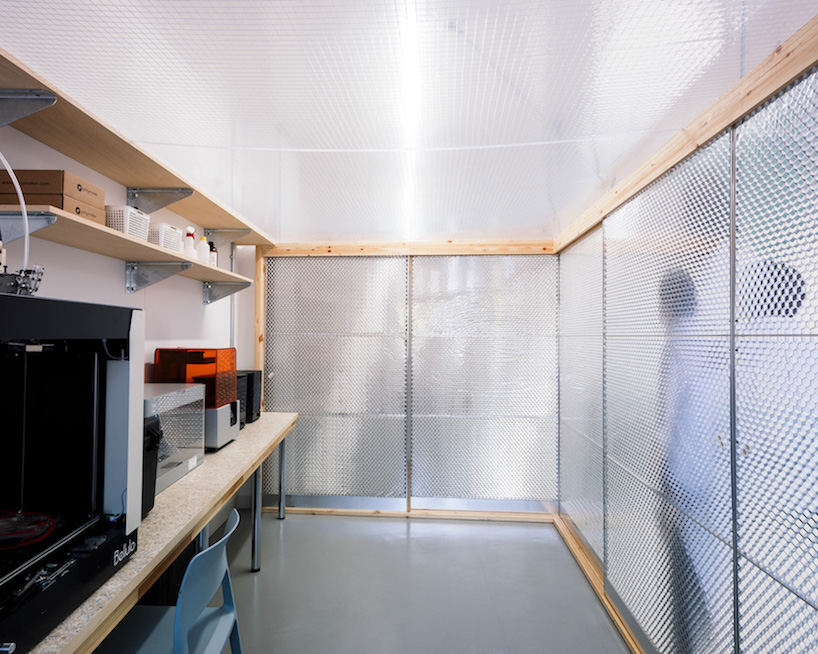

this collaborative work by masaaki iwamoto laboratory + ICADA involves the invention of a new ‘origami-type’ aluminum honeycomb panel, which was utilized to enclose a small digital fabrication workshop, called paper lab, at kyushu university in japan. the project proposes a new alternative to traditional office partitions and cubicles.

the small digital fabrication workshop is enclosed within six honeycomb sliding doors

images by yashiro photo office (unless otherwise stated)

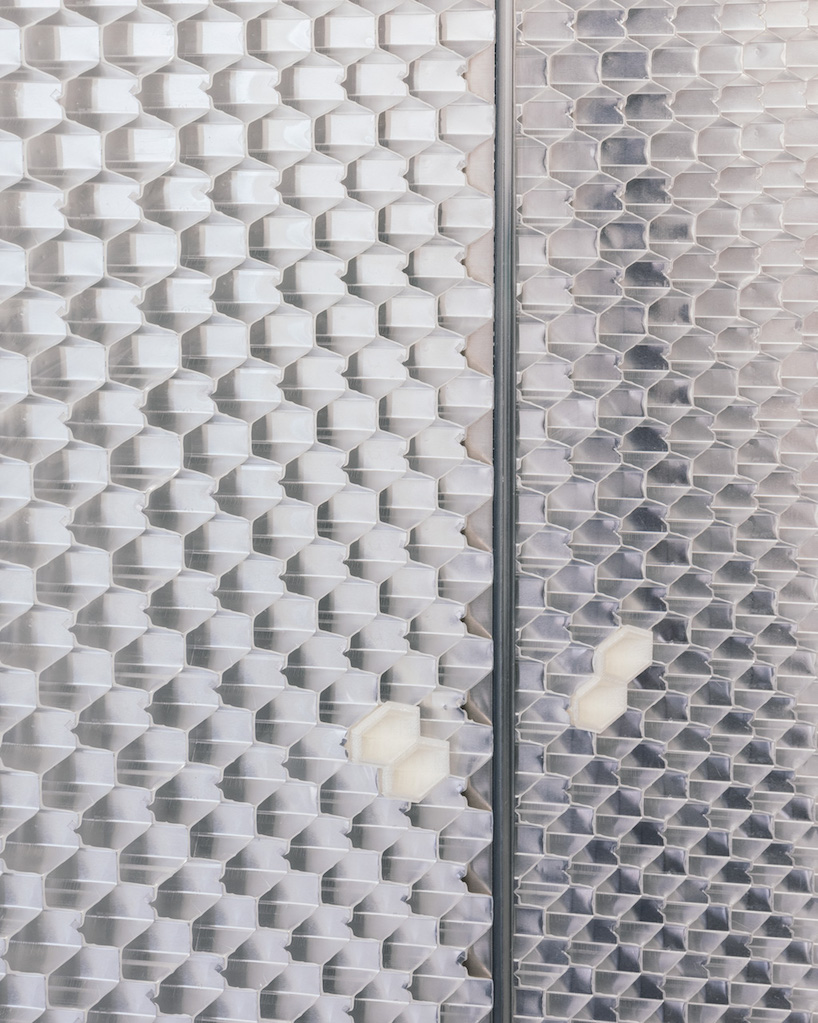

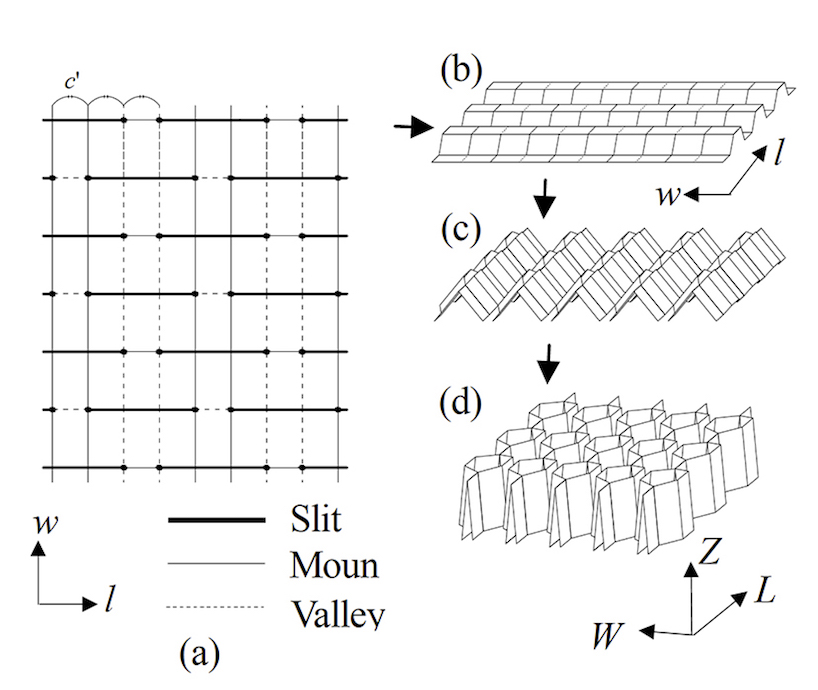

the origami honeycomb panels are made of an aluminum sheet with periodic slits and folded lines. when the sheets are folded, a three-dimensional honeycomb shape is created. compared to the conventional expanded honeycomb, this origami honeycomb is more precise and therefore has the potential to be exposed. furthermore, by adjusting the geometry of origami, it’s possible to create complex shapes such as an oblique, tapered, or curved panel.

the interior of the workshop is most visible from a diagonal view

for paper lab, masaaki iwamoto laboratory + ICADA utilized the oblique honeycomb panels, whose cell dividers incline at 45 degrees to the panel surface. ECTFE film was experimentally used as the face material for the honeycomb cores. it is a new membrane material with high transparency and weather resistance. the honeycomb ‘fusuma’ (japanese style sliding door) is lightweight, weighing just 4.5 kg each, and uses the same simple details as japanese fusuma.

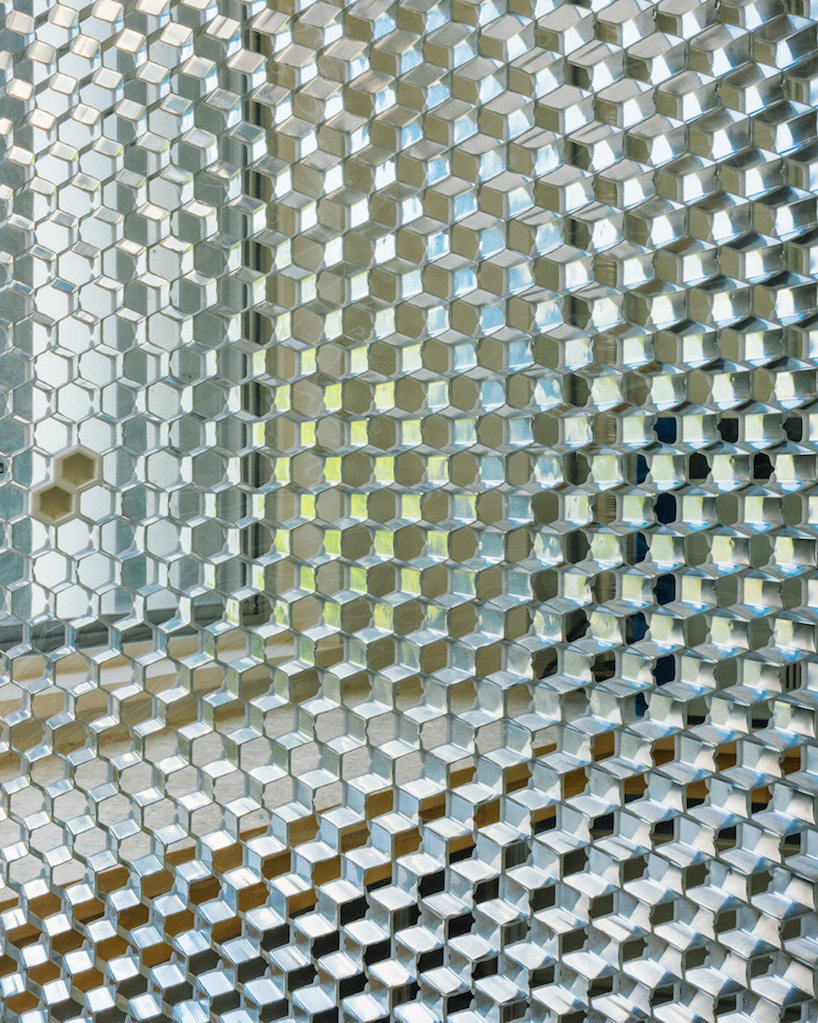

the reflection in the honeycomb cells creates a mysterious visual effect of multiple images

by combining oblique honeycomb panels and highly transparent membrane, the ‘fusuma’ sliding panels produce complex visual effects; reflective, transmissive, and shielding effects in a thickness of only 25 mm. its transparency changes depending on the viewing angle. they are opaque when viewed from the front, but appear to be transparent when viewed from an oblique angle. the reflection in the honeycomb cell creates a unique visual effect of multiple images.

the oblique honeycomb panels create a graduation of transparency

interior of the digital fabrication workshop

3D-printed knobs fit precisely into the honeycomb cores

detail of the oblique honeycomb panel

detail of the honeycomb panel

multiple reflections are created

gradational transparency at night

the light is reflected and diffused through the oblique honeycomb panels

concept of new honeycomb manufacturing: (a) basic folding line diagram, (b)-(d) the transformation process to honeycomb shape.

image © kazuya saito

project info:

project name: paper lab / oblique honeycomb partition

location: fukuoka, japan

status: built march 2020

program: laboratory

designers: masaaki iwamoto, shoichi nakamoto / masaaki iwamoto laboratory, kyushu university

origami engineer: kazuya saito

collaborator: ICADA

contractor: ZOOM

origami panel manufacturer: shiroyama industry company, taiyo kogyo

GFA: 549.93 ft2 (51.09 m2)

photography: yashiro photo office

designboom has received this project from our ‘DIY submissions‘ feature, where we welcome our readers to submit their work for publication. see more project submissions from our readers here.

edited by: lynne myers | designboom