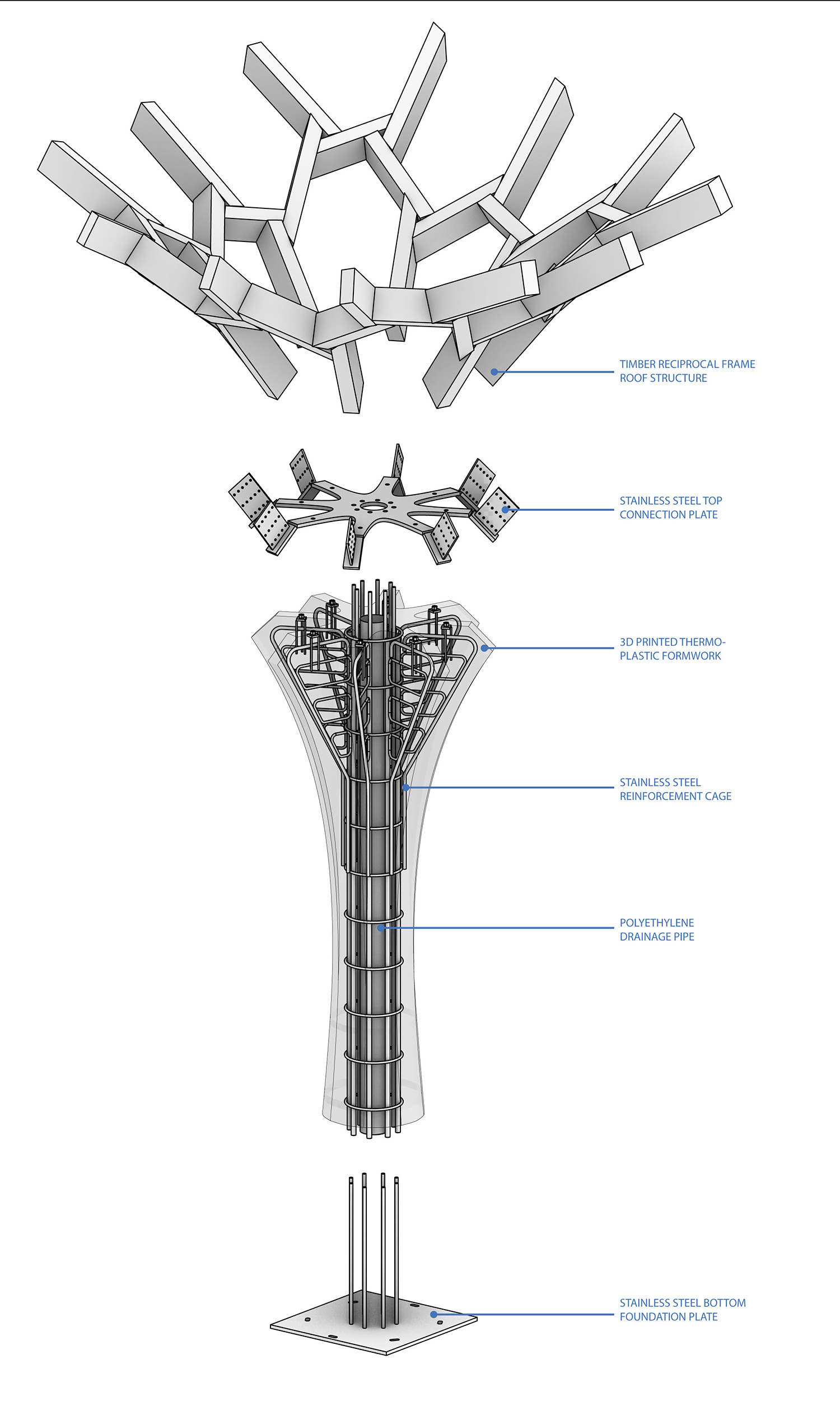

the future tree is surrounded by the office on one side and garden on the other side

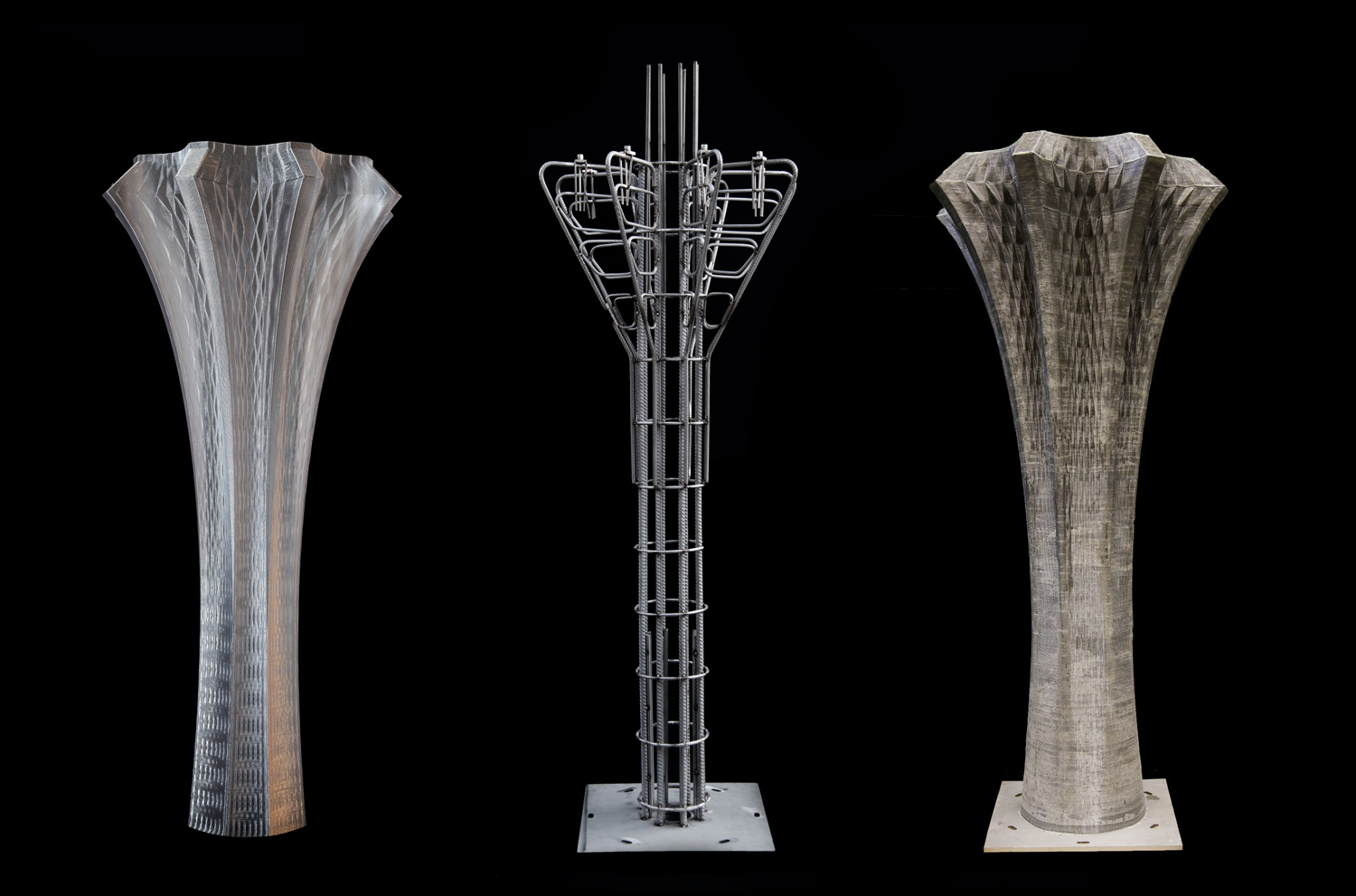

image © gramazio kohler research, ETH zurich

KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

happening now! Fiverr and designboom are thrilled to announce the winners of Revive on Fiverr, a global competition that called on architects and designers to breathe new life into abandoned spaces through adaptive reuse.

the founder of jiakun architects, is recognized for his humanistic approach, crafting spaces that combine the everyday with the utopian.

connections: 39

see how architects and designers transformed neglected buildings into stunning, sustainable spaces through Fiverr and designboom’s global competition!

connections: 2

the opening exhibition is the largest-ever presentation of the institution’s collection, presenting four perspectives on art history since 1950.

winding stairways and rooftop terraces carve out a labyrinthine journey through the red sol resort.