‘expo boulevard’

serving as the main entrance to the world expo 2010 site, the ‘expo boulevard’ is covered by a membrane roof with total surface area of 65,000m2. in addition to having a free span of almost 100 m, the roof, located on the south side of the huangpu river, is carried by 19 interior and 31 exterior masts and by six funnel shaped framework shells consisting of steel and glass. it has a height of 45 m and a free projection of 80 m. these so called sun valleys direct natural light into the basements of the ‘expo boulevard’.

the design and development of the ‘mega structure’ roof was completed by knippers helbig advanced engineering, a german company specializing in lightweight roof constructions. meanwhile, the design of the boulevard was the winning competition entry by architectural practice SBA from stuttgart.

funnel shaped framework shells

funnel shaped framework shells

the membrane roof obtained its current shape through three fundamental steps of development. first, the structuring of the large scale triangles did not only take static demands into consideration, but also accounted for numerous constraints imposed by streets, bridges and tram stations, which were already allocated in the layout. this overall planning also had a restrictive impact on the height of the exterior columns.

masts

masts

with the help of wind suction cables and hangers, the centre masts minimize the distortion of the membrane during strong wind conditions and bear a major part of the vertical loads. the inner connection rings and double layered membrane serve to distribute weight and re-inforce the membrane at the inner load concentration points.

mast detail

mast detail

there are up to nine main cables connected to the head of a mast. the membrane is fixed to each sun valley at a couple of points in order to fit it tightly around the funnel. the reliable transition of the bearing loads at the back stays and at the foot of the masts posed a particular challenge for the designers as every modification of the geometry implied a change in the distribution of forces within the membrane.

funnel framework made from steel and glass

funnel framework made from steel and glass

the head and the foot of the masts consist of cast steel mounted on ball bearings. the connection plates are up to 2 m long to avoid the collision of fork connectors. the shaft of the mast head and the connection plate are made of one cast to simplify the assembly process.

detail

detail

during heavy rain periods, the roof structure basically drains the water towards the inner masts. to counteract accumulation of components. an additional membrane is used to constitute the link between the inner ring and the lower drainage point called the ‘feed hopper’. in doing this, the main membrane is more than four meters away from the visitors; and backwater or packing of snow can not cause damage on the main roof structure.

interior

interior

funnel opening

funnel opening

construction shots of ‘expo boulevard’

construction shots of ‘expo boulevard’

detail

detail

construction of the building frame

construction of the building frame

workers cleaning the glass

workers cleaning the glass

drainage system

drainage system

diagram showcasing load bearing points of cable membrane

diagram showcasing load bearing points of cable membrane

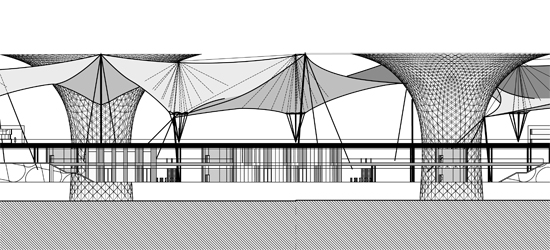

elevation view

elevation view

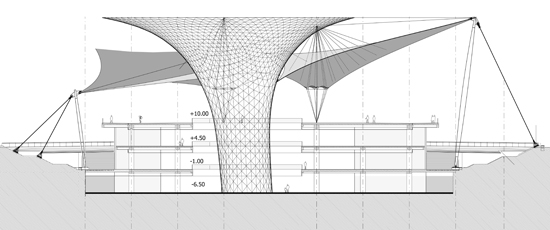

cross section view

cross section view

details of inner mast

details of inner mast

mast diagram

mast diagram

sun valley profile

sun valley profile