joris de groot is a designer searching for the connection between craftsmanship and industry in his work. interested in collaborating with the industry, the designer creates his own workplace within the factory grounds. once familiar with the process of the existing techniques, he experiments with the available machinery and materials for new innovative uses. for the manufacturer low & bonar’s in4nite II project, studio joris de groot has carefully examined the various techniques that are applied in the manufacturing of car interiors, and translated them into a collection of shoes.

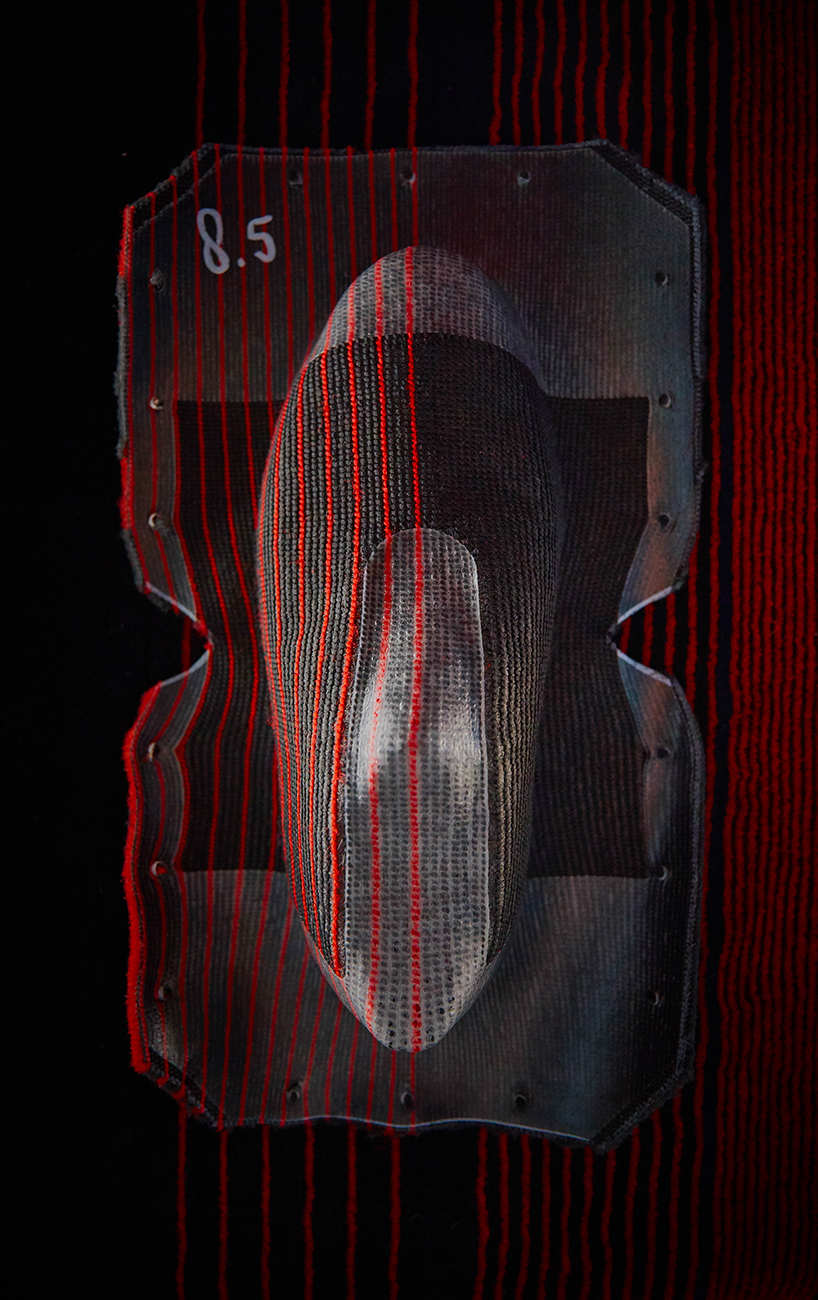

by molding the tufted material, the underlying colback material becomes visible in the design

all photos by studio collector unless stated otherwise

one of the current uses for low & bonar’s material colback® is its implementation in the automotive industry, where it is incorporated in the upholstery of car interiors. having researched the materials that comprise car upholstery, de groot shifted his focus towards the molding of the material.

sneaker detail

in the research and development center of low & bonar, the quality of the material is tested in order to minimize irregularities within the interior. a linear pattern is applied in this molding process to monitor the ways in which the material behaves when it is formed. de groot appropriated the technology in a new way by converting it to form shoes. during this process, he explored the tufted colback® material by playing with the linear patterns; the details and inconsistencies that emerged, constituted the aesthetic character of his collection.

the soles are made from lightweight EVA foam

a linear pattern is used in the molding process of car upholstery to monitor the way the material behaves when it is formed

to attach the upper part to the sole and round off the edges of the design, the festoon technique has been used

loafer model where the carpet is reversed so that the inside of the shoe has the soft surface of the it

the sandal sneaker

a sneaker with reinforced laminated parts — the soft side of the carpet is folded outwards in the shoe, which makes both sides of the carpet visible

2000N is the force with which the mold is pressed into the carpet, to form the shoe

the outside of the shoe is the back of the car carpet — the inside has the soft surface of the carpet

experiment 8.5, moulded carpet

joris de groot describes his idea

the carpet is molded in the same way that car upholstery gets shaped

photo by kris van gendt

project info:

designer: joris de groot

collaboration: low & bonar

material: colback®

photography: studio collector, kris van gendt