twist by Michael Blois from canada

designer's own words:

this submission developed from an idea for a project that i undertook as an undergraduate in architecture school. the project was concerned with the human body and its relationship and interaction with architecture. as a part of the larger project, i presented a door handle mechanism inspired by automotive and product design. many handles and openers in these industries are latches, pulls or sliding mechanisms that closely follow the motion of opening the door or the component part. i asked the question: why do we not interact with architecture in the same way that we interact with our products and furniture?

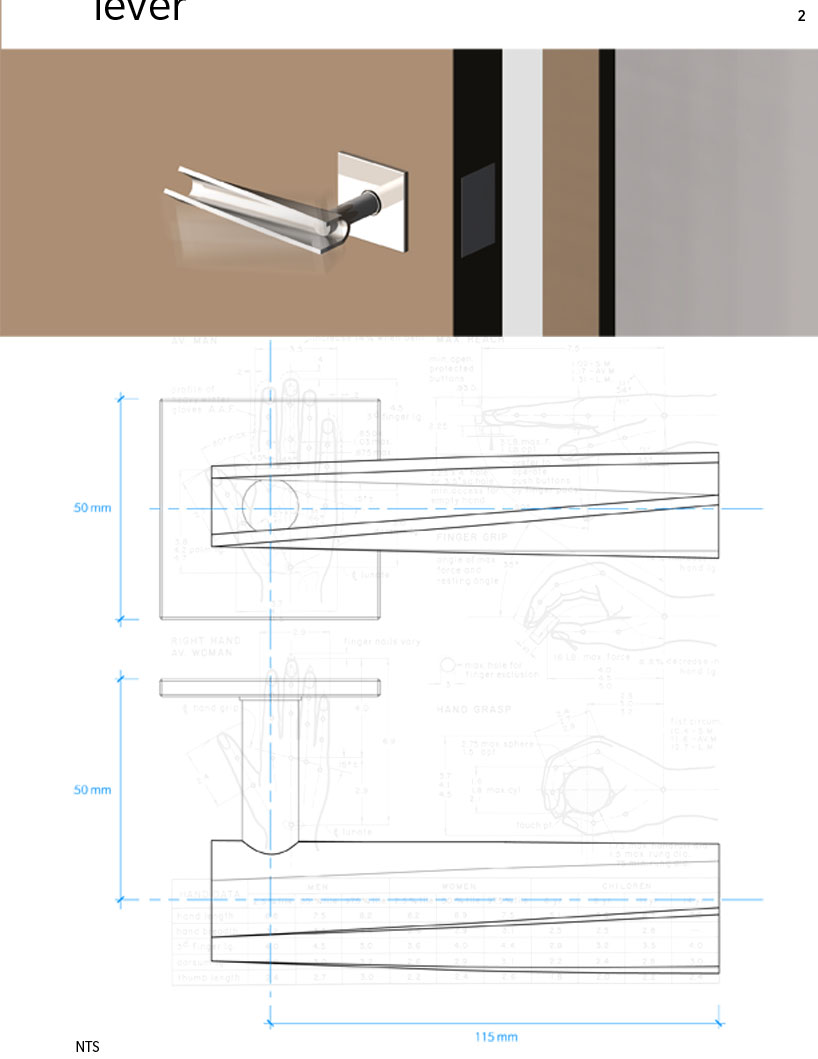

this submission is divided into two parts; the first being the design of a lever handle that operates within current standards. the second part is a further developed attempt to answer that question i posed as an undergraduate student. the rotated lever handle relies on the standard latch mechanism – with a slight modification in the extent of rotation required to retract the latch. an additional routed (radial) slot and metal channel keep the top post of the handle on track. the result extends the motion of opening or closing the door into the act of de-latching it from the door jam.

together, the twisted handle profile and the rotated lever handle seek to enhance our interaction with architecture. on its own the twisted profile is simple, comfortable, and pleasurable to use. through its proportions and mix of hard edges and soft curves, the handle is inviting to the touch and responds accurately to the position of the human hand as it reaches to open a door. i had a lot of fun revisiting this idea and I am excited by the potential of this design!

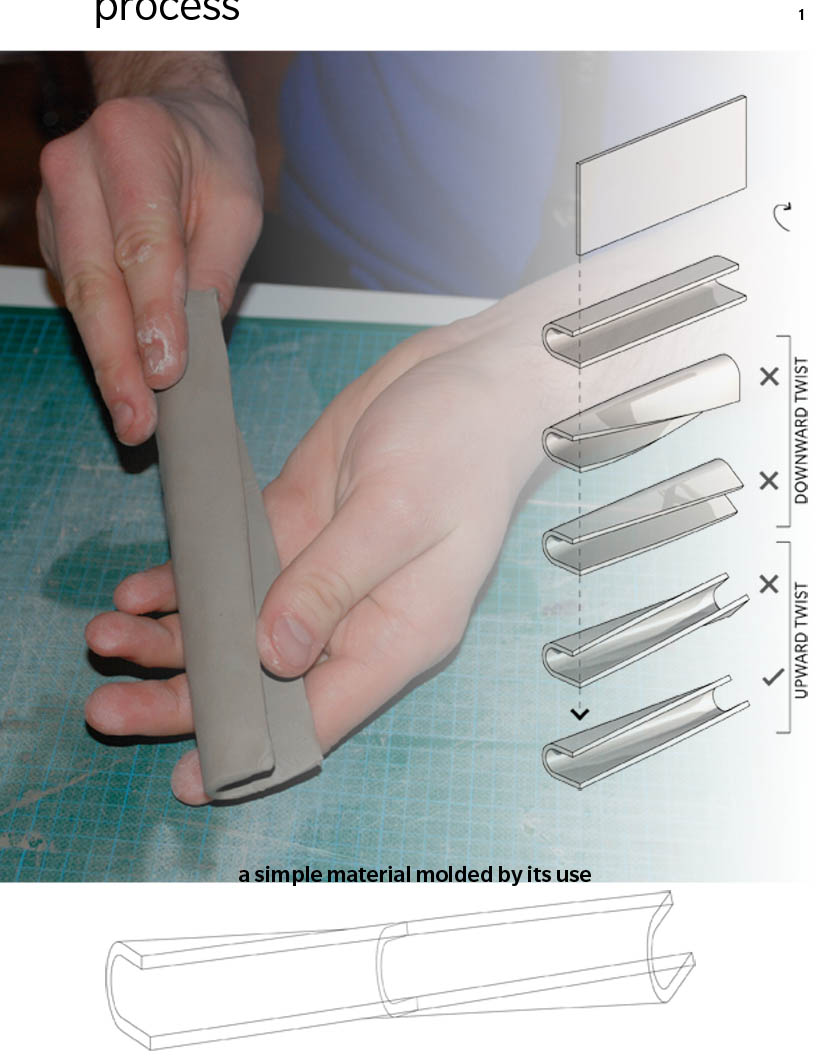

notes: through clay model testing, i discovered that my initial downward twisting profile was actually uncomfortable and it moves the hand outside of its comfortable range of motion. instead, an upward turn projects the handle into the hand as it reaches down toward the handle. edges and corners are represented as sharp edges for clarity in presentation. the actual product would have a 0.5mm bevel for safety. conceptually the profile is 3mm thick stainless steel, rolled and twisted into shape – actual manufacturing techniques may be different. some further development is required on the modified mechanism including the top channel on the freestyle portion of the submission.

page 1_process

page 2_lever

page 2_lever

page 3_freestyle

page 3_freestyle