design and construct your own furniture with 3D printed joints

all images courtesy of ollé gellért

world wide furniture company ikea already has everyone putting together their own bookcases, tables, beds, lights, but hungarian industrial designer ollé gellért, wants to take out the middle man, with a collection of 3D printed joints called ‘print to build’. the idea is not a moonshot, but a clear realization on where the furniture industry could be going in the future because of the steep price decline of 3D home printers.

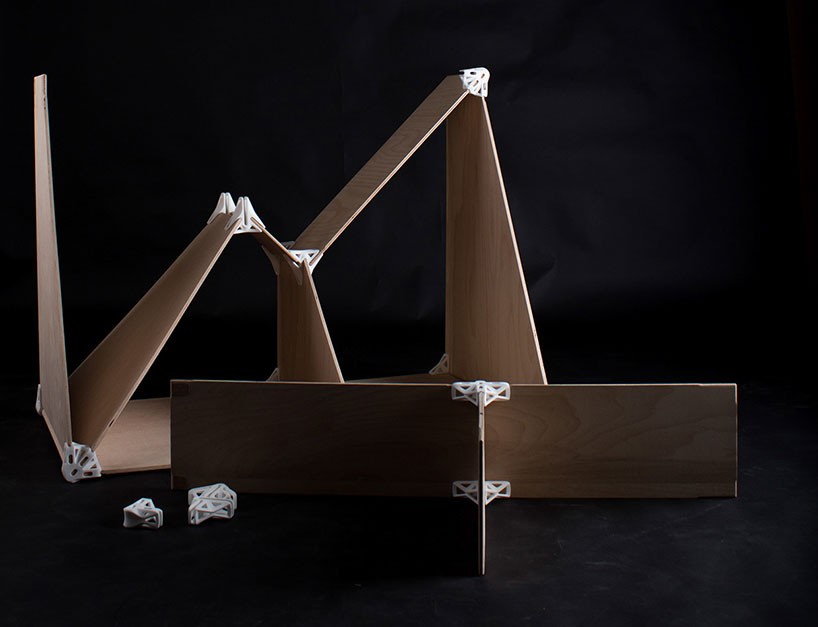

a sample bookcase built from the 3D printed joints

a sample bookcase built from the 3D printed joints

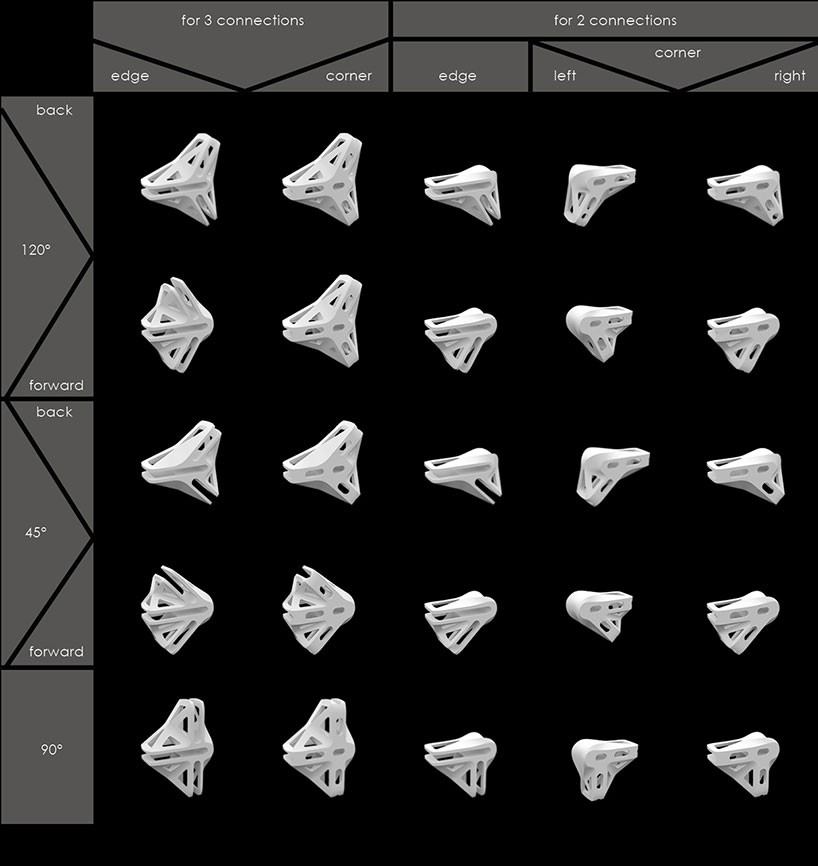

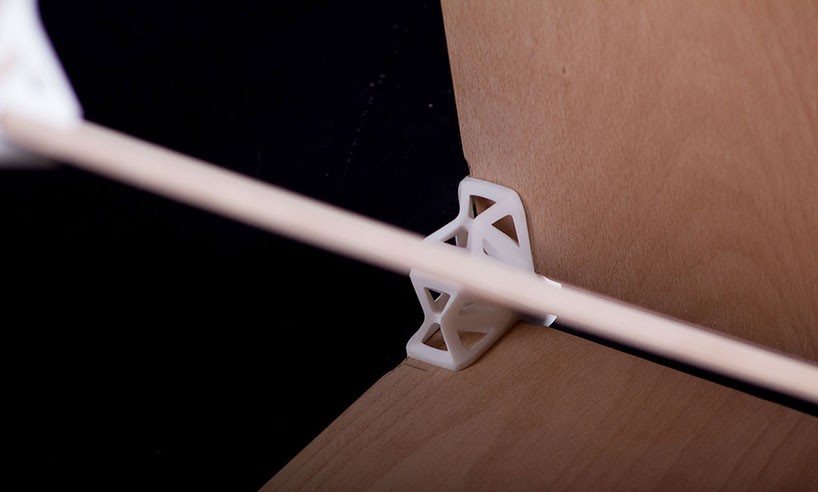

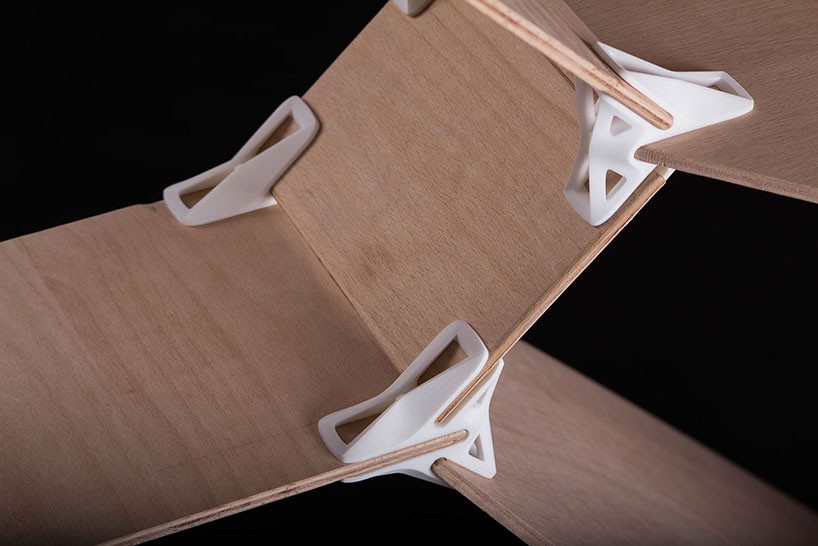

to design and construct large objects, ollé narrowed his research, developing and printing just the small joints that are able to connect bigger parts that can be made an assortment of different materials. the joints connect eight millimeter plywood sheets together in a variety of different angles – 90, 45, and 120 degree elements. the key factor to the design of the ‘print to build’ set of joints is the unnecessary need for screws, glue, allen keys or special tools. ollé gellért wants to draw attention to the importance of changing our thinking as to how we build furniture with the help of 3D printers, which in turn, would stop our epidemic addiction to ikea catalogues.

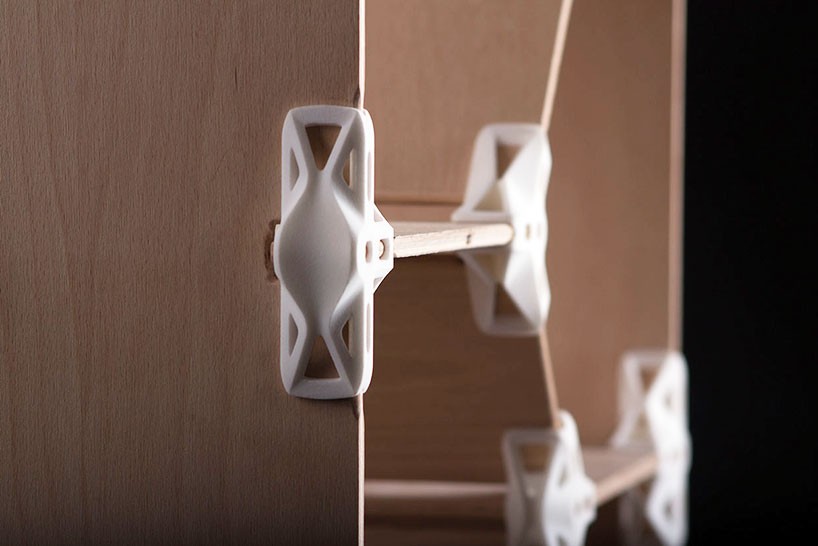

no need for glue or screws during the construction process

no need for glue or screws during the construction process

the different sets of joints

the different sets of joints

made from durable plastic

made from durable plastic

the 90 degree joint

the 90 degree joint

the 45 degree joint

the 45 degree joint

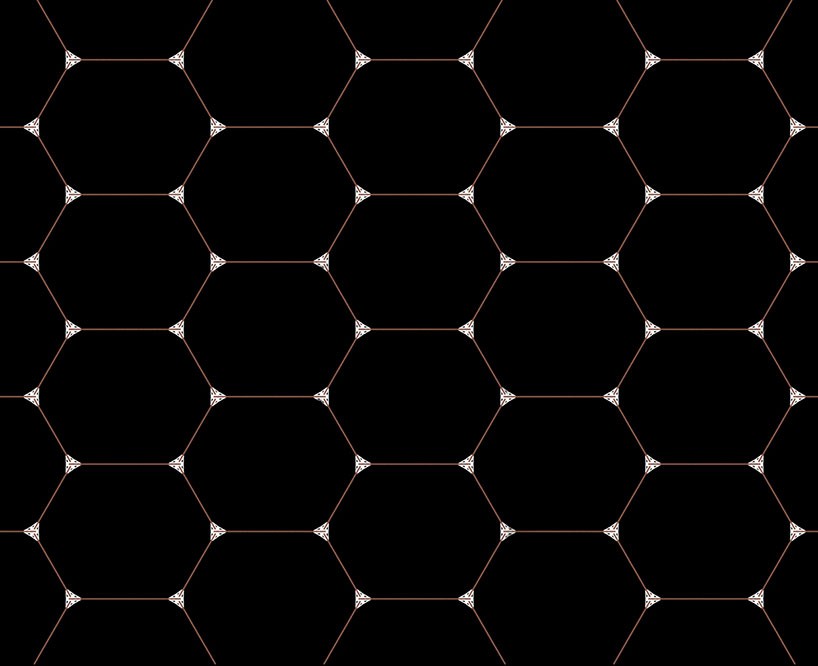

the 120 degree joint

the 120 degree joint

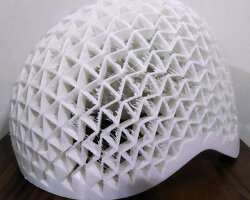

the 120 degree pattern

the 120 degree pattern

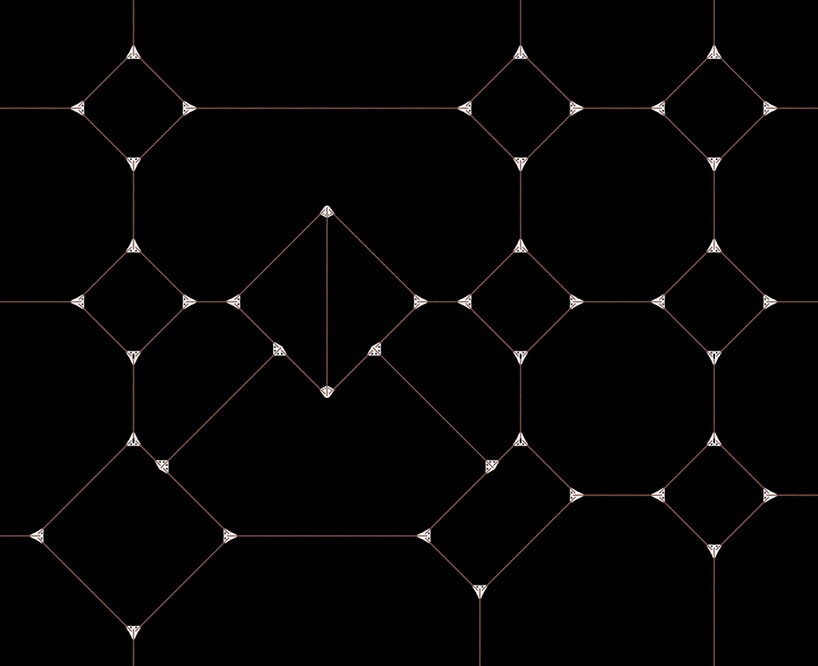

the 45 degree pattern

the 45 degree pattern

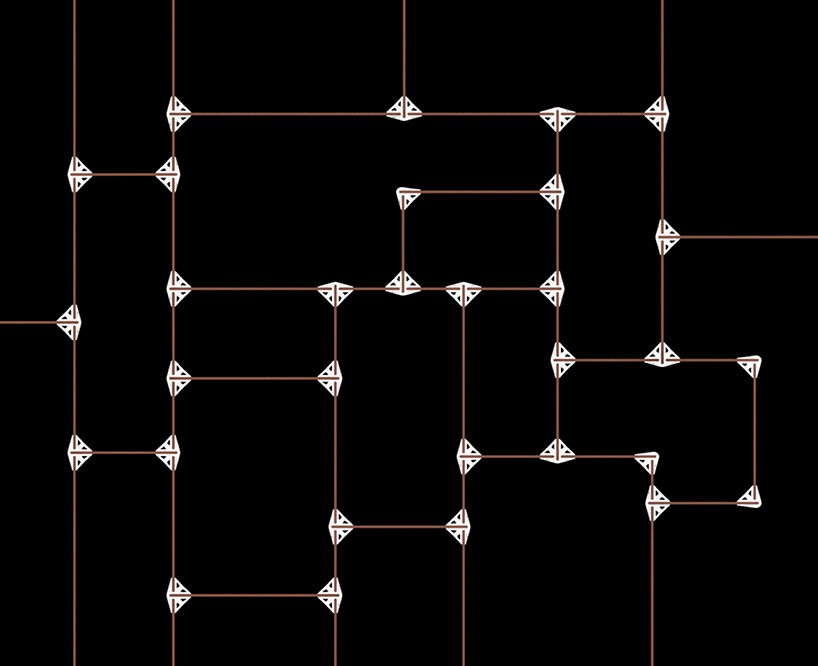

the 90 degree pattern

the 90 degree pattern

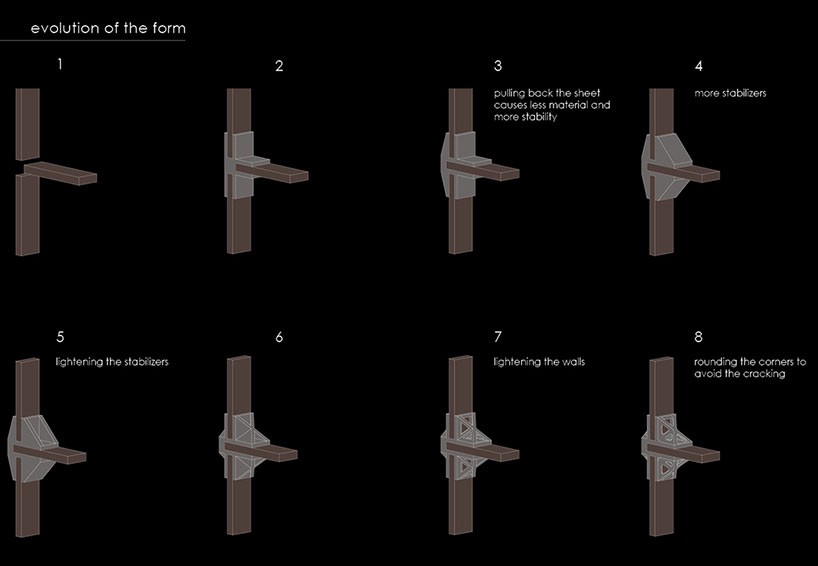

the evolution of the joint

the evolution of the joint

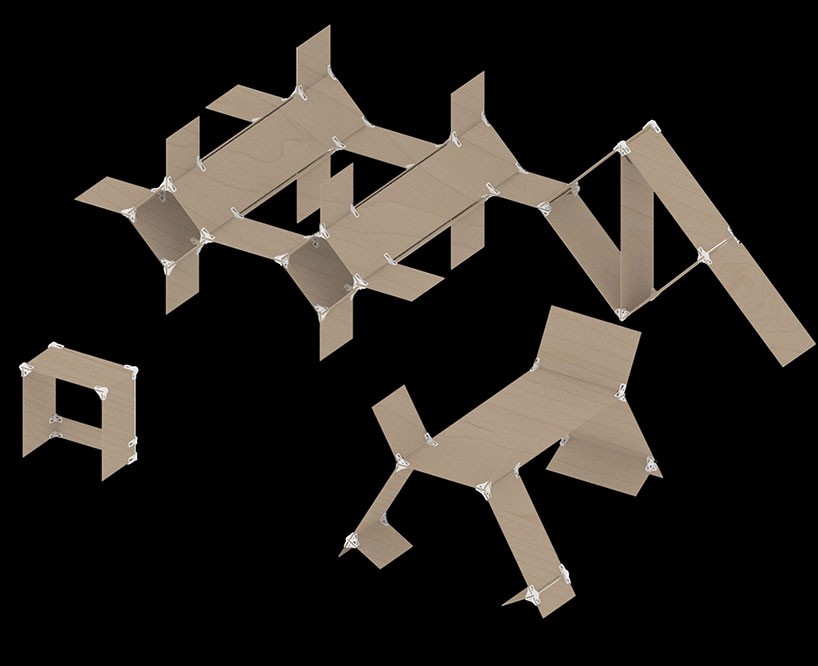

3D renderings of the furniture

3D renderings of the furniture

the pieces use eight millimeter plywood

the pieces use eight millimeter plywood

a free standing side table

a free standing side table