, where craftsmen use the two techniques of plaster and pressure casting to produce the clay forms of every LAUFEN product. when we last left these pieces, they had just been dried to the point where they contain less than 1% of water, an important step to avoid pieces exploding in the kiln as the water inside evaporates into trapped bubbles of water vapor.

a fully automatic assembly line used for 97% of LAUFEN products transports casts to be sponged and prepped for glazing by human craftsmen, then glazed by robots, and then stored before kiln firing images © designboom

a fully automatic assembly line used for 97% of LAUFEN products transports casts to be sponged and prepped for glazing by human craftsmen, then glazed by robots, and then stored before kiln firing images © designboom

now the pieces are ready for glazing, the last step before kiln firing and then quality control. on automated assembly lines, pieces enter one by one into small workspaces. craftsmen meticulously dust and sponge each, ensuring that it is perfectly smooth and ready for glazing. a built-in camera in the workstation identifies the product, placing on a small screen a visualization of the orientation in which it must be placed in preparation for the glazing robot.

a LAUFEN craftsman prepares a product for glazing, carefully dusting and sponging the surface image © designboom

a LAUFEN craftsman prepares a product for glazing, carefully dusting and sponging the surface image © designboom

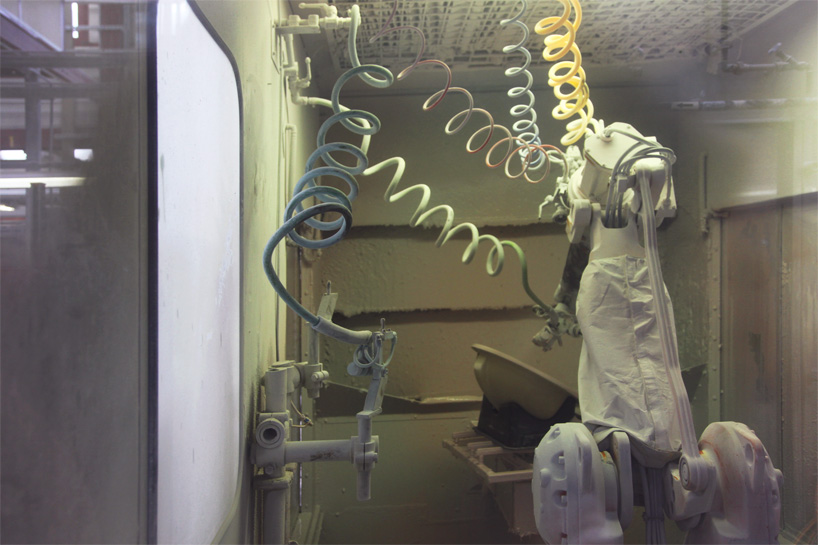

after the pieces are prepped for finishing, three large robots working in glass chambers evenly spray the product, based on a program specific to each model.

a robot evenly glazes a washbasin image © designboom

a robot evenly glazes a washbasin image © designboom

freshly glazed products coming out of the glazing station image © designboom

freshly glazed products coming out of the glazing station image © designboom

hand-applying glaze and applying the LAUFEN logo, in projects either too large or too recently designed to yet use the automated production line image © designboom

hand-applying glaze and applying the LAUFEN logo, in projects either too large or too recently designed to yet use the automated production line image © designboom

by contrast, large pieces continue to be glazed by hand in small workshop stands, each fitting about three small pieces and backed with a storage rack for both incoming and finished products. as in the automated line, workers dust and sponge products, before applying a coat of glaze by spray. the last step involves applying the LAUFEN logo.

the hand process is used for large pieces that will not fit on LAUFEN’s production lines, as well as for new products for which there is not yet a program to command the robot how to glaze.

upholding high hygiene standards for their products, LAUFEN completely glazes even the interior of pieces; above, a machine fills a toilet bowl with liquid glaze, in order to coat its interior image © designboom

upholding high hygiene standards for their products, LAUFEN completely glazes even the interior of pieces; above, a machine fills a toilet bowl with liquid glaze, in order to coat its interior image © designboom

LAUFEN is unique among bathroom producers in its emphasis on full glazing of pieces. the highly hygienic strategy ensures that over the full lifespan of a product, the finish remains full throughout, and no material negatively affects the ceramic or its cleanliness.

for ‘closed’ structures like toilets, a dedicated machine in the LAUFEN factory fills the entire product with liquid glaze, whose depth is monitored via a red laser point light. once full, the machine drains out the excess.

the red laser point on the toilet indicates the depth of the glaze, so technicians know when it is full and needs to be overturned to drain image © designboom

the red laser point on the toilet indicates the depth of the glaze, so technicians know when it is full and needs to be overturned to drain image © designboom

LAUFEN occasionally makes coloured pieces, but in recent years works foremost in white. nonetheless, glazes appear when wet to have a pink or blue tint, although this hue disappears after firing image © designboom

LAUFEN occasionally makes coloured pieces, but in recent years works foremost in white. nonetheless, glazes appear when wet to have a pink or blue tint, although this hue disappears after firing image © designboom

glazed pieces in temporary storage in the factory image © designboom

glazed pieces in temporary storage in the factory image © designboom

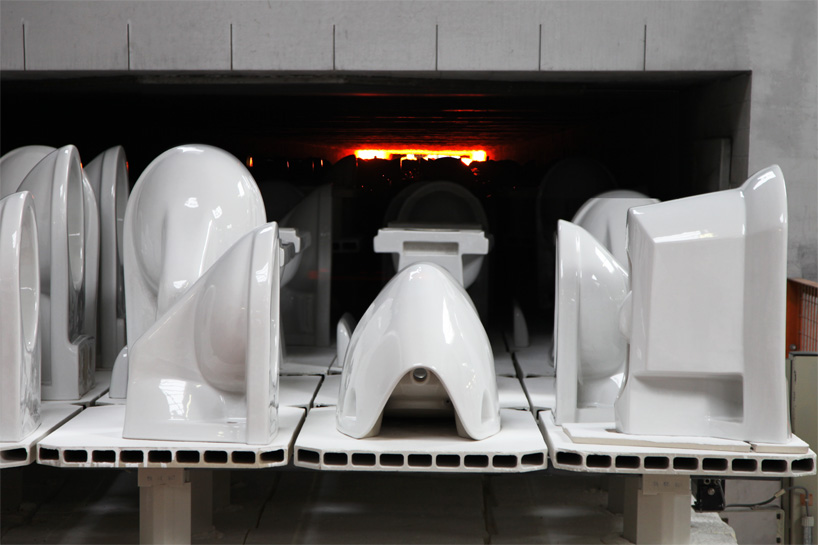

whether glazed by hand or robot, each piece is now ready to be fired, at an incredible 1250°C (2282°F). LAUFEN’s natural gas kiln is 104 meters long by 2.85 meters wide, at a height of 0.8 meters (341 x 9.4 x 2.6 feet LWH). because of the extreme heat, and the time required for it to completely warm up to the proper temperature, the kiln runs 24 hours a day, 7 days a week, besides a few days each year that are reserved for cleaning and repairing. this energy is far from lost, however, as LAUFEN recuperates waste heat from the kiln and uses it to power the kiln pre-heater and the company’s hot water systems.

the LAUFEN tunnel kiln measures 104 meters (341 feet) long, and takes about 26 hours for a product to pass through completely image © designboom

the LAUFEN tunnel kiln measures 104 meters (341 feet) long, and takes about 26 hours for a product to pass through completely image © designboom

moreover, the LAUFEN factory is open only five days a week, but products are moved in and out of the kiln during all seven thanks to an automated assembly line system at the switzerland plant. after glazing, the pieces are transferred in groups of 20 – 25 on a deck to a caged ‘buffer’ storage facility, where they are stacked in ‘carpets’: decks composed of 10 of these product-laden plates. a crane places the complete unit in storage, and when ready, a transfer car transports it to the pre-dryer and then kiln.

the cars of the kiln, loadable with the 10-piece decks (and thus each containing about 200 to 250 pieces), are lined with easily heated stone and covered by ceramic fiber mats. this lining, in conjunction with the use of plates along the sides of the kiln, prevents hot air from escaping into the bottom of the firing unit.

pieces entering the kiln image © designboom

pieces entering the kiln image © designboom

‘when we work with ceramics, the piece gets smaller during the production process because of the water that is inside. from the moment we take the piece out of the mold until it is dry, the piece gets smaller by about 3%, and during the firing process by about 8%. so the final product reduces its size by about 11%. this of course means that we have a lot of deformation which needs to be built into the product from the beginning, so that at the end it turns out to have a straight surface. for our development department, for our modelers, this is a very important aspect that they have to calculate this deformation and take all this in account when designing a new piece.‘ – LAUFEN plant manager simon imhof

these pieces demonstrate the importance of accounting for deformation when designing new LAUFEN products; all prototypes are carefully examined, and any necessary adjustments noted, before the design returns to the drawing board for changes image © designboom

these pieces demonstrate the importance of accounting for deformation when designing new LAUFEN products; all prototypes are carefully examined, and any necessary adjustments noted, before the design returns to the drawing board for changes image © designboom

view of the factory from the exit side of the kiln; finished products are being unloaded in the center aisle image © designboom

view of the factory from the exit side of the kiln; finished products are being unloaded in the center aisle image © designboom

the blue pipes running alongside the kiln are the burners image © designboom

the blue pipes running alongside the kiln are the burners image © designboom

pieces take about 26 hours to ride on their cars through the kiln. they warm gradually as they move closer to the center, and then cool slowly as they exit. the firing zone is a length of 57 meters (187ft), composed of 84 burners and split into seven control zones. next, a 9-meter (29.5ft) rapid cooling zone uses hall air to quickly cool the pieces from 1250°C to 650°C (1202°F, a difference of about 1112°F). over the next 36 meters (118ft), the products are cooled slowly to a temperature of 40°C (104°F), after which point they can safely enter and readjust to ambient air.

finished products exiting the kiln image © designboom

finished products exiting the kiln image © designboom

firing process video © designboom

after their journey through the pre-kiln and kiln, the fired products– still on their large decks– are collected by the automatic transfer car and brought to the dismantling station, a process that happens every 25 minutes. here the products are sorted, and the car retrieves a new, unfired set of products.

the recently fired pieces, however, are just beginning another important stage of the LAUFEN production process: inspection.

finished glazed products, awaiting quality control image © designboom

finished glazed products, awaiting quality control image © designboom

at LAUFEN, each piece is individually checked by a human craftsman. its surface is scoured for even the slightest imperfection — a dark mark (often a result of iron in the slip material), a small bump, or a surface scratch. it is then measured for the proper dimensions, both internally and externally. products that pass these visual controls are subjected to a vacuum test, a way of determining the existence of internal cracks. the piece is placed on a special table, all its external holes are sealed, and the air inside is sucked out with a strong vacuum. if the vacuum seal holds for at least 10 seconds, the piece has successfully passed the examination.

as in the casting and glazing areas, the unique bar code of each piece helps in reading and documenting its test results at various stages.

a LAUFEN inspection station image © designboom

a LAUFEN inspection station image © designboom

at this point, the pieces can be sorted. trading quality (TQ) products that meet LAUFEN’s strict standards are registered in the company’s inventory system, packed, and stored or transported to a retail location.

images © designboom

images © designboom

‘only 70-75% of the fired pieces are good,’ factory manager simon imhof explains. ’20-25% have small defects: these will go to the re-firing process. the small defect gets drilled away; we make a hole; we fill it again with glaze, and then we fire it again. this of course means extra costs for every piece that needs to be re-fired. but because it is ceramics and you work with natural raw materials, you cannot prevent getting some small defects.’

the re-fired pieces enter into a separate kiln, which is only turned on when it is filled to its capacity of about 600 pieces. this unit reaches the slightly lower temperature of 1200°C (2192°F), and takes a similar length of time for pieces to pass through: about 18 – 22 hours. but in this ‘shuttle kiln’, it is important that the products are permitted to very slowly reach the full temperature. ‘when the piece is still raw, you can fire it up relatively quick,’ imhof elaborates, ‘because the body is not that dense at that moment. but when you re-fire the objects, they have lot of tension; and when you fire them too quickly, they can easily get cracks.’ after re-firing, the pieces are subject to inspection and sorting.

at any stage of the firing processes, even broken pieces, which imhof notes represents around 5% of the total production, can be remilled and used again in the raw slip.

inspection station video © designboom  products set up for technical testing image © designboom

products set up for technical testing image © designboom

although LAUFEN’s cultural history is deeply rooted in ceramic, the company places an equal emphasis on the technical quality of its products. the company’s quality assurance department accomplishes two functions: the taking of random samples from the production area for testing, and ‘incoming control’, verifying the technical controls and functionality of new LAUFEN designs.

urinals in particular contain many internal electronic parts for automatic flushing, all built in-house at LAUFEN, and must resist the heavy wear of routine public use, so every piece is flush-tested to ensure its proper functioning.

‘antero’ the LAUFEN urinal presented at milan design week 2012, undergoes testing at the factory image © designboom

‘antero’ the LAUFEN urinal presented at milan design week 2012, undergoes testing at the factory image © designboom

the electronics of LAUFEN’s urinals are built in-house, requiring regular testing image © designboom

the electronics of LAUFEN’s urinals are built in-house, requiring regular testing image © designboom

the grinding area and quality and inspection areas, followed by views within the warehouse video © designboom

all the thoroughly tested pieces are now ready to be packaged on the LAUFEN factory floor, for storage onsite or transport to LAUFEN sellers worldwide.

factory view of the storage area with recently inspected pieces in the foreground image © designboom

factory view of the storage area with recently inspected pieces in the foreground image © designboom

stay tuned for our continued factory visit feature, where we’ll look more at the design strategies behind LAUFEN!

happening now! in an exclusive interview with designbooom, CMP design studio reveals the backstory of woven chair griante — a collection that celebrates twenty years of Pedrali’s establishment of its wooden division.