KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

happening now! swiss mobility specialist schindler introduces its 2025 innovation, the schindler X8 elevator, bringing the company’s revolutionary design directly to cities like milan and basel.

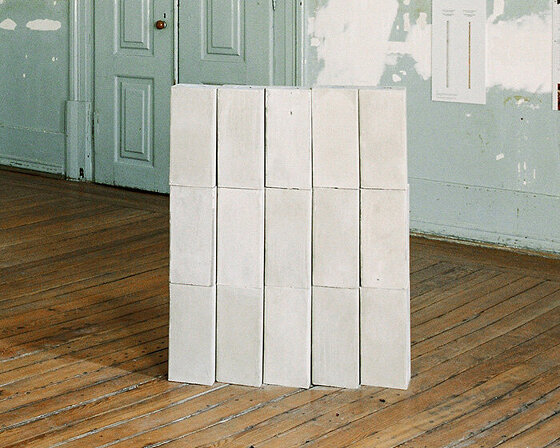

'what if one of the building industry’s most hazardous materials could become one of its most promising?’

connections: +670

with the legendary architect's passing, we are revisiting the buildings that redefined what architecture could look and feel like.

connections: +210

the founders of amateur architecture studio have been appointed curators of the 20th international architecture exhibition, opening may 8th, 2027.

connections: 12

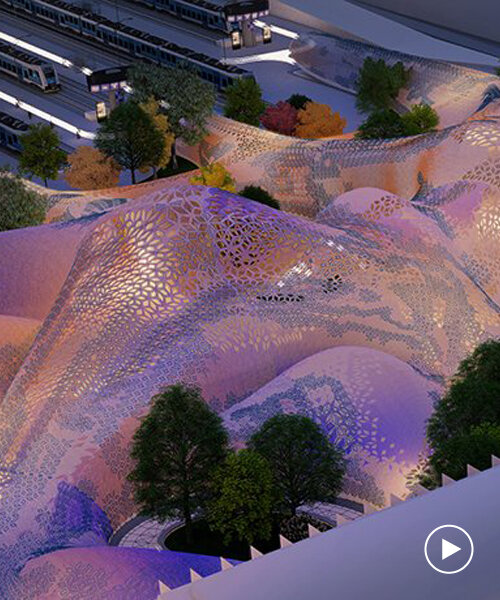

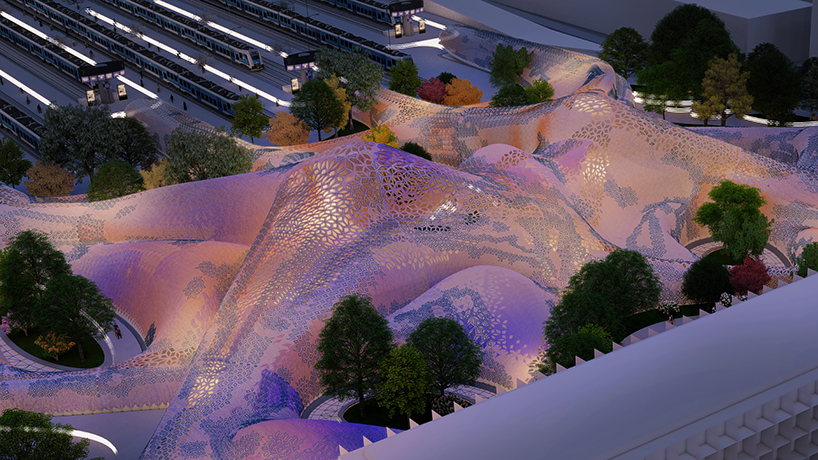

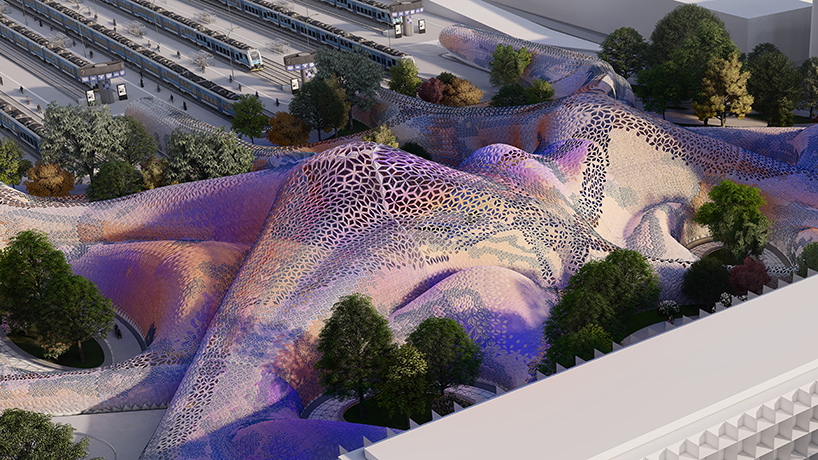

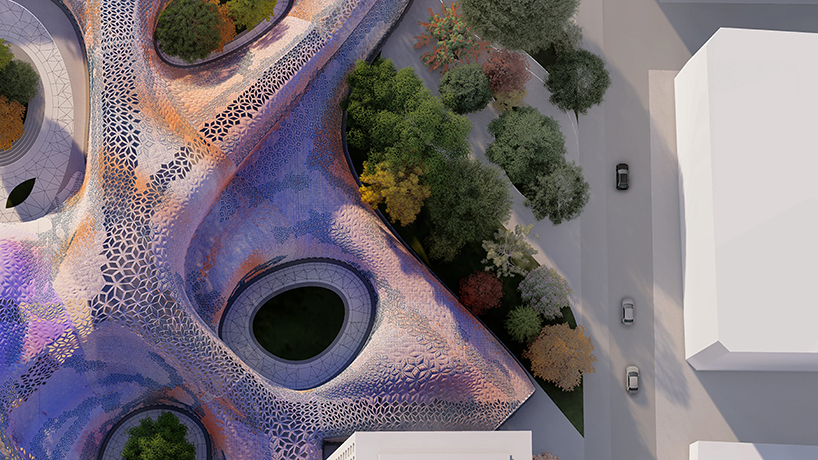

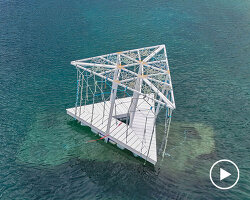

the project sits like a ring placed over the terrain, with its funnel-like roof forming a shaded perimeter walkway and an introverted core.