racks of game worn shoes from Nike athletes

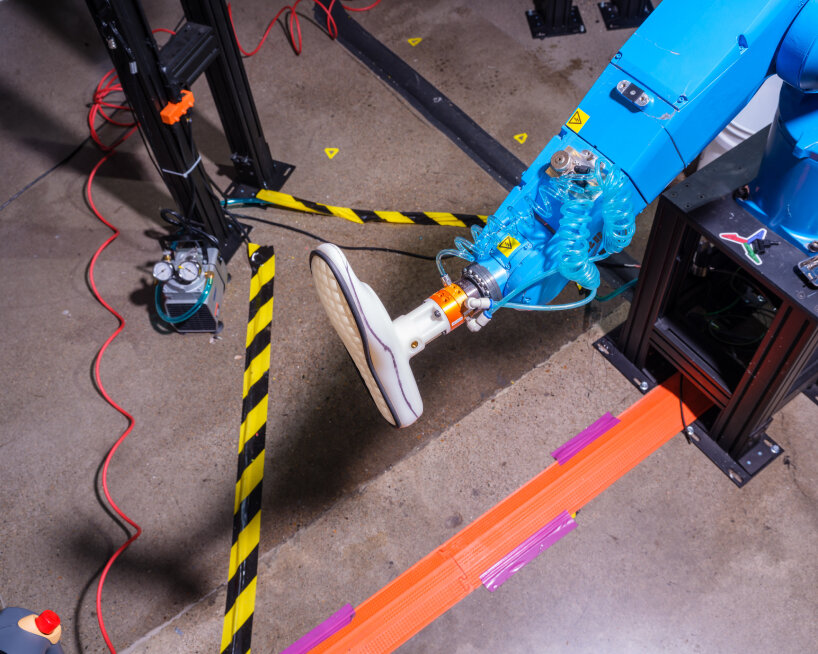

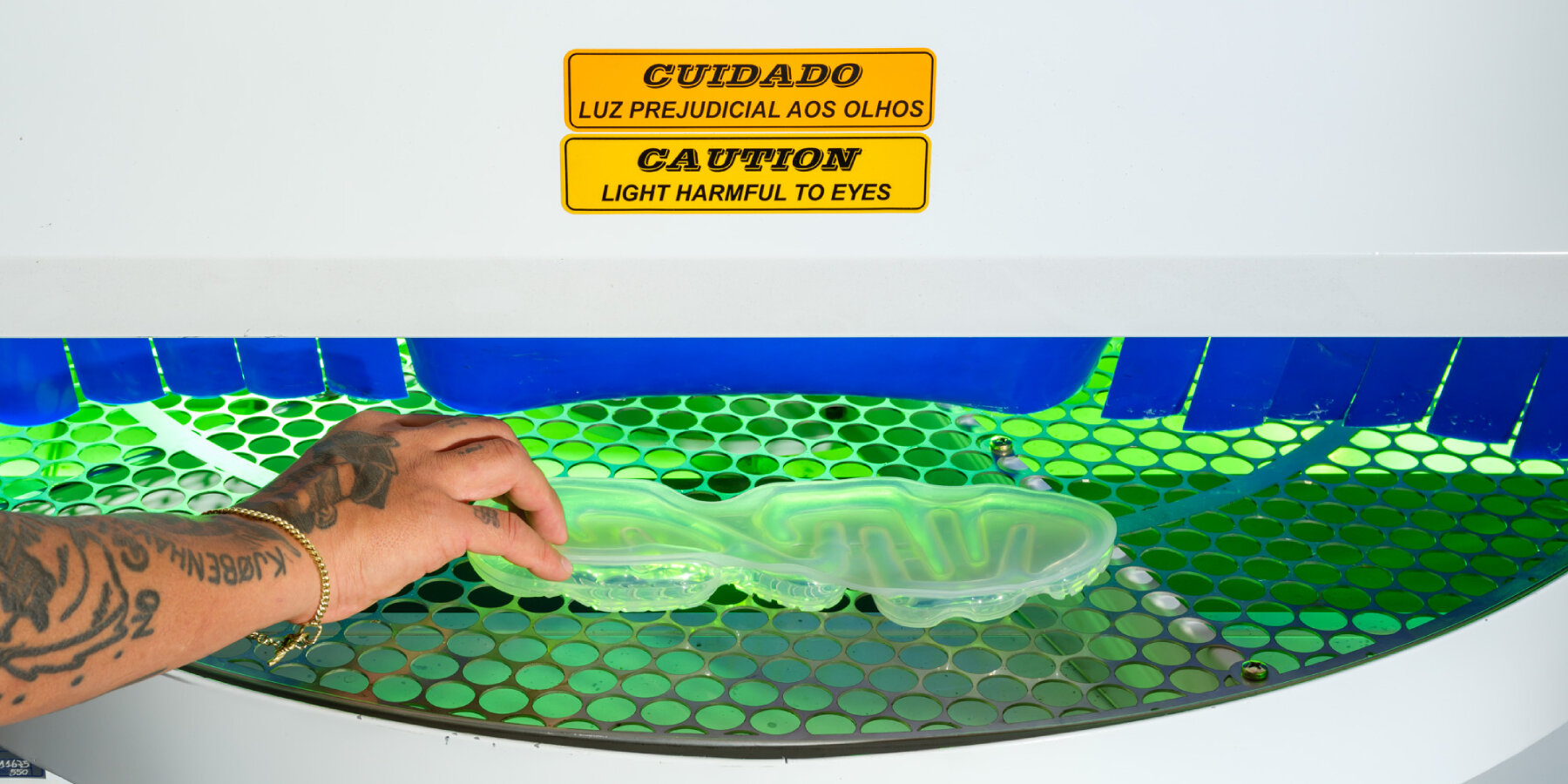

UV oven cures a primed outsole in preparation for assembly

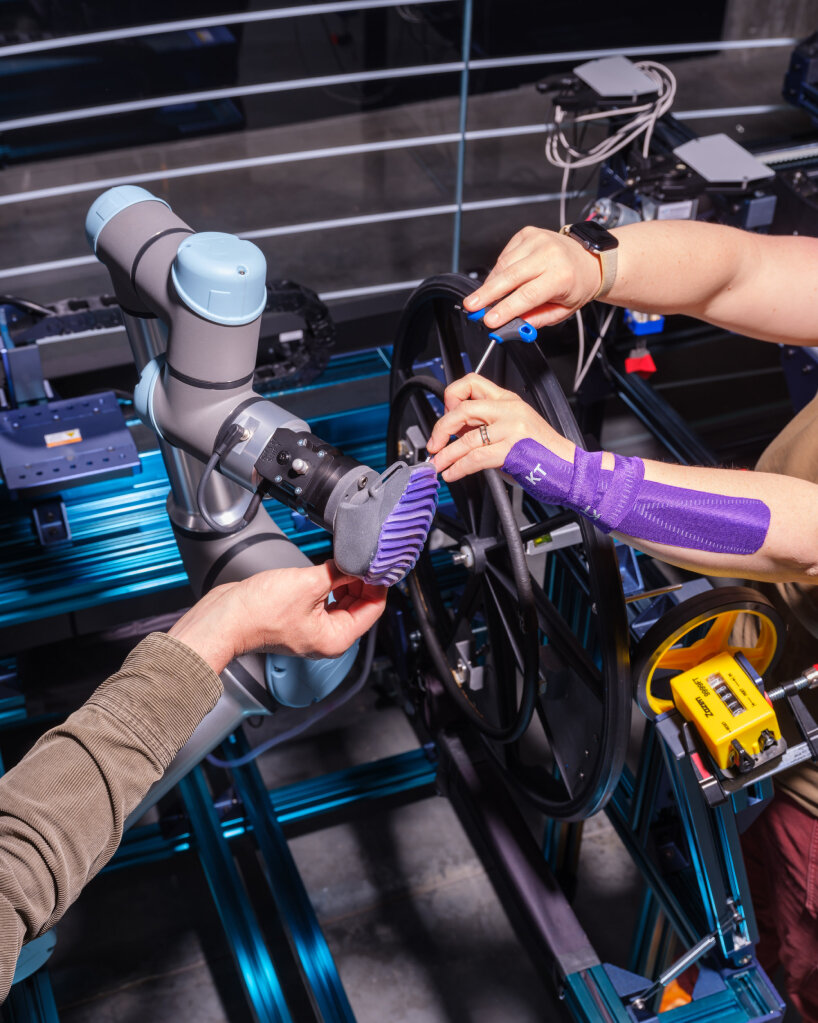

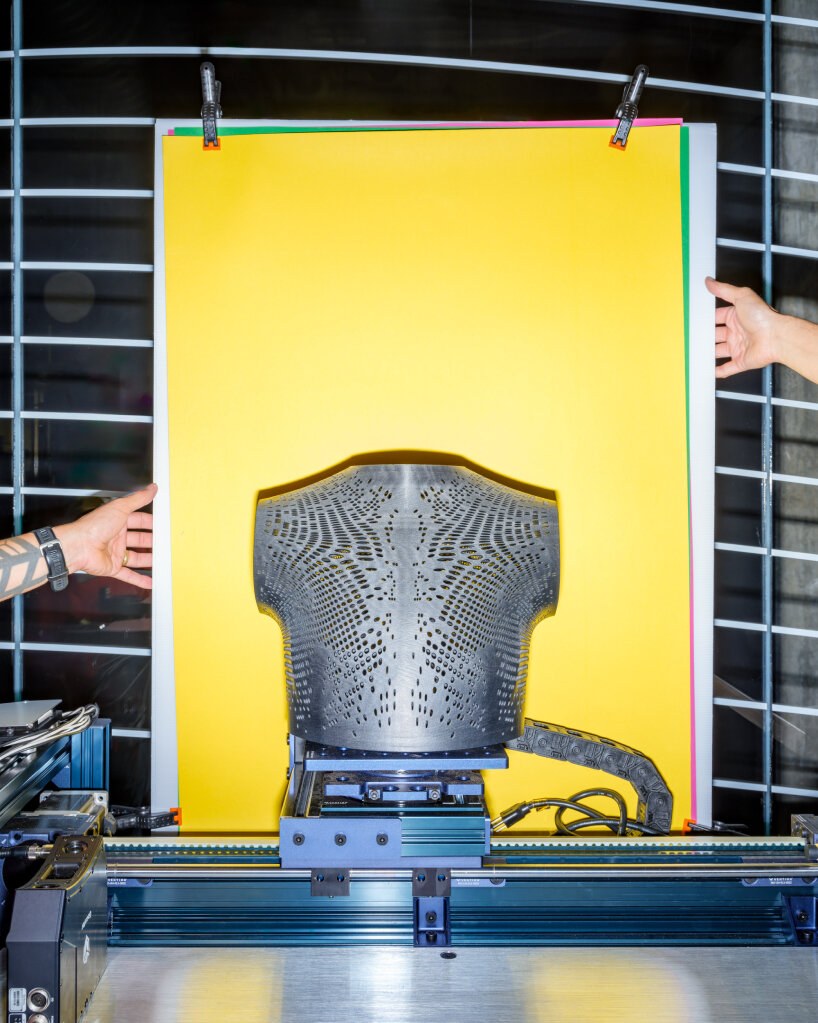

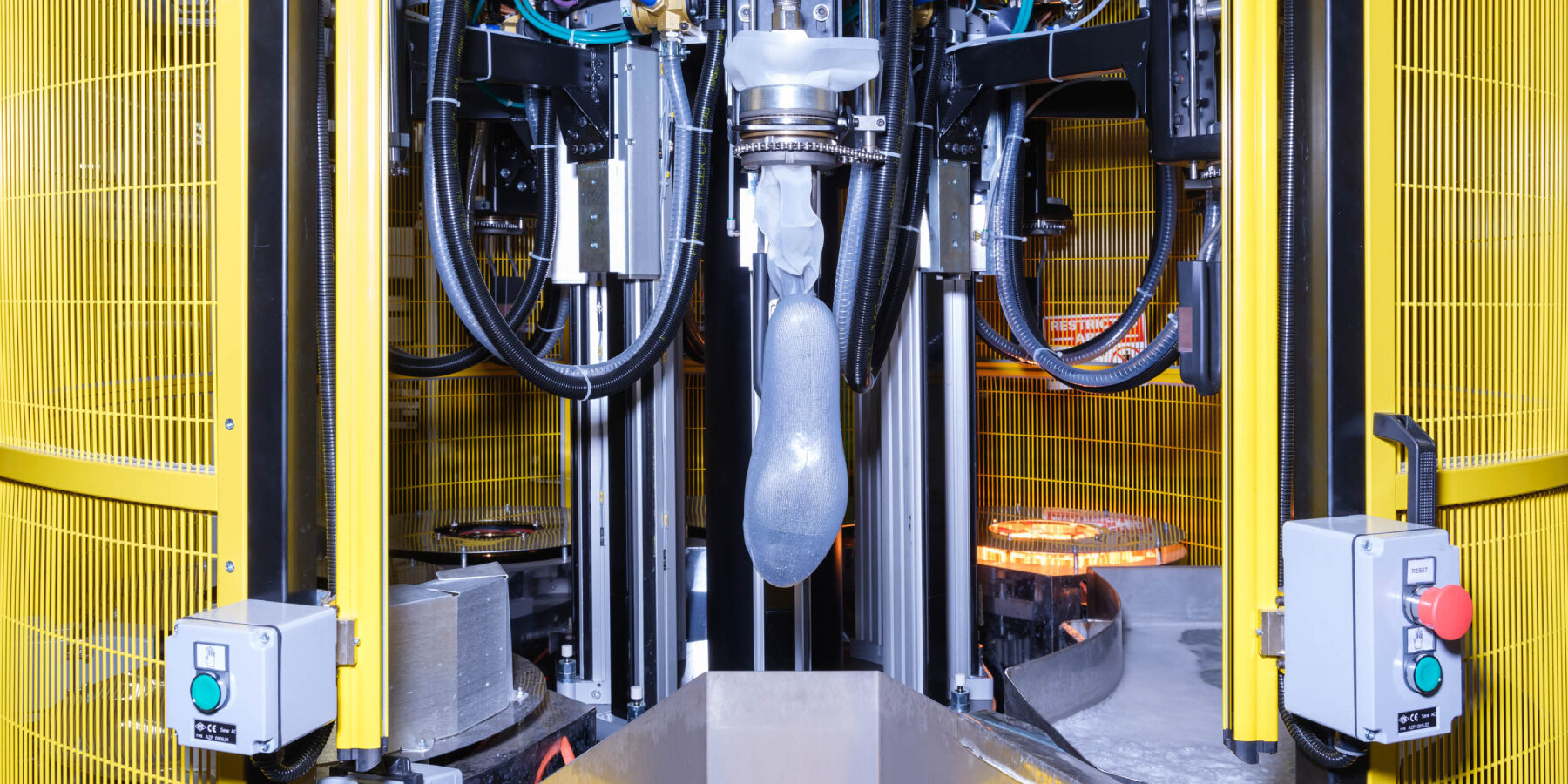

machinery and shoe prototype view

KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

sara shakeel talks the role of AI in contemporary art, the human impulse to materialize digital ideas, and the emergence of phygital works.

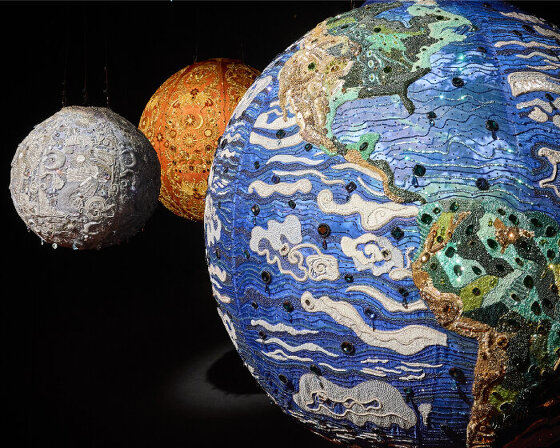

outdoor subterranean oculi, called skyspaces, will frame the shifting hues of the sky to reveal phenomena rarely visible to the naked eye.

visionary director and artist david lynch has passed away on january 16th, 2025, at the age of 78.

connections: +110

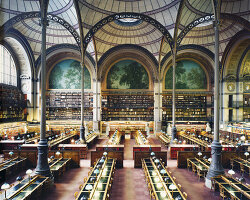

the largest exhibition dedicated to the artist in france is now on view at the grand palais in paris, bringing together large-scale installations, sculptures, photographs, drawings, performance videos and archive documents.