airbus subsidiary 3D prints working motorcycle frame from high-strength aluminum alloy

all images courtesy of ap works

ap works, a subsidiary of airplane manufacturer airbus, exhibited the wide applicability of 3D manufacturing with an ridable electric motorcycle that weighs just 35 kilograms. equipped with a six kilowatt motor, the bike accelerates in a few seconds to 80 km/h.

video courtesy of airbus

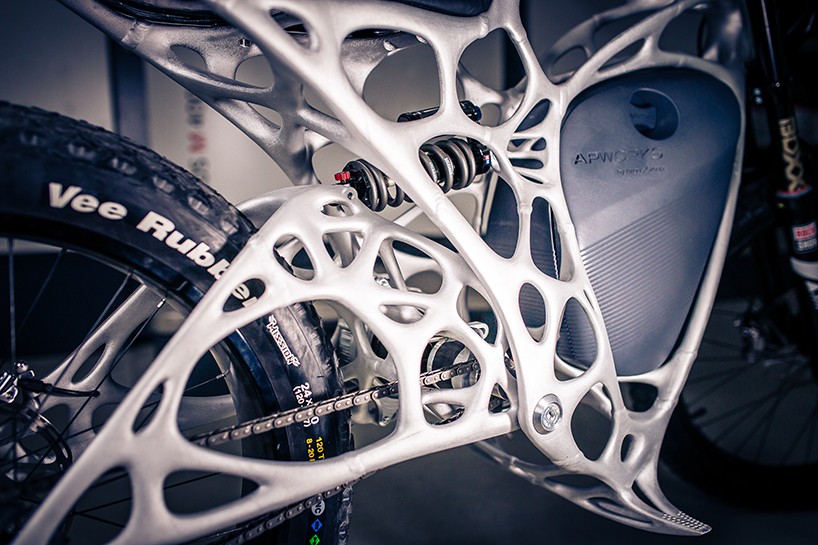

it was originally produced from billions of particles of special aluminum allow, which were welded by laser sintering. the main frame was based on theoretical algorithms to create the best structure to accommodate the loads occurring during riding. the result is an organic layout similar to an exoskeleton found in nature.

the ap works motorcycle includes a six kW electric motor

the elaborate construction using the same algorithm could be implemented in other industries creating similar outcomes in design. the hollow frame enables wires and cables to run through the whole structure, with all the mounting points integrated together.

the hollow frame enables wires and cables to run through the whole structure

the corrosion-resistant aluminum alloy has very similar specific strengths to titanium – an exceptional level of ductility allows the material to be deformed just before breaking. this ability makes it particularly interesting for numerous applications in robotics, automotive and aerospace industries. ap works plan to 3D print 50 limited edition frames for the public to enjoy.

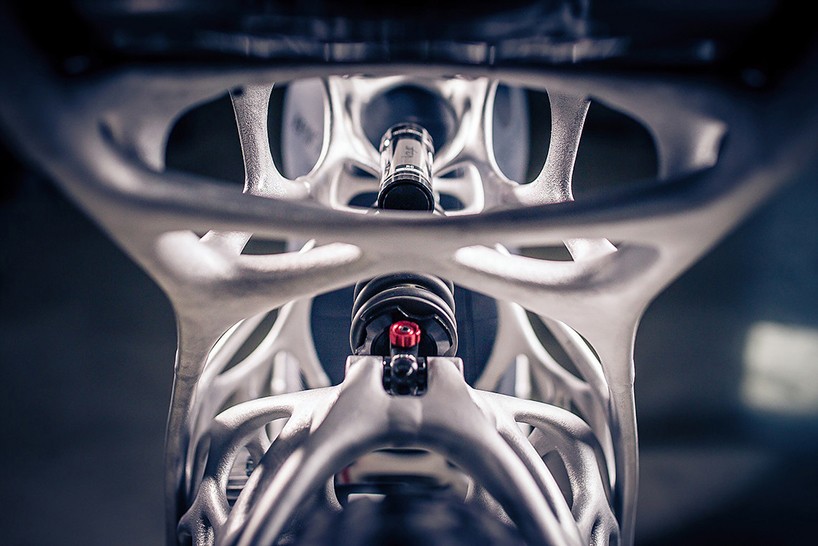

two main pieces make up the whole frame

inside the hollow frame

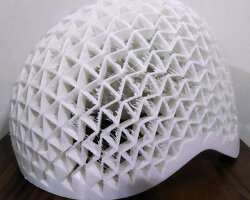

the 3D printed technic uses laser sintering

the front fork arch

rear suspension tucks away inside the frame

the main unit houses the battery

the rear taillight