KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

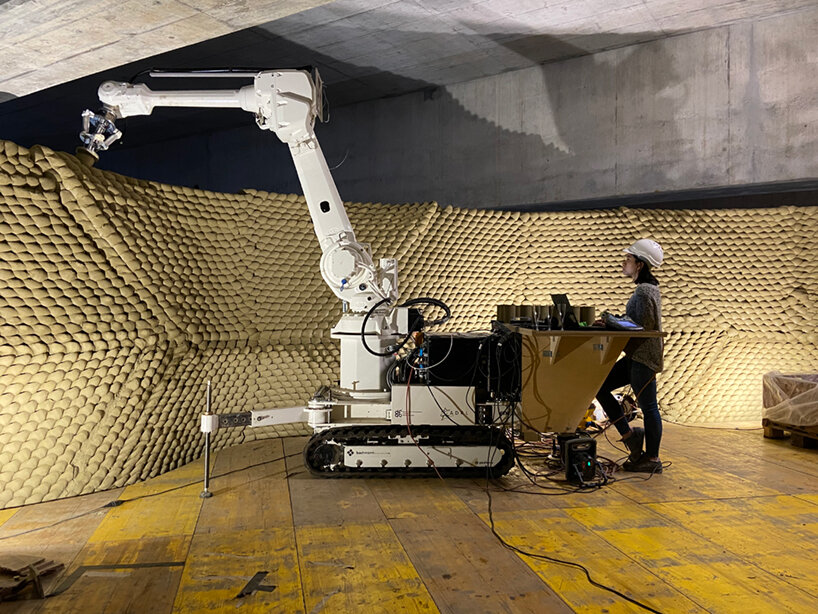

happening now! with sensiterre, florim and matteo thun explore the architectural potential of one of the oldest materials—clay—through a refined and tactile language.

lina ghotmeh notes that the permanent qatar pavilion will offer a platform for diverse arab voices at the venice biennale.

discover all the important information around the 19th international architecture exhibition, as well as the must-see exhibitions and events around venice.

discover ten pavilion designs in the giardini della biennale, and the visionary architects that brought them to life.

connections: 28

we meet carlo ratti in venice to talk about this year's theme, his curatorial approach, and architecture’s role in shaping our future.