Michele di Carlo introduces concept shoe design, 4Steps

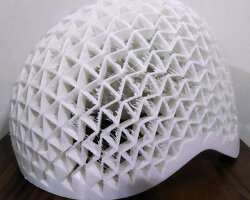

Product designer Michele di Carlo conceptualized 4Steps, a concept design series of customizable and adjustable 3D-printed sneakers for kids aged between 6 and 14. These kicks can be disassembled and stretched so that the shoes can fit their extending feet, up to five different shoe sizes. The adjustable sneakers weigh only around 123 grams, making them lightweight. They also incorporate molded parts with a honeycomb structure for extra lightness and breathability. Making these shoes for kids 3D-printed adds to the airiness of 4Steps. In this case, as the kids run around, they don’t need to exert extra energy to drag or carry the footwear every chase they take.

images courtesy of Michele di Carlo

adjustable 3D-printed sneakers for kids

So far, Michele di Carlo has already produced a prototype of his adjustable 3D-printed sneakers for kids using Filafex filament, a type of thermoplastic polyurethane, for softness and durability. It is still a concept shoe design, but 4Steps can pose a number of advantageous potentials both for the kids wearing them and the environment, as the product designer says. A sock crafted from a 3D technical fabric used in automotive applications can also be produced to go along with the concept shoe design. These adjustable 3D-printed sneakers for kids can be personalized in terms of their designs and styles of sides and uppers.

Michele Di Carlo’s 4Steps features molded parts with a honeycomb structure

3D-printed sneakers 4Steps can be customized

When Michele di Carlo says that 4Steps can be customized, he means that the kids can choose colors through a dedicated online configurator or create their own designs by uploading their personal logos and characters, and the 3D printer will handle the rest. He also means that all of the shoes’s parts are replaceable, separable, and disposable for easy recycling and repair. They can wear their custom 4Steps until they’re 15 years old. They just need to ask someone’s help, or they themselves may be able to do it, to disassemble the adjustable 3D-printed sneakers.

retail of the shoe’s retractable heel mechanism

Then, the kids or supervising adults refit the adjustable sneakers with retractable heels to their new feet size and put all the pieces and strings back again. The elastic strings that hold up the shoes together and can be unclipped help make 4Steps easily adjustable. During warm seasons, the open honeycomb structure allows air to pass through the sneakers, while during cool seasons, an extra layer of socks may be needed to ward off the cold.

detailed front view of the adjustable 3D-printed sneakers for kids

Michele Di Carlo first unveiled 4Steps as his innovative thesis project at the Università di Camerino in Italy back in 2017 but has kept the torch burning by making progress, the prototype included. With his adjustable 3D-printed sneakers for kids, he wanted to address the pressing issue of eco-sustainability in the footwear industry, where a pair of running shoes alone can generate 30 pounds of carbon dioxide emissions.

the upper is made from a 3D knitted elastic fabric derived from automotive applications

He saw 3D printers as a potential solution to lessen the environmental impact of traditional manufacturing, and combining them with his aim to make resizable sneakers for children, a target demographic for the footwear industry, could enable him to help reduce the number of discarded shoes. As of publishing the story, Michele Di Carlo’s 4Steps is still a concept sneaker design, and he has yet to share new progress on his adjustable 3D-printed sneakers for kids.

the sole and the cover are pieces printed with a common 3D printer and are replaceable

the shoe has 3 parts: sole, upper, cover, all separable, replaceble and disposable

a clip that shows how 4Steps can be stretched to fit the new shoe size of kids

Michele di Carlo’s 4Steps is concept adjustable 3D-printed sneakers for kids

project info:

name: 4Steps

designer: Michele Di Carlo

designboom has received this project from our DIY submissions feature, where we welcome our readers to submit their own work for publication. see more project submissions from our readers here.

edited by: matthew burgos | designboom