black vase with white weld

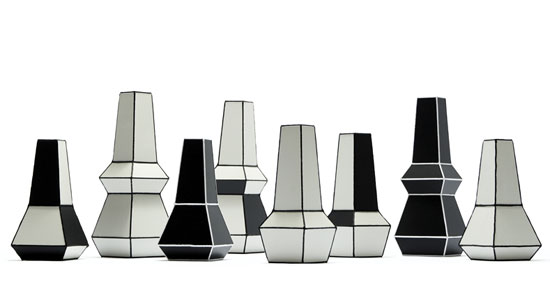

‘weld vases’ by UK-based designer phil cuttance take a bit of a departure from the typical machine-made mass replicated plastic vessels. here, cuttance has individually hand-crafted each of his vases through hot air welding, a process that is commonly used to repair broken plastic parts, joining thin plastic shapes together to create strong, distinctive edges. the plastic from the vases are made from discarded off-cut pieces of ABS plastic from a local london plastic fabricator, and each vase is individually numbered on the base.

white vase with black weld

white vase with black weld

the vases are available in three tonal combinations: black with white weld white with black weld mixed with both black and white faces and black weld (the mixed vases have randomly selected combinations of black and white faces to use up extra off-cut pieces).

they are also available in three shapes: tall (37 x 13.5 cm), high waisted (26 x 13 cm) and low waisted (28 x 12 cm)

mixed black and white vases with black weld

mixed black and white vases with black weld

‘weld vases’

‘weld vases’

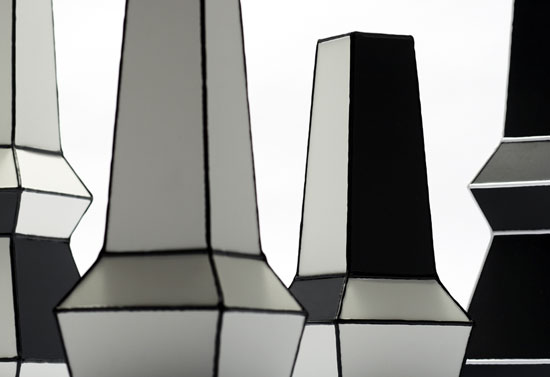

up close

up close

group shot from above

group shot from above

front view

front view

‘weld vases’

‘weld vases’

production of the ‘weld vases’:

plastic offcuts from a local london fabricator are used to produce the vases

plastic offcuts from a local london fabricator are used to produce the vases

cutting the off-cut plastic on the table saw

cutting the off-cut plastic on the table saw

the individual faces of the vases cut to the correct template shapes

the individual faces of the vases cut to the correct template shapes

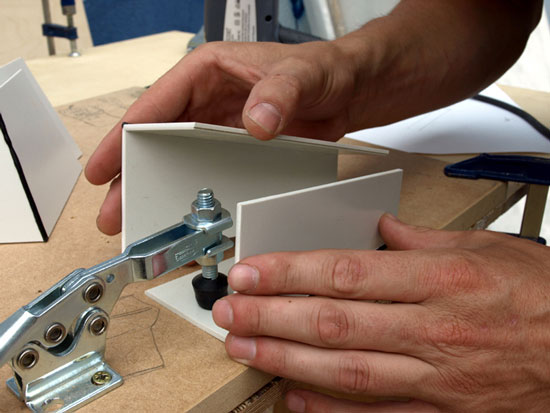

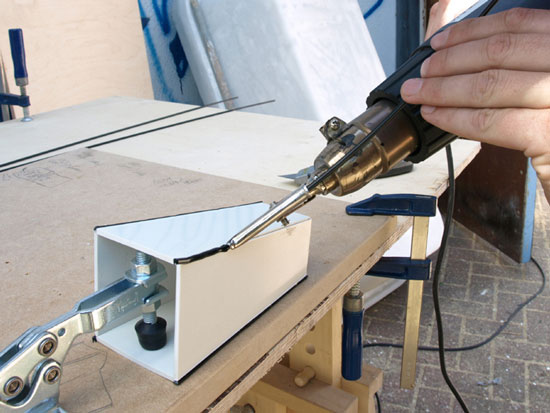

tacking two faces together before welding

tacking two faces together before welding

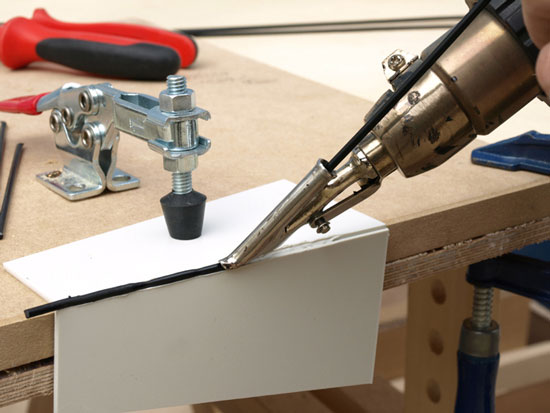

welding faces of the vase together

welding faces of the vase together

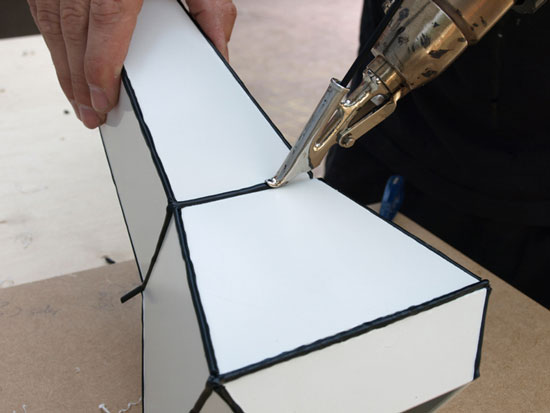

welding faces of the vase together

welding faces of the vase together

set-up for welding two halves

set-up for welding two halves

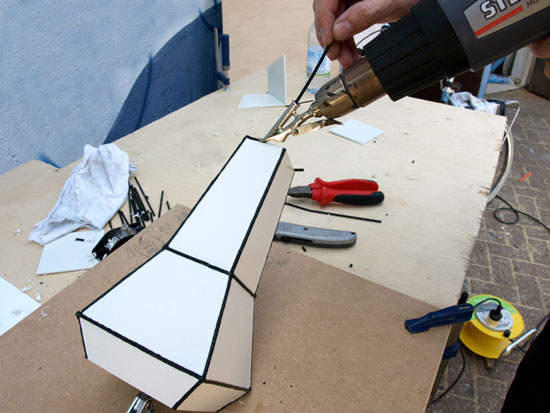

the halves being welded together

the halves being welded together

two halves being welded together

two halves being welded together

three individual parts of one of the vases

three individual parts of one of the vases

planing the edges

planing the edges

aligning the top of a vase

aligning the top of a vase

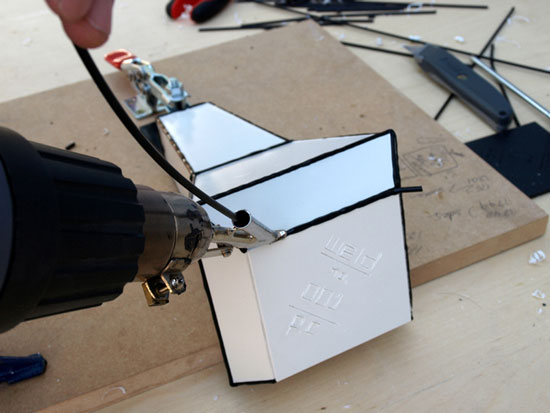

welding the top to the base

welding the top to the base

welding the top edge

welding the top edge

scribing vase number on base

scribing vase number on base

welding on the base

welding on the base

a completed ‘weld vase’

a completed ‘weld vase’