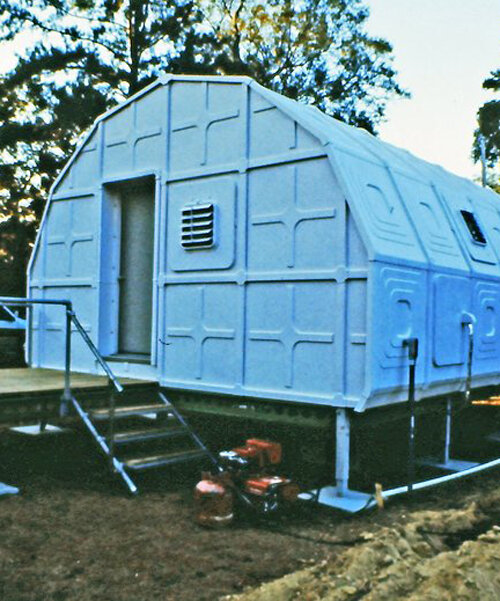

in the mid 1980s, michael jantzen designed a modular, prefabricated and energy efficient building system that could be assembled almost anywhere, even in remote locations. the basic idea was to create flexible living spaces that could be erected in a short time by two people using simple hand tools, without the need for heavy equipment.

the completed structure was used by NASA as an experimental habitation lab

images courtesy of michael jantzen

the structures had to be very strong and the components had to be lightweight for self-assembly but heavily insulated in order to reduce the amount of energy required for heating and cooling the interiors. the basic building components also had to be designed so they could be easily assembled to form many different sizes and shapes. in addition, the building system had to include its own modular steel frames onto which the insulated structural components could be attached in order to eliminate the need for conventional foundations.

the first off-grid solar powered buildings clad with thermoformed recyclable plastic

jantzen also set himself the challenge to design all of the components in a way that did not require any kind of conventional fasteners such as nails, screws or bolts. as the structures were developed for use in remote areas, it was also desirable to create a system that could function completely off of the conventional energy grid.

aerial view of the building system

the final design focused on the creation of a series of insulated structural wood panels that clipped together to form arches and half arches, which in turn formed full and half vaults. the vaults were assembled onto elevated modular steel frames that locked together and sat onto self-leveling structural support legs and footpads anchored into the ground. the full and half vaults could be assembled together into many different shapes and sizes to accommodate many different kinds of uses.

the steel support frame that locked together and was elevated above the ground with self-leveling support legs and foot pads that are anchored to the ground

the insulated structural wood panels could be covered with different kinds of weatherproof cladding, including thermoformed recyclable plastic that was used in the design of the first prototypes. these large thermoformed plastic components simply hooked onto the insulated structural wood panels and overlapped in ways that did not require any kind of additional sealants for waterproofing.

insulated structural wood panels clipped together to form full and half arches, which in turn formed full and half vaulted spaces

the interior finishes functioned in a similar way as the exterior. where the structural insulated panels joined together on the inside, raceways were formed into which quick-connect wiring and plumbing could be placed. interior wall finishing panels of various kinds could be simply hooked onto the structural panels. some of those could contain lights and/or other amenities. in some of jantzen’s designs for the interior panels, complete furniture modules were incorporated that could be folded out of the panels for use inside of the structures.

the wall panels being hooked onto the structural insulated wood panels in the interior

perhaps the most important aspect of the building system is the fact that all of its components could be easily assembled into many different kinds of off-grid habitable structures in remote places. moreover, all of the structures could be just as easily disassembled and reassembled again and again into different kinds of structures for different kinds of uses, in different kinds of places.

interior view

the finished interior of the NASA experimental habitation lab

some of the interior wall finishing panels contained lights and fold-out furniture modules

fold-out storage modules and food preparation modules

media module and table/chairs modules

fold-out bed and storage module

project info:

name: a revolutionary, prefabricated, small-scale, modular, energy efficient, relocatable building system from the mid 1980s

architect: michael jantzen

designboom has received this project from our ‘DIY submissions‘ feature, where we welcome our readers to submit their own work for publication. see more project submissions from our readers here.

edited by: lynne myers | designboom