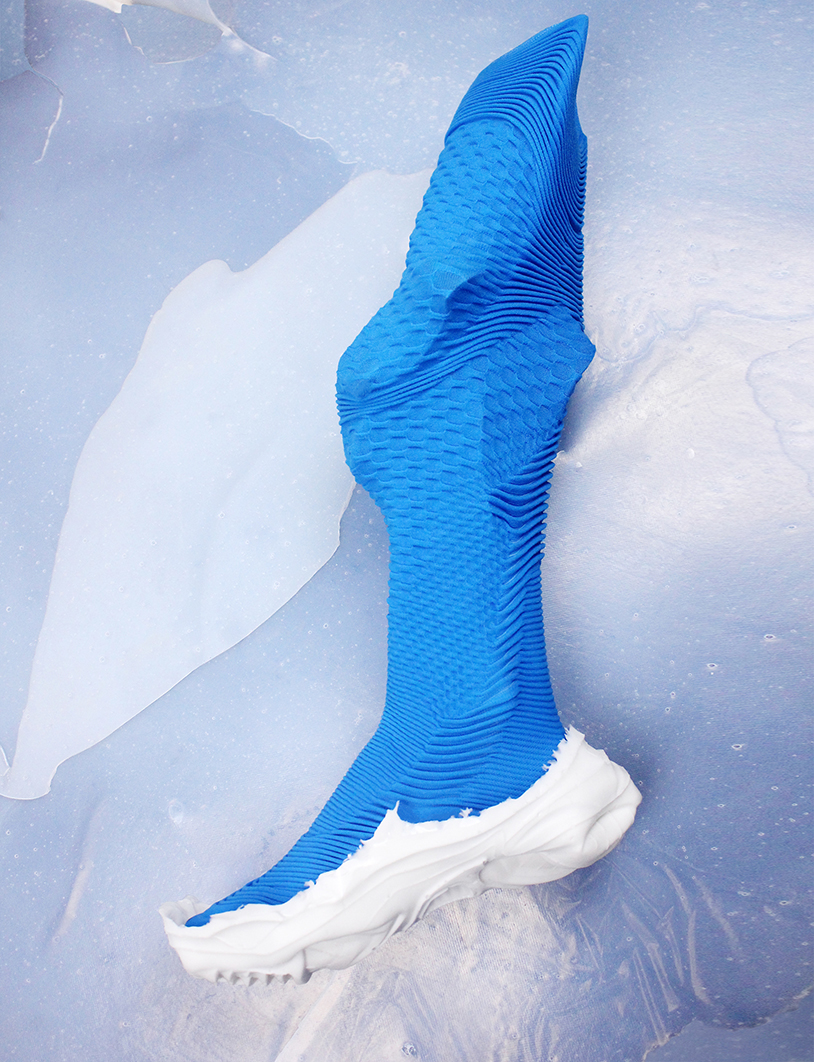

shoe design and circular knitting combined

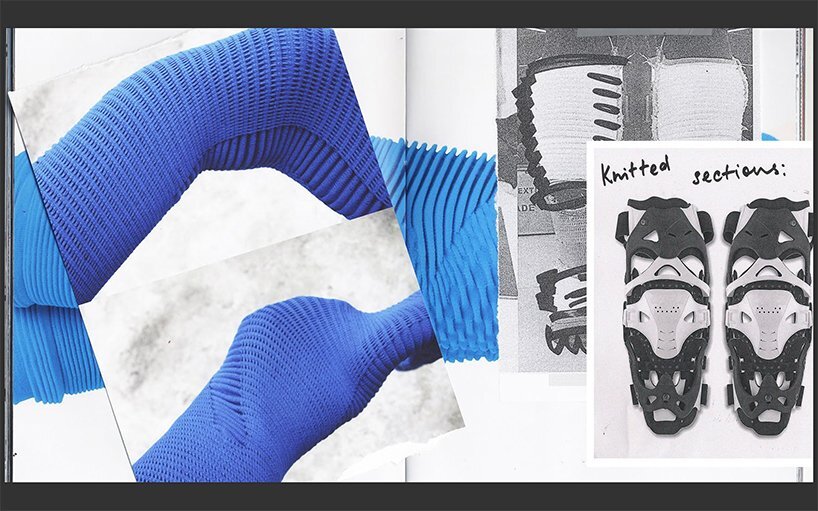

polina krichko introduces the NDVI project, aiming to apply circular knitting technology to footwear design. the resulting highly-functional compression knit pieces are based on human anatomy, with patterns derived from motorcycling protective gear. above all, the design is developed with an awareness of the functionality and biomechanics of the foot.

all images courtesy of polina krichko, unless stated otherwise

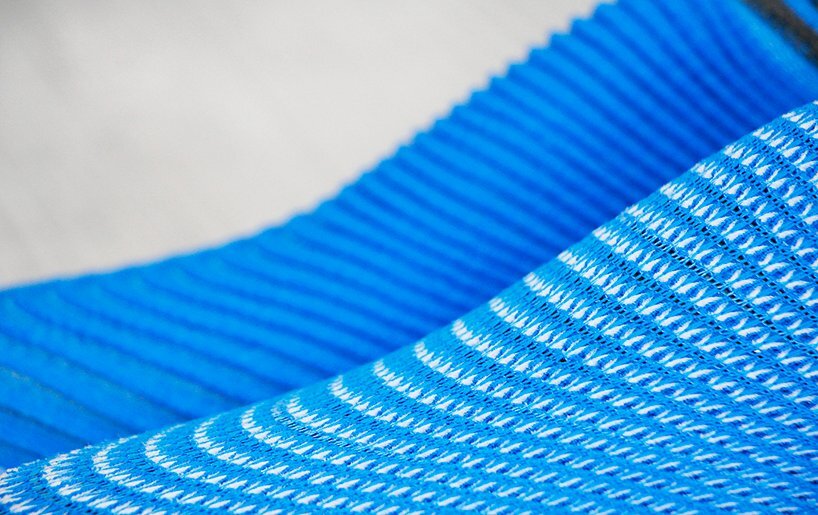

intricate surfaces of compressive patterns

all pieces are produced on circular machines which create a seamless cylinder fabric with stable pressure control. ‘the structure I used gathers fabric on the inside, giving different patterns and degrees of compression,’ shares poline krichko. ‘intricate surface design is revealed by turning the knit inside out. very fine knit exposes layering and textures in the movement,’ she adds.

the helsinki and moscow-based designer has reproduced a selection of knee-high pieces with the use of highly-functional yarns, like CELLIANT®, dryarn, and sorona (in no direct relationship or collaboration with any of the manufacturing companies). CELLIANT is a blend of natural, thermo-reactive minerals and trace elements which are non-conflict and ethically sourced. CELLIANT transforms your body’s heat into full-spectrum infrared energy, promoting local circulation and cell oxygenation while keeping you drier and at the perfect temperature. and that means more energy, endurance, strength, stamina, comfort, quicker recovery, and better sleep. dryarn is an incredibly lightweight polypropylene yarn with improved breathability and insulation properties. due to the low thermal conductivity, dryarn has excellent insulation properties, while it also has built-in moisture management properties. last but not least, sorona is an eco-efficient performance fiber made in part from annually renewable plant-based ingredients. it’s spandex-free, yet provides superior stretch and recovery. it’s produced with PDO —a building block with endlessly versatile potential— and using a biological process. knitted pieces were developed with the expertise and support of shanghai-based knitting machinery producer santoni.

full knitted shoe on a soft sneaker sole

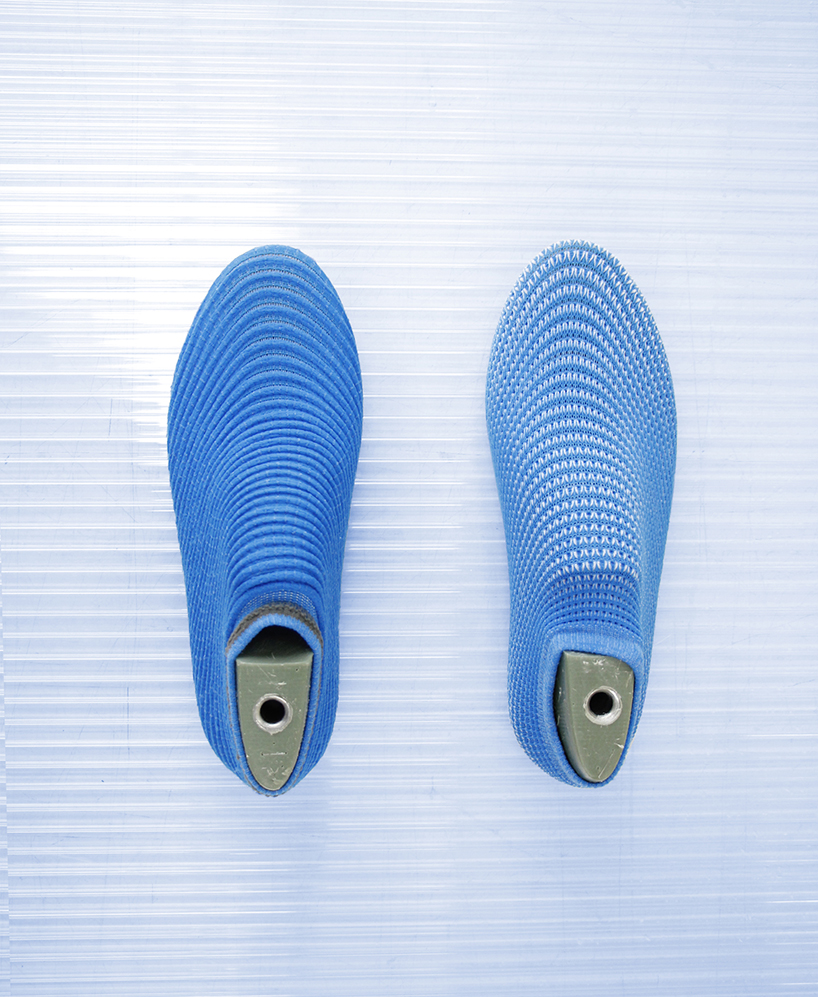

compression structures in their expanded form

fine-tuning density and elasticity for shoe uppers

image courtesy of jenny holma

image courtesy of jenny holma

image courtesy of jenny holma

project info:

name: NDVI

designer: polina krichko

designboom has received this project from our ‘DIY submissions‘ feature, where we welcome our readers to submit their own work for publication. see more project submissions from our readers here.

edited by: myrto katsikopoulou | designboom