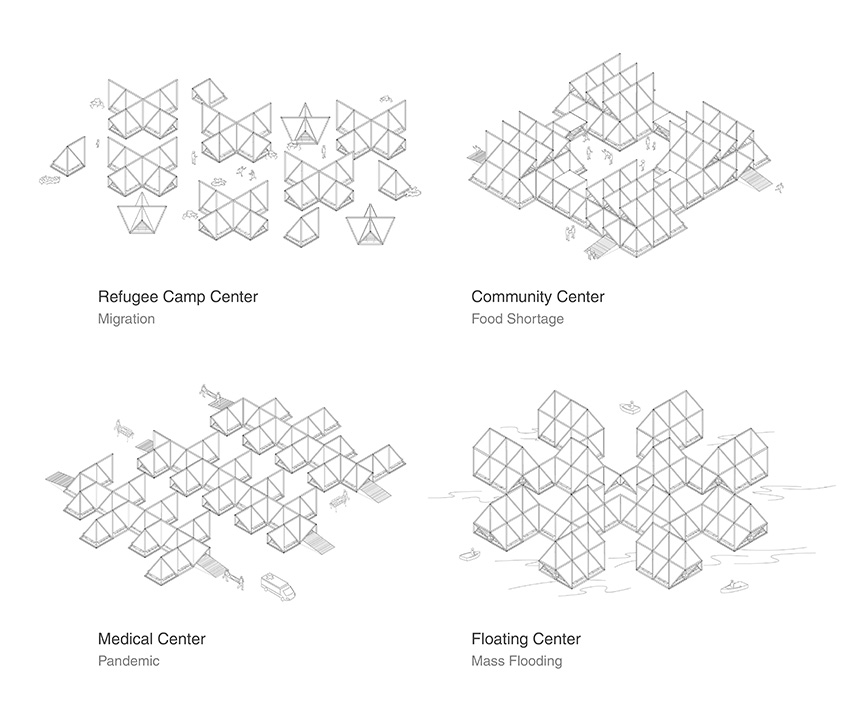

TU delft students francisca hamilton, nathan ngo and thanat prathnadi introduce ‘ponya’, a modular emergency operations center for disaster-struck communities within sub-saharan africa. the system was designed to maximize its potential use across a multitude of emergency scenarios ranging from natural disasters to social conflicts. based on triangular geometry, the form becomes highly adaptable according to the scenario’s site, scale, and temporality.

aerial view

all images courtesy of fransisca hamilton, nathan ngo and thanat prathnadi

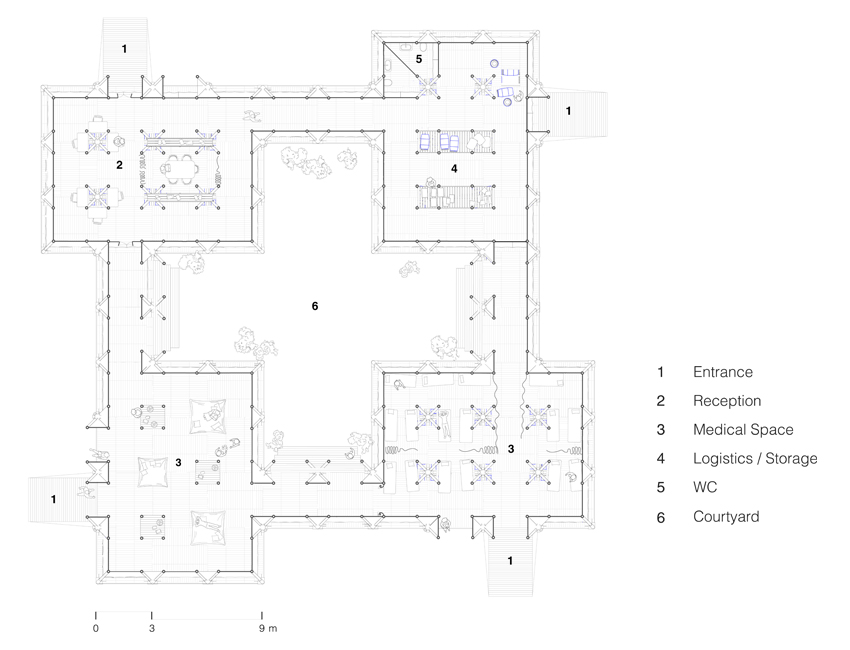

the human-centric approach to ‘ponya’ by hamilton, ngo and prathnadi, begins with the scale of the singular module, being large enough to shelter a family of six, yet low enough to encourage a sense of refuge. for the construction of an emergency operations center (EOC), modules can be connected in all three-axes depending on the required capacity and program. internally, the division of spaces is created using ePTFE tarps and curtains, allowing programmatic flexibility based on the progress of a scenario.

exterior view

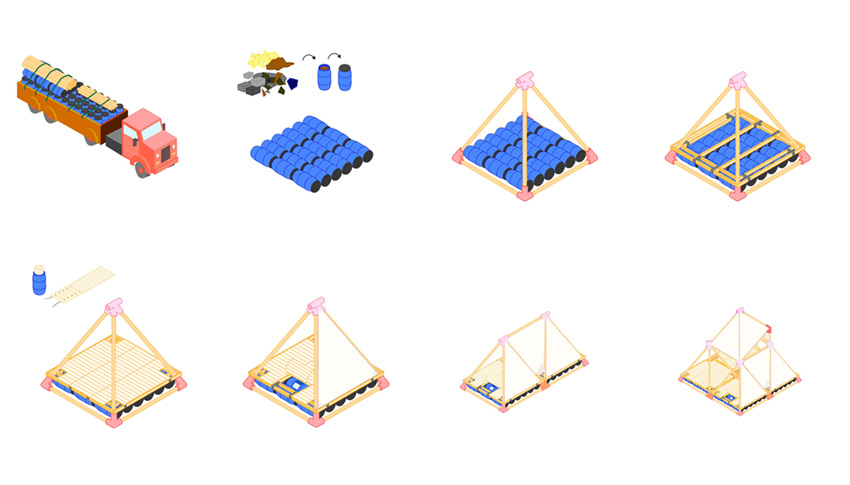

based on the structural integrity of a pyramid, the aesthetic is found in the flexibility and simplicity of a singular module. this is expressed in the composition of three primary materials: blue plastic water barrels as the foundation, bamboo vulgaris as the structure and 3D printed PETG members as the joinery. the intention behind the selection of locally sourced materials, and the overall simplicity of the project, is to ensure that this system can be efficiently assembled, dismantled, and reassembled without the use of power tools or machinery. internally, the triangular structure provides opportunities for elevated shelves and secure storage whilst the floor with its tensed slat structure can be rolled up in order to access the barrels below. when the EOC is in response to flooding, the barrels can be emptied and sealed, enabling the structure to float and keeping the interior dry.

interior view

in ‘ponya’, the onsite construction includes the assembly of all the pre-fabricated components. to lower the manufacturing costs and simplify the process, a maximum of fourteen component types are required to erect an EOC of any scale and form. most noticeably, all bamboo members are of the same length, and the six different joinery members are color-coded depending on their placement. the EOC would rely solely on passive cooling, heating, and ventilation through the manipulation of openings, double-height spaces, and overhangs. circularity occurs on the scale of the system and that of its components and materials.

flood struck community

‘ponya’ as a system has been designed with a temporal and adaptable objective. by investing in PETG filament printing, the joinery components can withstand harsh conditions without deforming and eroding in the socket areas. the use of ePTFE tarps as a durable heat-resistant and hydrophobic fabric can be repeatedly used despite varying conditions between sites. in addition, locally sourced bamboo vulgaris and caissadra timber for the flooring, fuels the local economies and reduces the project’s net carbon footprint.

plan

scenarios

construction process

project info:

name: ‘ponya’

architects: francisca hamilton, nathan ngo, thanat prathnadi

designboom has received this project from our ‘DIY submissions‘ feature, where we welcome our readers to submit their own work for publication. see more project submissions from our readers here.

edited by: myrto katsikopoulou | designboom