klaas kuiken uses a lost-foam casting technique to mould ‘EPS’ collection

all images courtesy of klaas kuiken

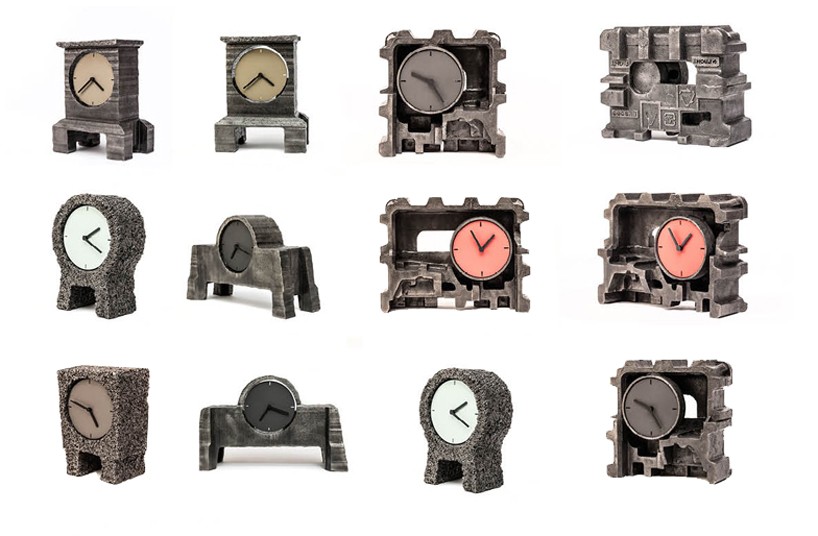

lost-foam casting (LFC) is a type of evaporative-pattern casting process, which is often used for the production of engine parts. klaas kuiken became interested in this method and aimed to challenge its original use by creating interesting products outside of an industrial setting. the designer chose this technique for his ‘EPS’ collection of clocks and wood stoves, which are all originally made from a polystyrene foam mould.

the ‘cut-out’ clock

kuiken began by making different designs and moulds out of the polystyrene foam (styrofoam) which were placed in a sand-filled container. hot cast iron was then poured into the matrix making the foam melt – because of the incredible heat, it allowed the cast iron to take its place. the result is an exact copy of the polystyrene foam design, cast in one single piece that still shows the texture of the mould which was originally used.

the ‘EPS clocks

the ‘EPS’ clocks and stoves reference the material’s industrial use through their engine like appearance. although they contain brutal mechanical features, they express a playful quality through their irregular shapes. kuiken uses two different textures, including; ‘hand peeled’ foam which forms an irregular silhouette; and a hot filament which creates a smooth profile.

‘hand-peeled’ round and square stove

‘cut out’ round and square stove

the ‘EPS’ stoves

molten cast iron being poured into the mould

hot cast iron is poured into the container which causes the foam to melt

the stove cooling down

the mould being extracted form the container

designboom has received this project from our ‘DIY submissions‘ feature, where we welcome our readers to submit their own work for publication. see more project submissions from our readers here.

edited by: hollie smith | designboom