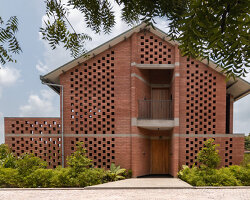

situated on the lawn of the CEPT university campus in ahmedabad, india, WEsearch lab has built a temporary structure that explores a labor intensive, low-cost type of architecture in south-east asian countries. dubbed the ‘wormhole’ installation, the project has been developed with a budget of just 200 usd, using inexpensive building materials.

WEsearch lab recently built the wormhole installation in CEPT university, ahmedabad, india

images by joy mondal, abhimanyu setia and kumaresh ghosh

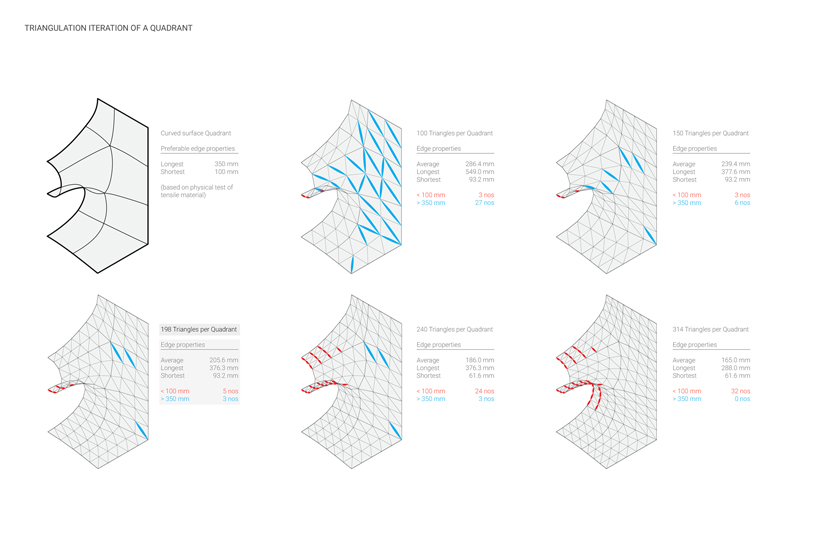

developing south-east asian countries typically don’t have access to cheap or large scale 3-axial 3D printing, 5-axial robot assisted printing, double-curved metal bending or robot assisted assembly infrastructure. on the other hand, they have an abundance of cheap manual labor, and readily available and cheap planar fabrication techniques. to minimize inflation of cost, free-form shapes need to be rationalized into planar parts which can then be fabricated using laser cutting or a CNC milling machine and assembled by hand.

the project explores a labor intensive, low-cost workflow of assembling laser cut pieces

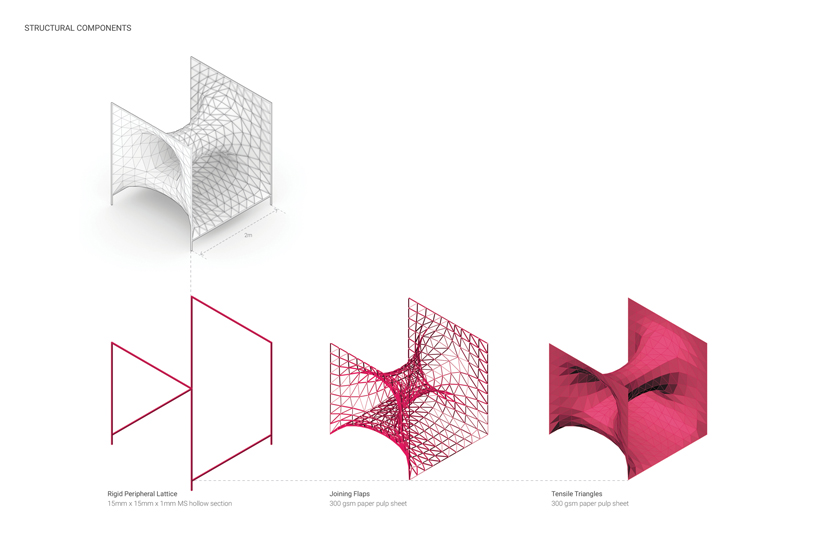

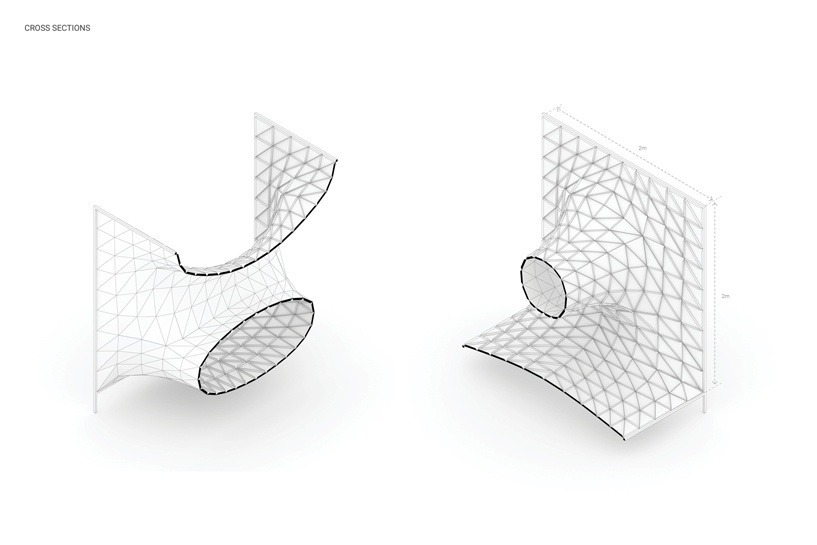

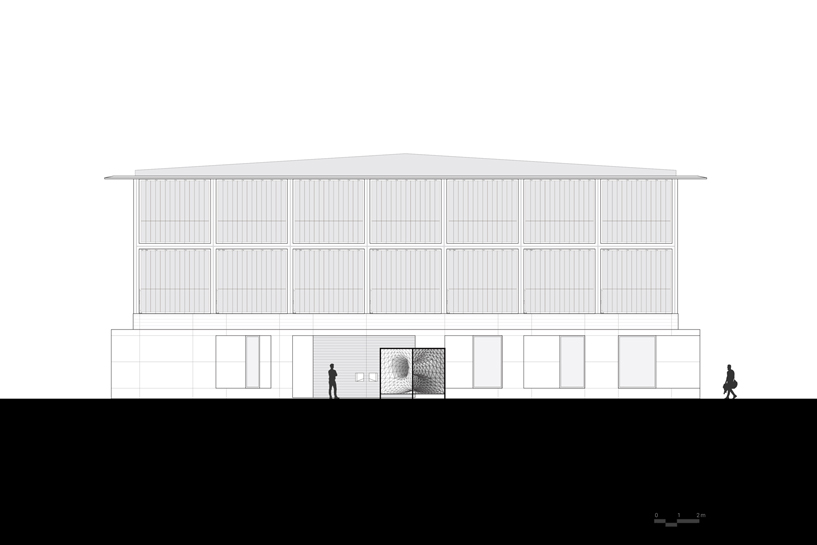

located in front of the main library, which is characterized by strong horizontal and vertical lines, the installation begins with an orthogonal cube shape to respect the surrounding architecture. using this 2m x 2m x 2m box as a starting point, WEsearch lab then designed a wormhole-shaped faceted skin. to build the skin, 792 custom pieces (triangles with flaps) of 300 gsm paper pulp sheets are joined by 10mm wide staples and supported by a 15mm x 15mm x 1mm ms hollow section running along the periphery.

inside a cubic bounding frame, the surface is designed with a gradual introduction of double-curvature

inside the cubic bounding frame, the surface bends in both directions to produce two tube-like holes. the shape of the surface strikes a balance between respecting the surrounding graphical lines and drawing attention from passersby. from a distance, the peripheral cube lines draw the eye, while on closer inspection, the curvature of the self-warped holes halts the eyes of onlookers.

the surface exhibits bending in both directions to produce two tube-like holes

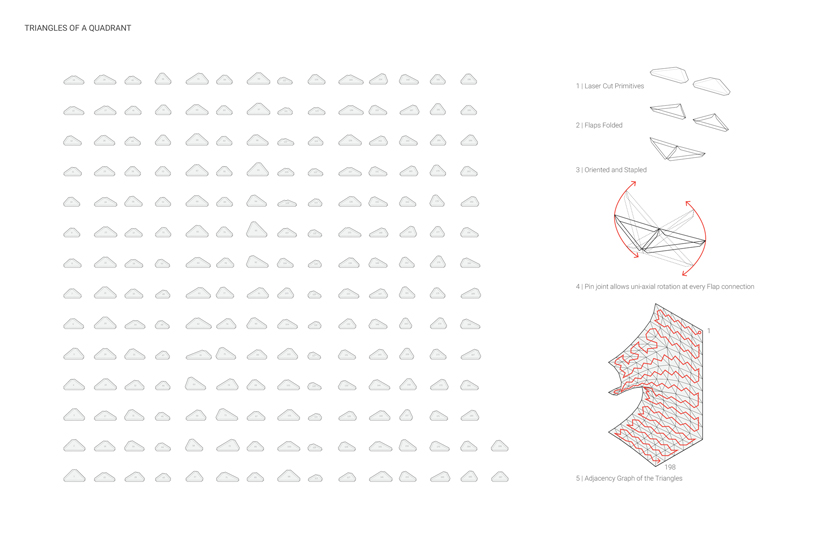

the digital aspect of designing the shape of the surface comprised three steps. firstly, 3D modelling software was utilized to conceive the free-form surface, then it was split into triangular pieces to allow the double-curvature of the structure. finally, a fabrication drawing was generated by flattening and numbering the triangular pieces, and adding flaps for staple connections.

on closer inspection, the curvature of the self-warped holes halts the eyes of an onlooker

the rationalisation of the double-curved surface into triangles is informed by the material properties of the 300 gsm paper pulp sheets. given the self-weight of the sheets and the size of the installation, the maximum allowed length of a triangle edge is calculated to be 350mm. for ease of handling, the minimum allowed length of a triangle edge is ascertained to be 100mm.

the rationalization is informed by the material properties of the 300 gsm paper pulp sheets

each quadrant of the installation is built with 198 triangular pieces, which are formed using a laser cutter. the half-cut flaps are then manually folded and stapled to each other. the triangles and flaps are numbered, which allows easy one-to-one assembly of the triangles. when all the four quadrants are fastened to the peripheral metal frame, the skin loses its amorphous nature and becomes a rigid tensile structure.

the maximum length of a triangle edge is calculated to be 350mm

for ease of handling, the minimum allowed length of a triangle edge is ascertained to be 100mm

each quadrant of the installation is built with 198 triangular pieces

the half-cut flaps are simply folded and stapled to each other

the installation is literally a wormhole-shaped faceted skin within in a 2m x 2m x 2m cube

the shape of the surface strikes a balance between respecting the surrounding graphical lines and drawing attention from passersby

project info:

project name: the wormhole installation

design: joy mondal, WEsearch lab

team: aashini sheth, abhimanyu setia, aditi ashish kanodia, archit milind kathale, dhaval sardhara, kritika bodkhe, kumaresh ghosh, madhurima kumar, mit vasant patel, palak chokssi, payal vaswani, priyankita pant, raj rajeswari sahoo, salonee nadkarni, shashank trivedi, tunisha, vipul raj and viral mehta.

location: cept university, ahmedabad, india

installation size: 2m x 2m x 2m

cost: 200 usd or 14,000 inr

material: 300 gsm paper pulp sheet for the triangular pieces; 10mm wide wire staple to fasten the triangular pieces and 15mm x 15mm x 1mm ms hollow section for the periphery lattice

pieces: 792 custom triangular pieces with flaps

photography: joy mondal, abhimanyu setia and kumaresh ghosh

designboom has received this project from our ‘DIY submissions‘ feature, where we welcome our readers to submit their own work for publication. see more project submissions from our readers here.

edited by: lynne myers | designboom