digitally produced pre-fabricated hotel by facit homes images © mark bolton

london-based studio facit homes has developed a pre-fabrication system that provides a mobile production facility (MPF) onto the site. the unit includes a full spectrum of building tools and materials necessary to complete the construction of a physical structure. using the drawings from fully defined 3D computer models, a shipping container is transformed into a local manufacturing site, where sheets of sustainable spruce plywood are individually CNC cut according to each the digital files.

the unique ‘D-process’ results in an accurate measurement for material quantity, electrical positioning and plumbing placement for an efficient construction method. build-time for each dwelling chassis can be as quick as three-days based on foundation preparation and site conditions.

pre-fabricated hotel in somerset, UK

pre-fabricated hotel in somerset, UK

the companies recent development includes the design of a pre-fabricated hotel in the trees located in the grounds of the 300 year old grand georgian mansion harptree court near bristol. by working closely with engineers, an innovative structural concept has been created to allow for the framework to be assembled using components that hang off ropes in the the forest. built using entirely natural materials, the facade of the house includes sustainably harvested larch cladding and cedar shingles to cover the roof.

pre-fabricated hotel interior in somerset, UK

pre-fabricated hotel interior in somerset, UK construction process

construction process

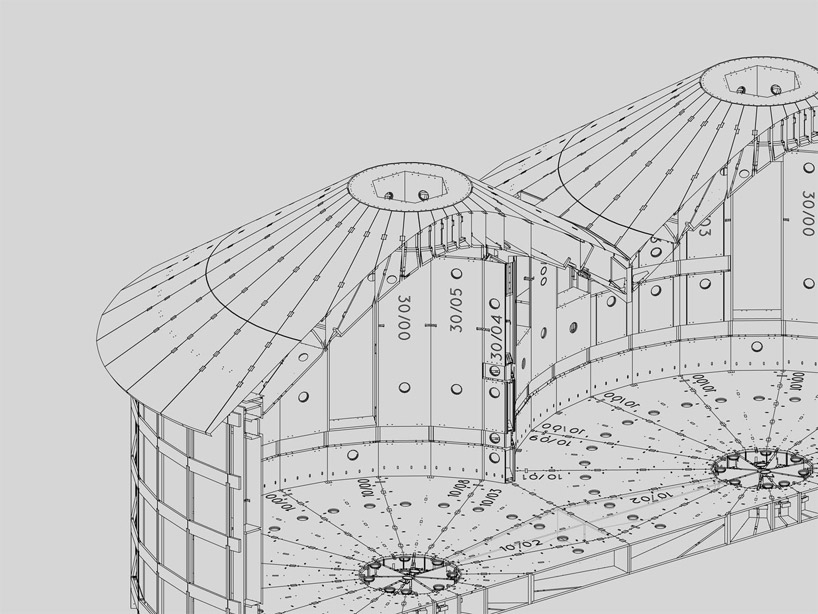

plywood CNC roofing during construction

plywood CNC roofing during construction

pre-fabricated construction assembly for the interior

pre-fabricated construction assembly for the interior

digital file for on-site manufacturing

digital file for on-site manufacturing

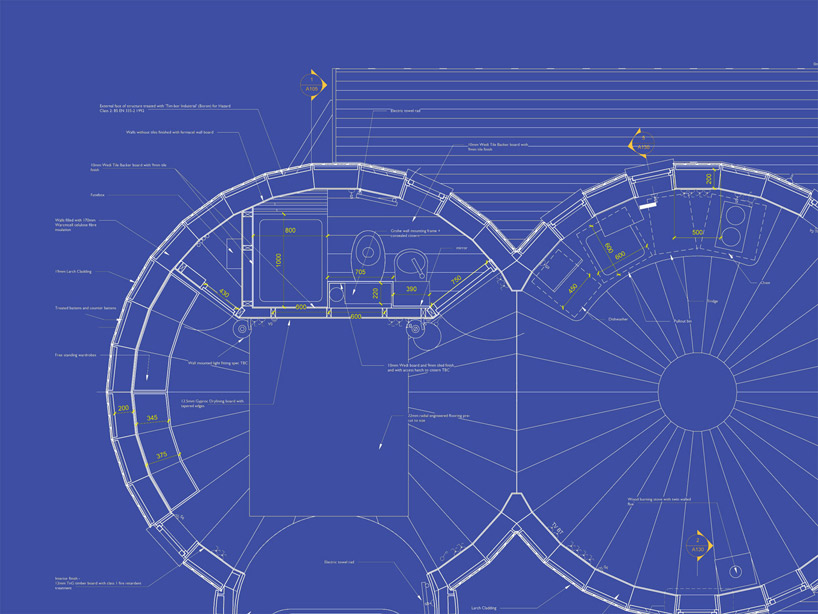

plan for the self-contained hotel apartment sitting under the canopy of a 300 year old oak tree

plan for the self-contained hotel apartment sitting under the canopy of a 300 year old oak tree

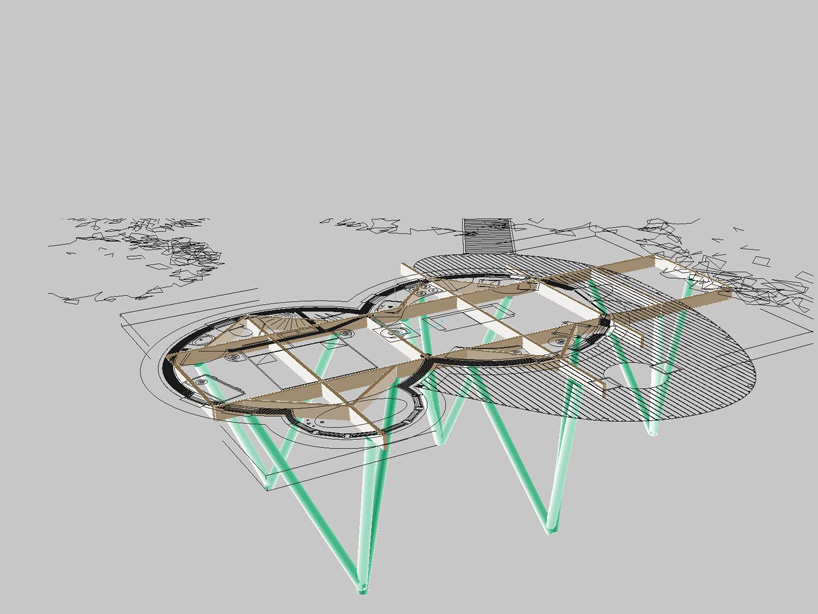

3D model mapping the raised platform for the cylindrical hotel pod structure

3D model mapping the raised platform for the cylindrical hotel pod structure

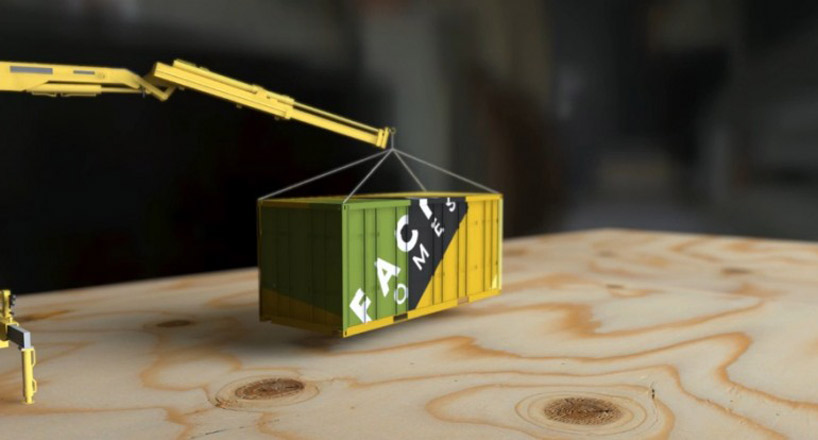

the digital mobile production facility in a shipping container

the digital mobile production facility in a shipping container

CNC detail of the pre-fabricated boards

CNC detail of the pre-fabricated boards

model of the mobile production facility system

model of the mobile production facility system

model of the mobile production facility system

model of the mobile production facility system

facit homes demonstration video