nature-inspired design in air conditioning systems research

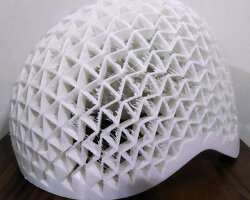

The TerraMound project, led by Rameshwari Jonnalagedda, a student at Bartlett School of Architecture, UCL, fosters energy-efficient buildings capable of adapting to a changing climate. The research draws inspiration from the intricate network of tunnels within termite mounds and reimagines buildings through minimal surfaces. This approach enhances cooling efficiency and transforms structures into dynamic entities that interact with their environment. The project involves creating a 3D printed ceramic structure that mimics the porous architecture of termite mounds. The current TerraMound prototype, a desktop model, serves as a conceptual springboard for the idea. It functions as a cooler with a fan at the base drawing air upwards, inspired by the termite mound’s egress complex. A planter atop the structure provides water that trickles down the cooling tower, leveraging the absorbency of terracotta clay for evaporation. The essence of TerraMound lies in its scalability, envisioning larger structures that harness natural wind for ventilation, turning buildings into breathable entities.

all images courtesy of Rameshwari Jonnalagedda

3D printed ceramic cooling towers act as moisture buffers

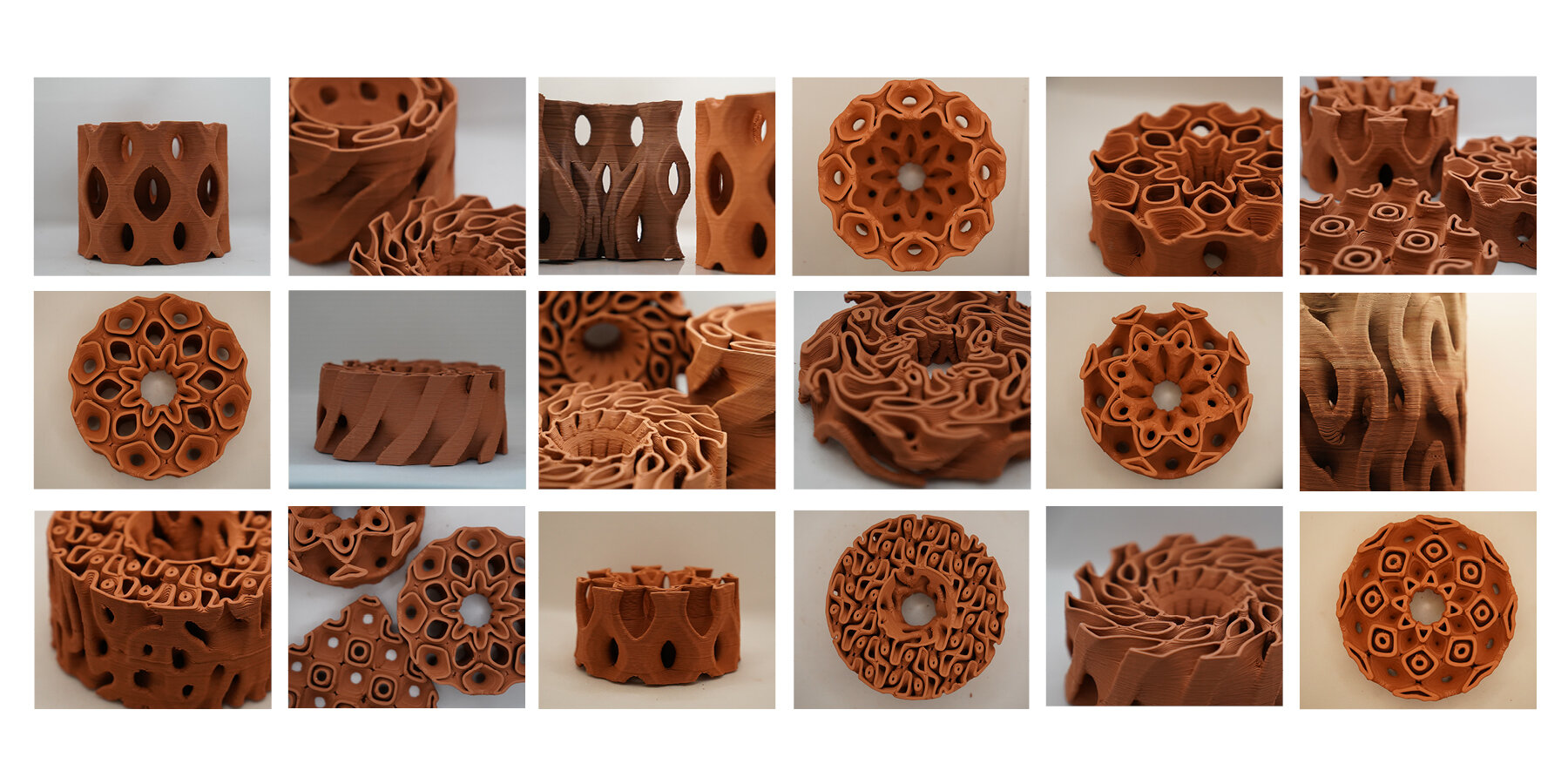

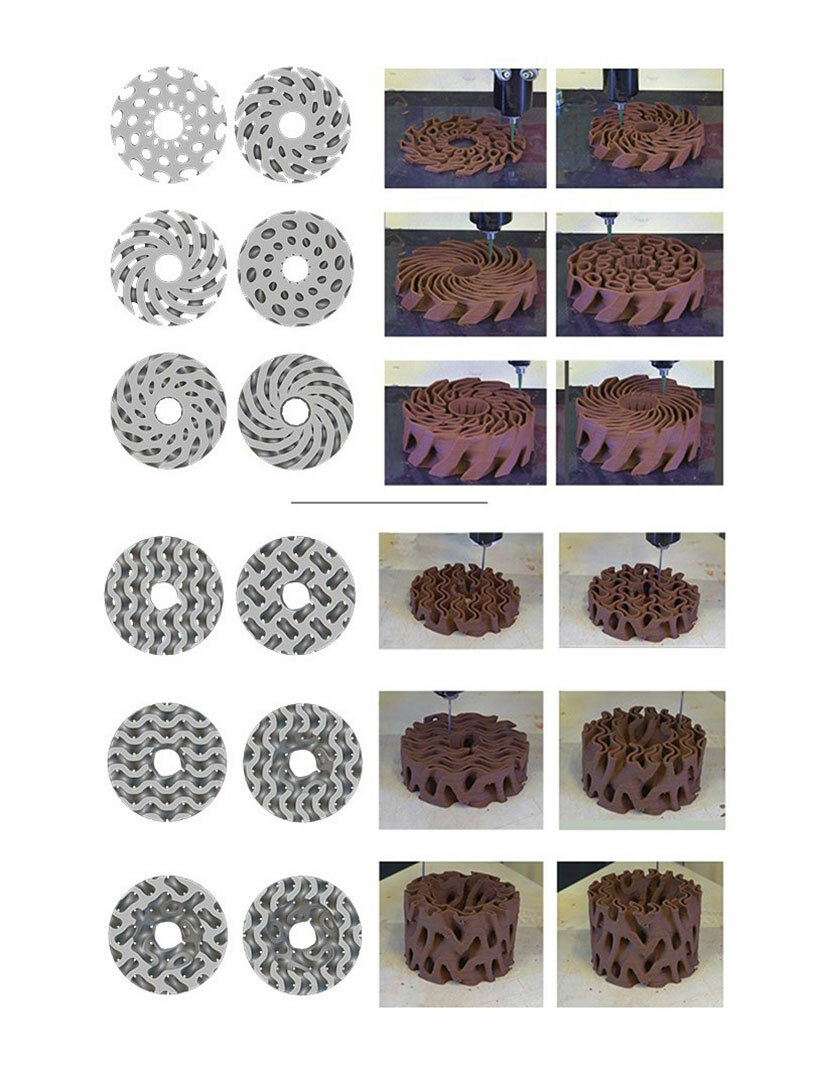

The Delta WASP 4100 3D printer provides precise control over the shape and structure of minimal surfaces. Experimentation with materials like terracotta clay and stone white clay allows the creation of visually and functionally diverse structures. By combining the efficiency of minimal surfaces with the power of 3D printing, Rameshwari has developed a system that reduces energy consumption and also has the potential for energy capture. TerraMound challenges the perception of buildings as static entities and envisions them as living organisms capable of adapting and evolving. Much like termite mounds, these structures would be responsive to their surroundings, regulating temperature and airflow while providing shelter for various species.

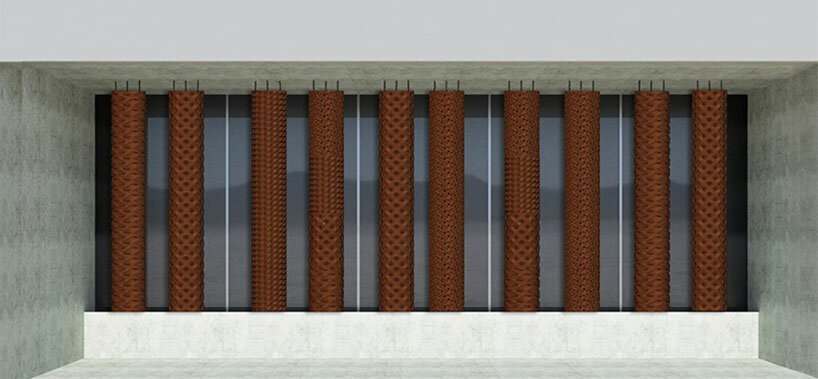

Beyond cooling, the adaptability of minimal surfaces allows for customized porosity and material composition, opening up various applications. These include facade panels, large-scale 3D printed walls, and bio-receptive structures. This research by the Bartlett architecture student marks the beginning of a journey to further explore geometric concepts, materials, and large-scale 3D printing technologies, paving the way for sustainable, bio-inspired designs in construction and environmental integration. By exploring the potential of minimal surfaces and 3D printing, Rameshwari Jonnalagedda is contributing to innovative applications in the built environment, enhancing building performance, reducing energy consumption, and redefining architecture as a dynamic and adaptive discipline.

the TerraMound project draws inspiration from termite mounds

minimal surface geometries develop energy-efficient cooling solutions

these shapes are ideal for optimizing heat exchange

3D printed ceramic structure mimics the porous architecture of termite mounds

the gradient effect is achieved by mixing terracotta clay with stone white clay

various minimal surface geometries with different porosities are 3D printed to study their cooling potential

scaling up these designs creates large cooling towers

minimal surfaces are adaplable, allowing for customized porosity and material composition

project info:

name: TerraMound

designer: Rameshwari Jonnalagedda | @ce.rami.x

tutor: Arthur Prior

B.made staff at Bartlett, UCL

designboom has received this project from our DIY submissions feature, where we welcome our readers to submit their own work for publication. see more project submissions from our readers here.

edited by: thomai tsimpou | designboom